Stirring device with built-in pins in desulfurization machine

A technology of internal stirring and pins, which is applied in recycling technology, plastic recycling, etc., can solve the problems of unstable final product quality, laminar flow, and short heating time, and achieve uneven desulfurization, uniform heating, and quality stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

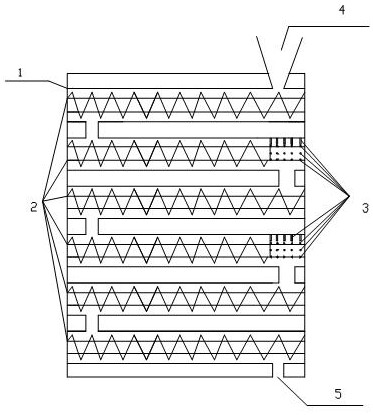

[0007] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The accompanying drawings show the structural principle of a stirring device in a desulfurizer with built-in pins of the present invention. An internal stirring device of a desulfurization machine with built-in pins, comprising a barrel (1), a transmission screw (2), built-in pins (3), a feeding port (4), and a discharging port (5). Its characteristics are: rubber material enters the machine barrel (1) from the feeding port (4), and the rubber material is conveyed to the material discharging port (5) step by step through the transmission screw (2). Among them, five rows are respectively arranged at the ends of the second and fourth layers of the transmission screw (2), and each row is provided with four pins (3), a total of 20 pins (3). After the rubber powder passes through the pins (3), the flow direction of the rubber powder is continuously controlled. Dispersion and rearrangement realize the secondary mixing process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com