Tempura flower frying machine

A tempura flower fryer and fryer technology, which is applied in food ovens, food processing, baking, etc., can solve the problem that continuous automatic production cannot be realized, the appearance and color of tempura flowers are different, and the blanking flow is not constant. and other problems, to achieve the effect of controllable frying time, easy large-scale manufacture and installation, and reduction of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

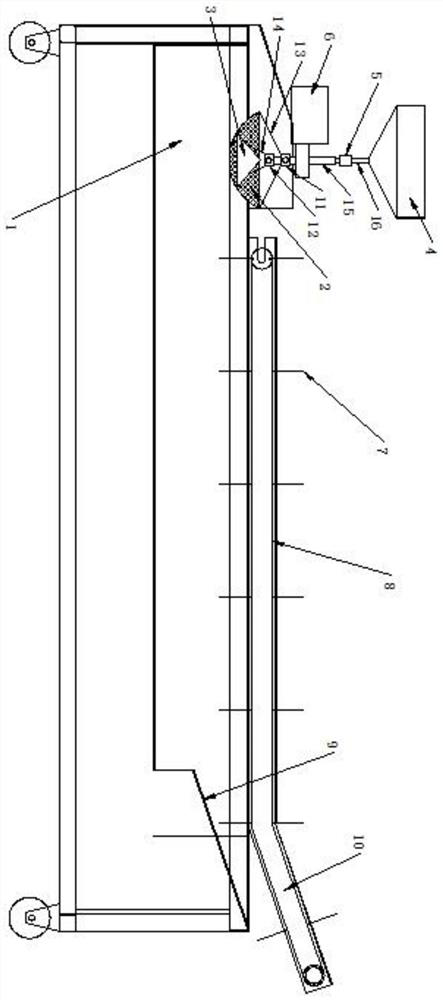

[0035] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0036] Such as figure 1 As shown, the tempura flower frying machine includes a frying box 1, and a throwing net 2 is installed on the top of the frying box 1 for rotation.

[0037] The top of the net 2 is also provided with a slurry hopper 4.

[0038] A flow control valve 5 is also provided on the discharge port of the slurry hopper 4 .

[0039] Also be provided with shunting mechanism in the net 2 of getting rid of.

[0040] Frying tank 1 is also provided with several baffles 7 which move side by side near the position of the liquid surface.

[0041] The top horizontal rotation of frying box 1 is equipped with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com