A method and system for processing and reading two-dimensional codes inside transparent materials

A technology of transparent materials and internal processing, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of not providing a two-dimensional code reading method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

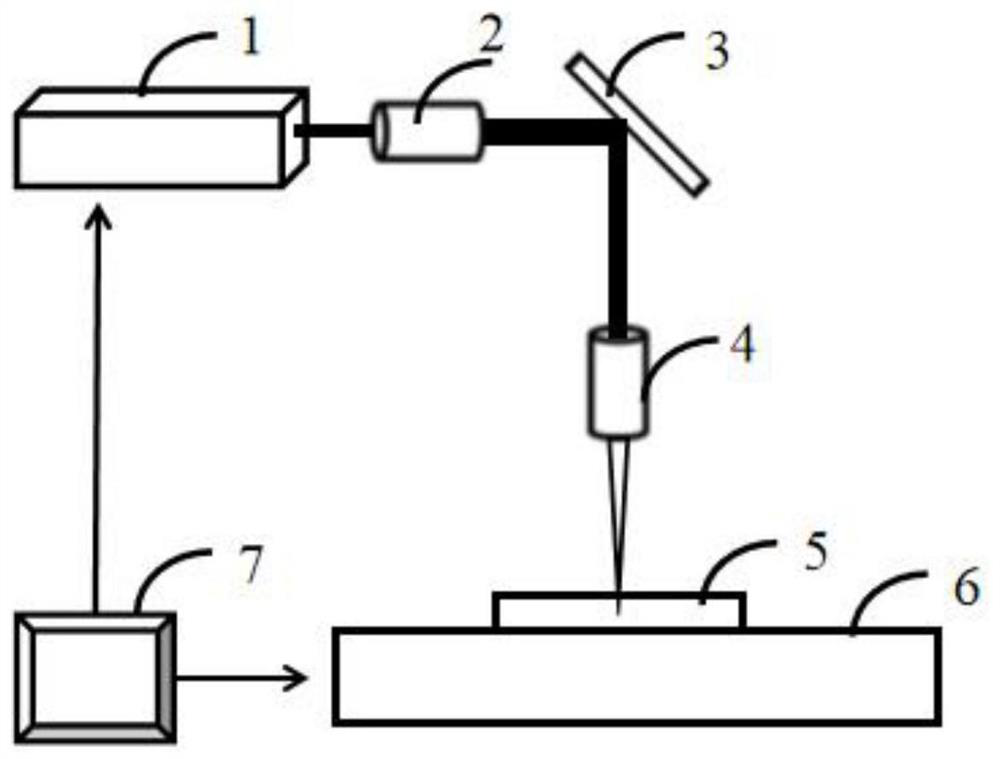

Method used

Image

Examples

Embodiment 1

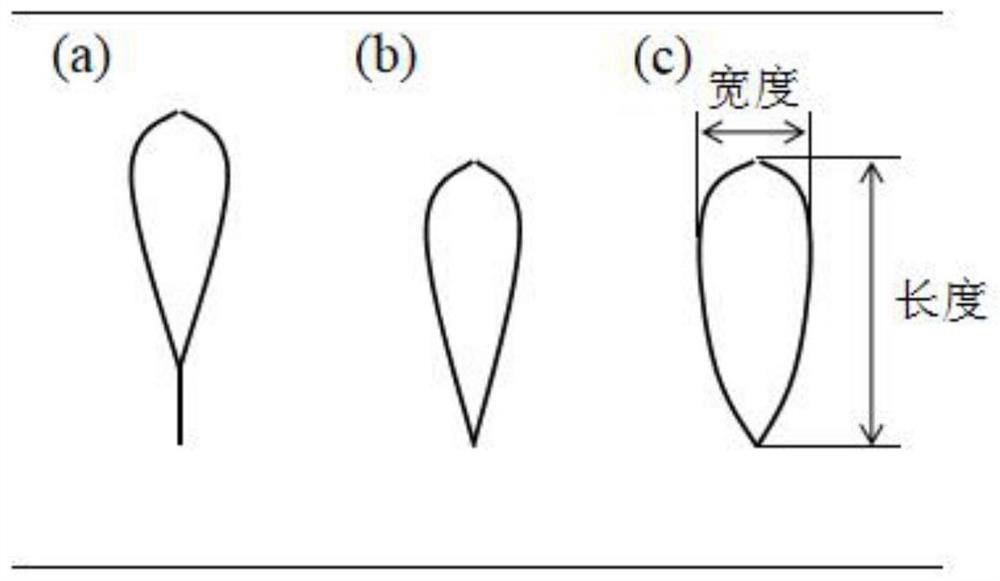

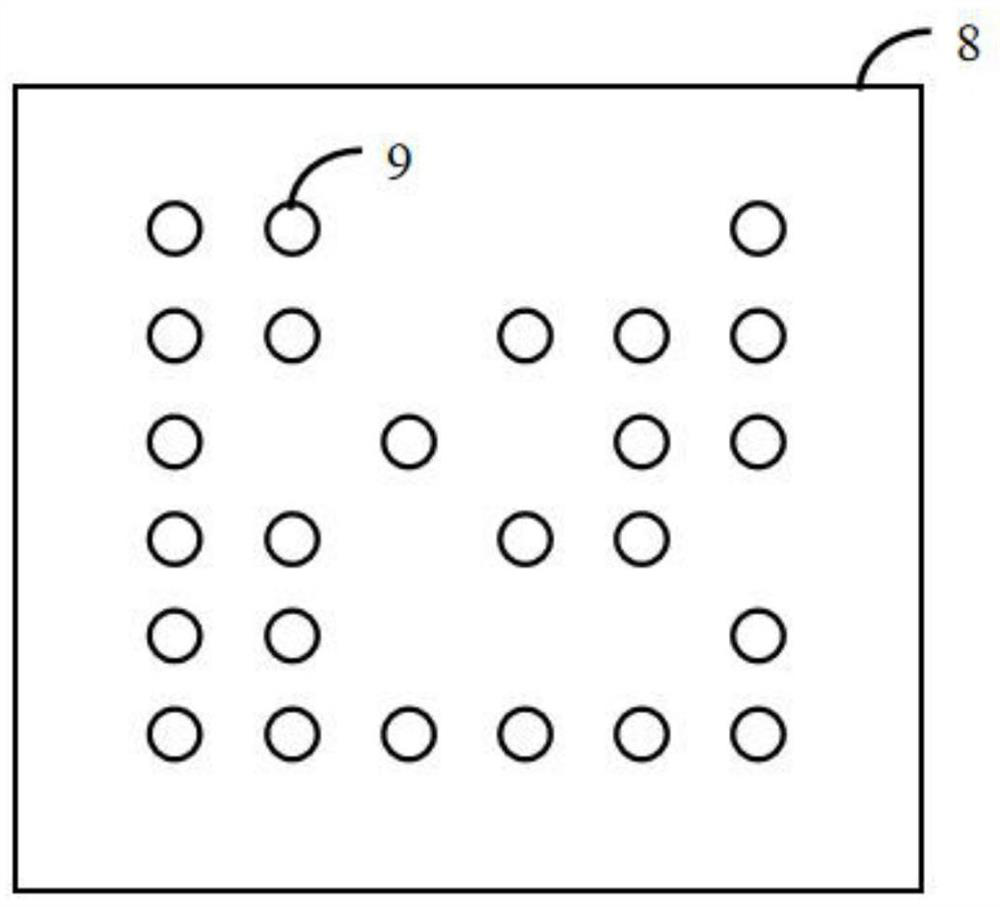

[0042] In this embodiment, an ultraviolet picosecond laser is used to code the glass coated with a smooth ink layer at the bottom, the power is 0.2W, the repetition frequency is 1MHz, the laser action time is 0.06ms, and the processing times are 1 time. It can be obtained that the length of the laser active area is 24.25 μm, the width of the laser active area is 5.45 μm, and the aspect ratio is 4.45. Under the reflected light of the side light source, a clear image can be obtained through the CCD vision system, and accurate reading is obtained.

Embodiment 2

[0044] In this embodiment, an ultraviolet picosecond laser is used to code the glass coated with a rough ink layer at the bottom, the power is 0.6W, the repetition frequency is 1MHz, the laser action time is 0.1ms, and the processing times are 3 times. The length of the laser active area is 54.84 μm, the width of the laser active area is 10.33 μm, and the aspect ratio is 5.309. The side light source is used to illuminate the two-dimensional code area, and the shadow area can be collected and analyzed by the CCD vision system to obtain a clear image and accurate reading.

Embodiment 3

[0046] In this embodiment, an ultraviolet picosecond laser is used to code the glass coated with a rough plastic layer at the bottom, the power is 0.65W, the repetition frequency is 1MHz, the laser action time is 0.1ms, and the processing times are 2 times. It can be obtained that the length of the laser active area is 45.38 μm, the width of the laser active area is 10.19 μm, and the aspect ratio is 4.453. The side light source is used to illuminate the two-dimensional code area, and the shadow area can be collected and analyzed by the CCD vision system to obtain a clear image and accurate reading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com