Method suitable for flexible manufacturing production process

A production process and flexible manufacturing technology, applied in conveyor objects, conveyors, mechanical conveyors, etc., can solve problems such as inconvenience, cumbersome modification of established processes, and difficulty in reusing software and workflows, so as to improve flexibility, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method applicable to the flexible manufacturing production process described in the present invention is specifically to set the production process of the sound box, including a workbench, an ingredient warehouse, a finished product warehouse, a first transportation unit, a second transportation unit and a third transportation unit, Also include the following steps:

[0035] Step 1: Define as follows:

[0036] When at least two sub-steps are the preconditions of another sub-step, the above-mentioned sub-steps are multi-necessary relations, wherein the sub-step as a precondition is a necessary sub-step of another sub-step;

[0037] When one sub-step is the only precondition of another sub-step, the above two sub-steps are a single necessary relationship;

[0038] When a sub-step is a precondition of multiple sub-steps, the above-mentioned sub-step is a multi-sufficient sub-relationship.

[0039] where the subsequent substeps are sufficient substeps of the preconditio...

Embodiment 2

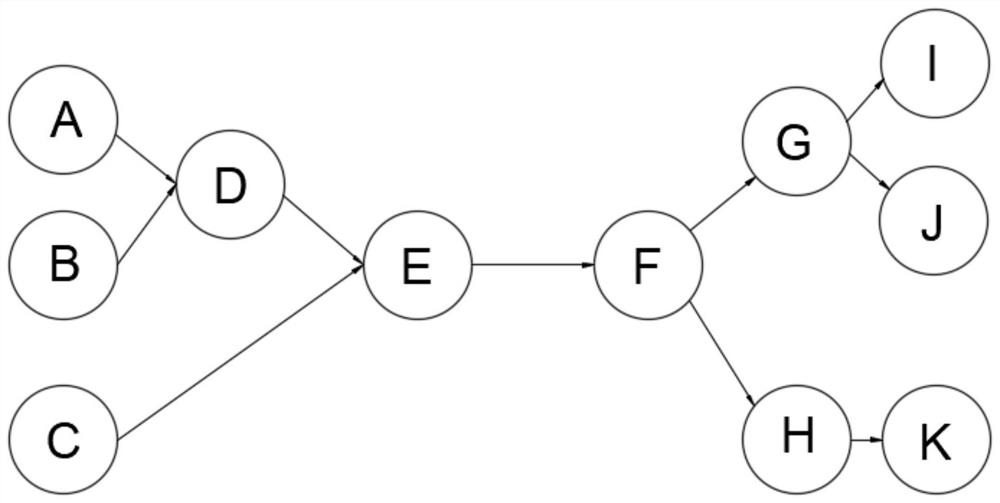

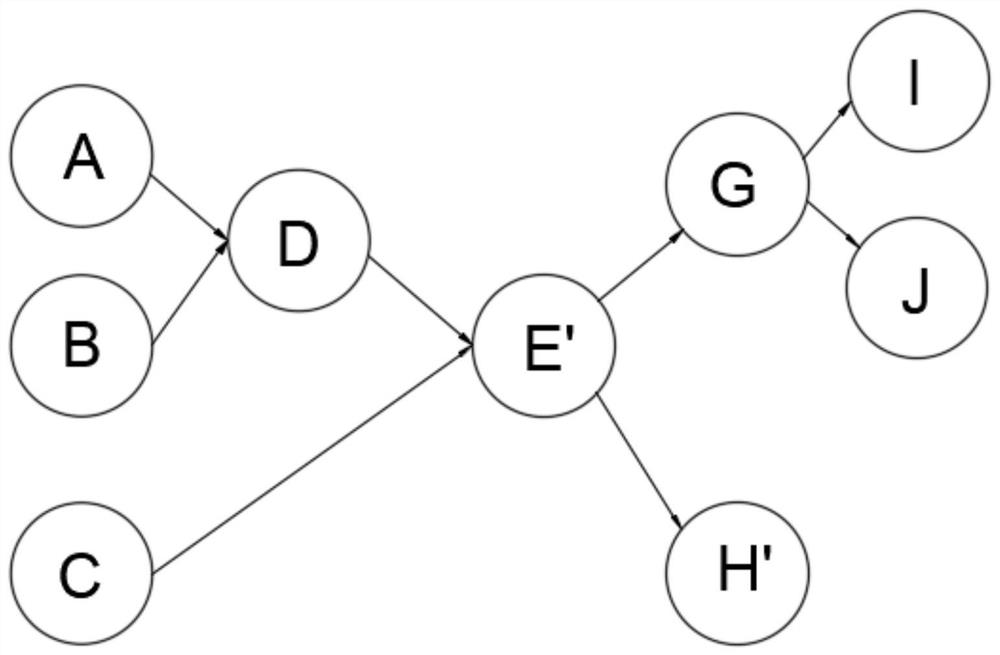

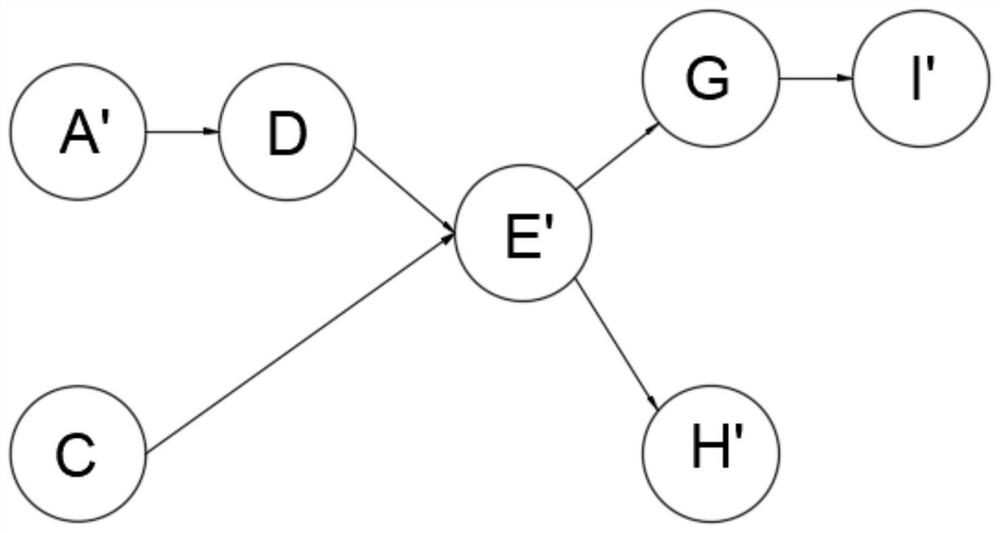

[0067] Including several transport units, material barcodes, material inlets, material racks, material temporary storage areas, material transfer areas and loading robots, several transport units are divided into the first transport unit and the second transport unit, specifically define the material loading process, define The following sub-steps:

[0068] Sub-step A: the first transport unit transports the material to the material inlet;

[0069] Sub-step B: the second transport unit prepares to transport materials at the material inlet;

[0070] Sub-step C: classify according to different types and grades of materials;

[0071] Sub-step D: scan the barcode of the material and record it;

[0072] Sub-step E: Calculate the remaining material space on the material shelf;

[0073] Sub-step F: the second transport unit transports the material from the material inlet to the material temporary storage area;

[0074] Sub-step G: The material robot in the material transfer area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com