Wood processing edge straightening machine stable in cutting and convenient to adjust

A technology for adjusting motors and straight edges, which is applied to wood processing appliances, special forming/shaping machines, manufacturing tools, etc., can solve the problems of large wood errors, easy shaking, time-consuming and labor-intensive problems, and achieve the goal of improving stability and reducing errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

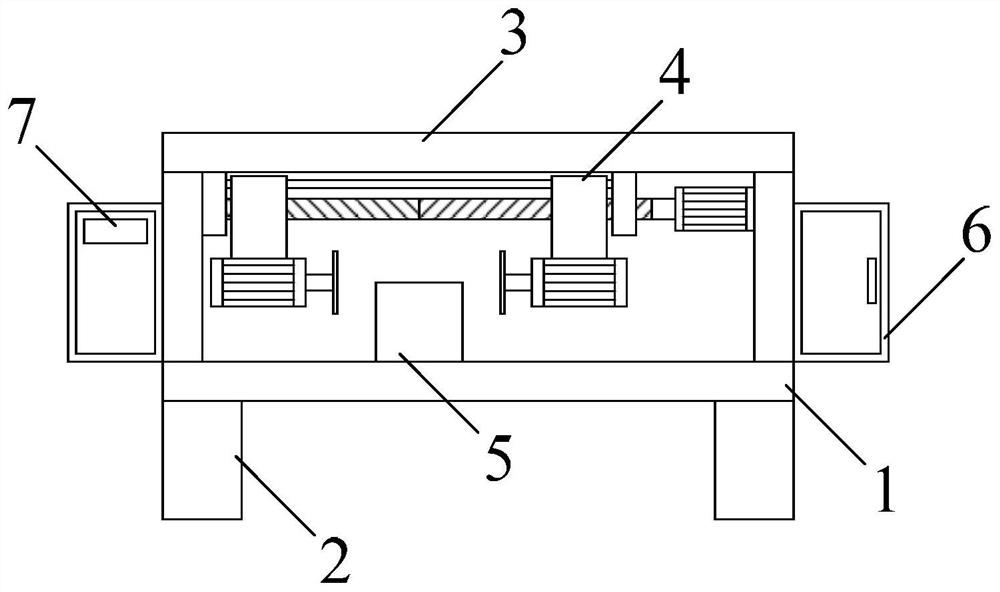

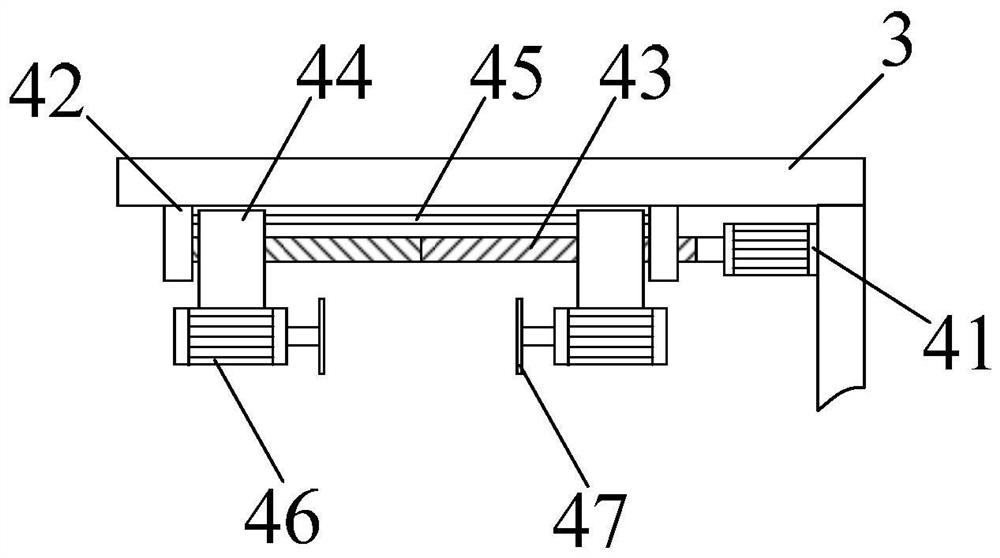

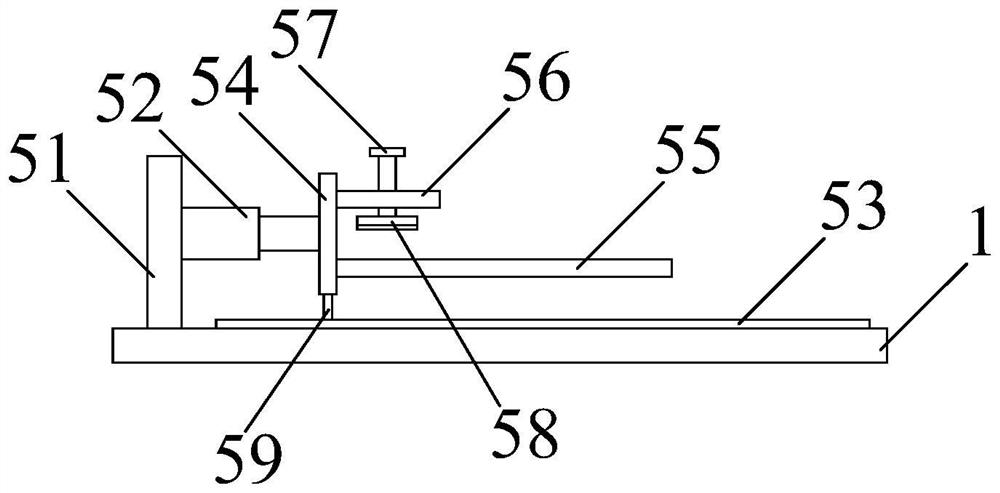

[0022] as attached figure 1 to attach Figure 4 shown

[0023] The present invention provides a straight edge machine for wood processing with stable cutting and convenient adjustment, comprising a workbench 1, support legs 2, bracket 3, straight edge component 4, push component 5, electric control cabinet 6 and PLC controller 7, the Four support legs 2 are used, and the support legs 2 are installed at the four corners below the workbench 1; the bracket 3 is installed on the outer edge of the upper rear side of the workbench 1; The electric control cabinet 6 is installed under one side of the support 3, and the electric control cabinet 6 is connected to the mains through wires; the PLC controller 7 is installed under the other side of the support 3, and the PLC controller 7 is connected through the wires It is connected with the electric control cabinet 6; the straight side assembly 4 is installed above the inner side of the bracket 3.

[0024] In this embodiment, specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com