Supporting method and device for ejection problem of anchor rod and anchor cable cover plate

An anchor rod and anchor cable technology, used in the installation of anchor rods, mining equipment, shaft equipment, etc., can solve the problems of roadway loss of support, low strength of surrounding rock, and easy damage, so as to improve support resistance and increase contact. area, the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

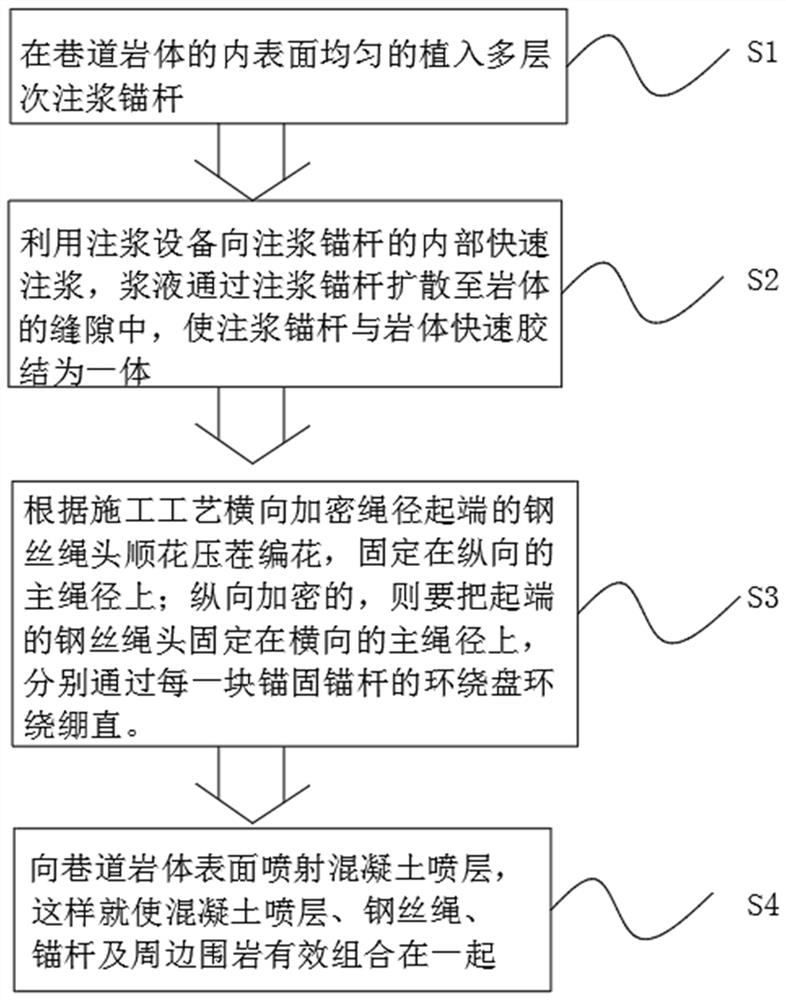

[0036] Such as Figure 1-7 As shown, a support method aimed at the ejection problem of the bolt and cable cover plate includes the following steps:

[0037] A: Spray the first layer of slurry on the inner surface of the rock mass, transport the grouting anchor (4) to the inside of the roadway, and preliminarily form the grouting anchor (4) with a predetermined length at the working position. The inner surface is evenly implanted with multi-layer grouting anchors (4);

[0038] B: Use grouting equipment to inject grout into the grouting anchor (4) through the grouting hole (9), and the expansion plate (8) of the grouting anchor (4) expands under the pressure of the grout, and at the same time inject The gas in the slurry storage tank (14) of the slurry anchor (4) is discharged into the rock mass through the transmission tank (15), and a certain internal stress is reserved in the rock mass to resist the pressure of the deep rock mass, and at the same time, the gas is injected in...

