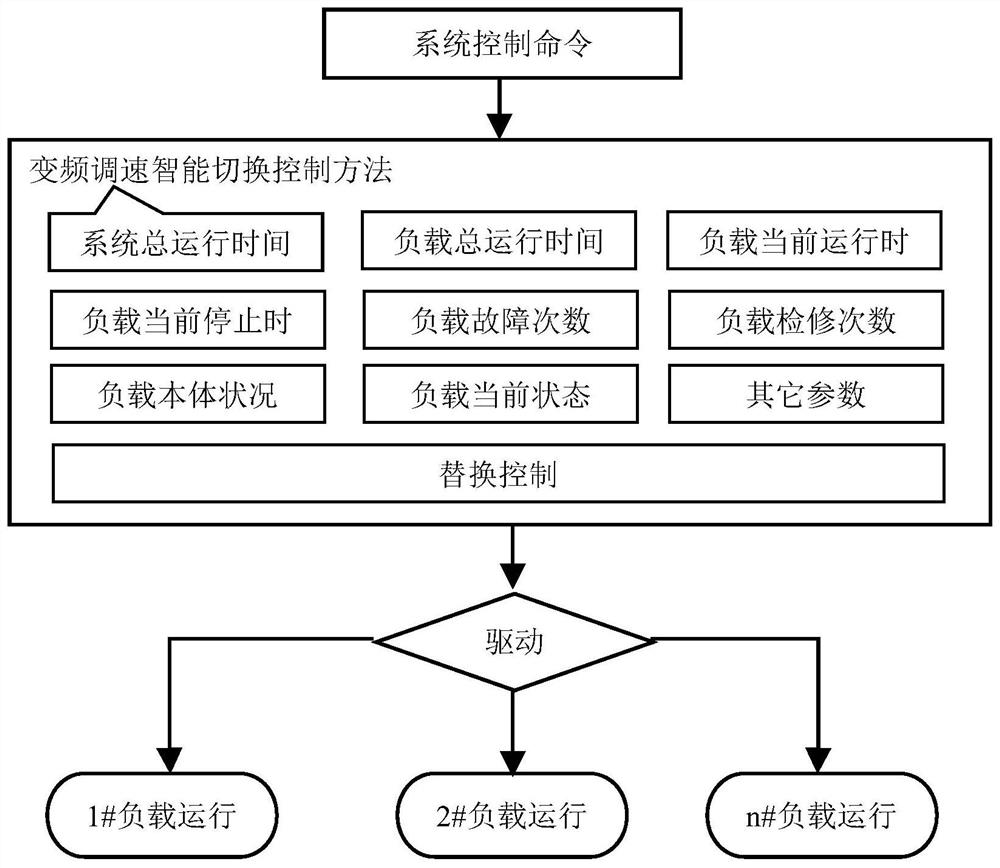

Intelligent switching control method and system of variable frequency speed regulation multi-load system

A technology of intelligent switching and frequency conversion speed regulation, which is applied in the direction of control system, AC motor control, electrical components, etc., can solve problems affecting production safety, equipment overage service, equipment overuse, etc., to improve production efficiency and production safety factor, The effect of improving safety production coefficient and avoiding safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] Embodiment 1. The intelligent switching control method of a variable frequency speed regulation multi-load system described in this embodiment includes the following steps: monitoring and recording the total running time of each load in the system;

[0040] When the total running time of a certain load is close to the overhaul time limit of the load, an overdue warning message and a load replacement command are issued; the load replacement command includes information about the load to be replaced;

[0041] Monitor and record the current running time of each load in the system, and issue a load replacement command when the current running time of a certain load exceeds the rated continuous running time of the load;

[0042] When a "load replacement command" is detected, select a replaceable device for the load to be replaced as a backup device, and control the backup device to start, replace the load to be replaced to continue working, and control the replacement load to...

Embodiment approach 2

[0048] Embodiment 2. This embodiment is a further supplement to the intelligent switching control method of a variable frequency speed regulation multi-load system described in Embodiment 1. In this embodiment, a step is added: monitor and record the number of failures of each load;

[0049] And it is further defined that the method of selecting a replaceable device of the load to be replaced as the backup device is: selecting the device with the least number of failures among all the replaceable devices of the load to be replaced and which is in a stopped state as the backup device.

[0050] The number of failures of the load described in this embodiment refers to the cumulative sum of the number of failures that have occurred since the load was put into use for the first time, until the parameter is reset to zero after the load is replaced.

[0051] This embodiment defines the principle of selecting a backup device, that is, selecting a device with a small number of failures ...

Embodiment approach 3

[0052]Embodiment 3. This embodiment is a further supplement to the intelligent switching control method of a variable frequency speed regulation multi-load system described in Embodiment 1. In this embodiment, a step is added: monitor and record the number of inspections of each load;

[0053] And it is further defined that the method of selecting a replaceable device of the load to be replaced as the backup device is: selecting the device with the least number of inspections and in a stopped state among all the replaceable devices of the load to be replaced as the replacement device.

[0054] The number of overhauls of the load described in this embodiment refers to the sum of the number of times the load has been overhauled since it was put into use for the first time, and this parameter is reset to zero after the load is replaced.

[0055] This implementation mode limits the principle of selecting the backup equipment, that is, select the equipment with the fewest maintenanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com