Main electrode water cooling mechanism of mesh enclosure tool

A main electrode and tooling technology, applied in the field of machinery, can solve the problems of high temperature at the tooling, affecting the stability of the tooling, etc., and achieve good cooling performance, high practical value, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

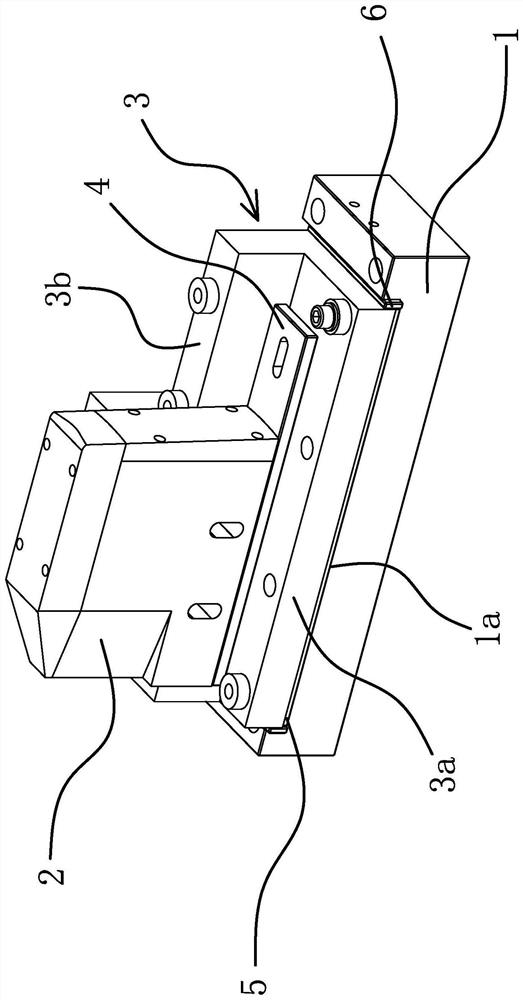

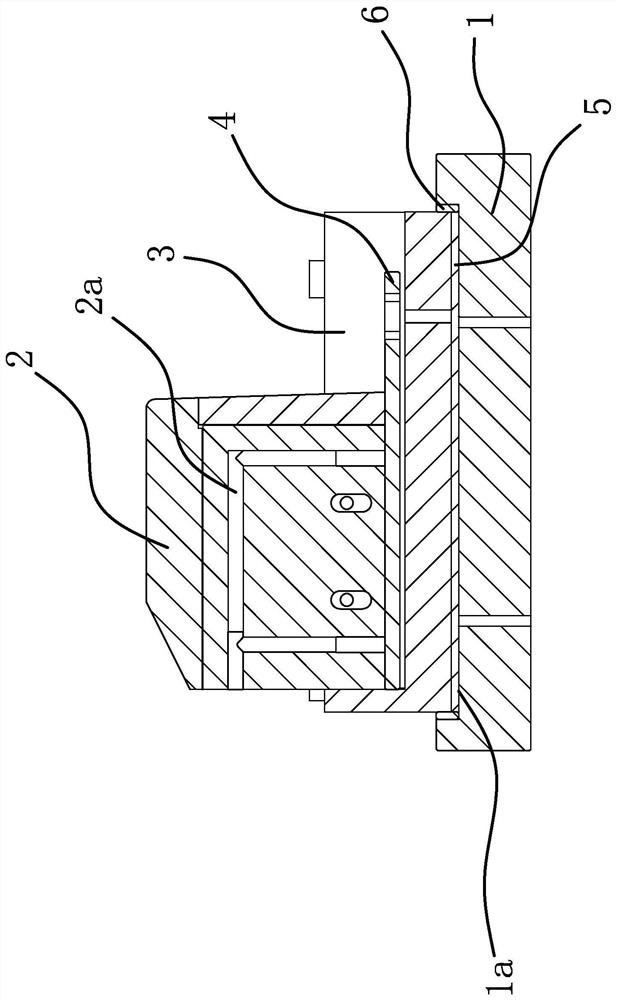

[0023] Such as figure 1 with figure 2 As shown, the main electrode water-cooling mechanism of this net cover tooling includes a fixed plate 1, an electrode block 2, a base 3, a backing plate 4 and an insulating plate. The above-mentioned fixed plate 1 is in the shape of a long plate and has a concave connection groove 1a on it. The above-mentioned electrode block 2 is fixedly connected to the base 3 and the above-mentioned backing plate 4 is located between the electrode block 2 and the base 3, the above-mentioned base 3 is matched with the connection groove 1a and the base 3 is connected to the connection groove 1a, and the above-mentioned insulating plate is located Between the base 3 and the fixed plate 1.

[0024] The electrode block 2 has a cooling channel 2a for cooling water to enter.

[0025] The base 3 includes a plate-shaped first plate 3a and a second plate 3b, the first plate 3a is arranged horizontally, and the second plate 3b is vertically fixed to the edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com