Embodiment 2

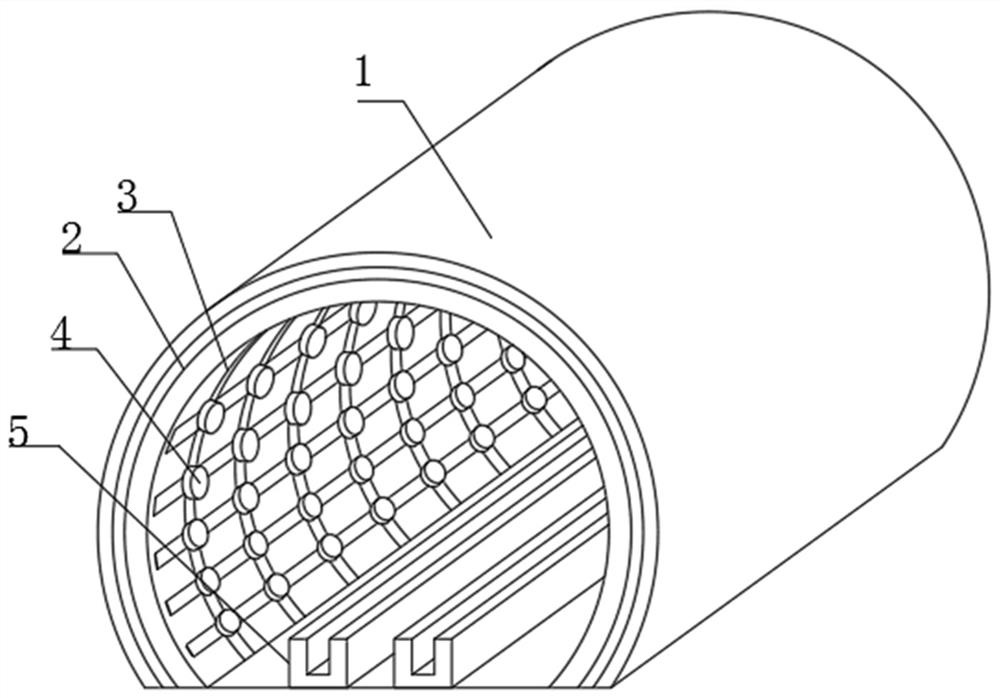

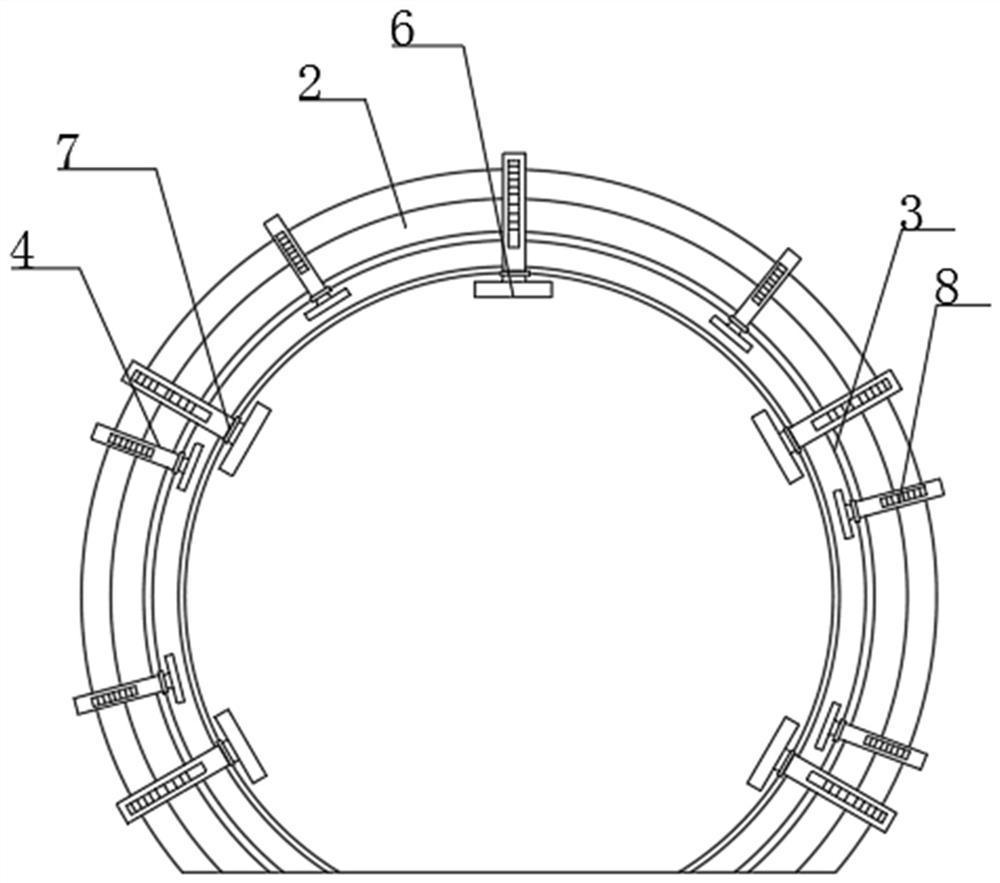

[0044] Such as Figure 2-7 As shown, a support device aimed at the ejection of the bolt and cable cover plate, including the roadway body (1), the inner bottom of the roadway body (1) is fixedly installed with the transmission track (5), and the roadway body (1) The inner wall is sprayed with multi-layer concrete spraying layer (2), and the rock mass of the roadway body (1) is evenly implanted with multi-layer grouting anchors (4), and the middle part of the grouting anchors (4) is connected with a steel wire rope net (3 ), the concrete sprayed layer (2), the steel wire mesh (3) and the grouting anchor (4) are combined to form the steel wire rope mesh (3) with the steel wire mesh (3) and the grouting anchor (4) as the diameter bone (2);

[0045] Among them, the side of the grouting anchor rod (4) is installed with a spreader plate (8), and the end of the spreader plate (8) is equipped with a rotating shaft (13), and the spreader plate (8) passes through the rotating shaft (13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com