Construction method for preventing drilling and hole spraying in drilling construction process of extremely soft coal seam

A construction method and soft coal seam technology, which is applied in earthwork drilling, gas discharge, special data processing applications, etc., can solve the problems of endangering the personal safety of construction personnel, being unable to stabilize the borehole wall, and prone to spray holes, etc. , to achieve the effect of facilitating gas extraction and saving solidified materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below.

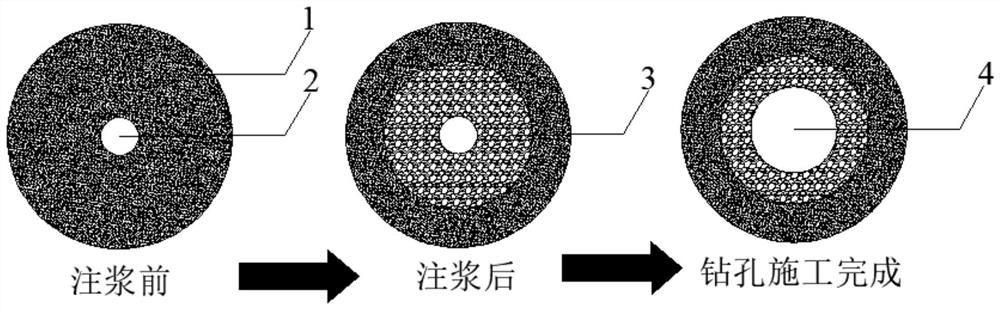

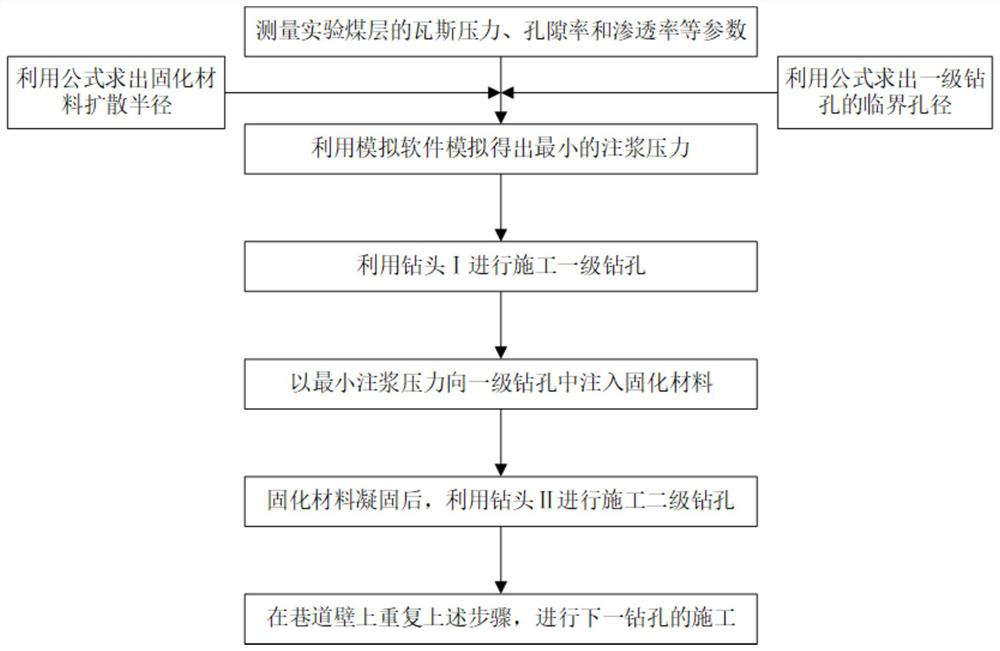

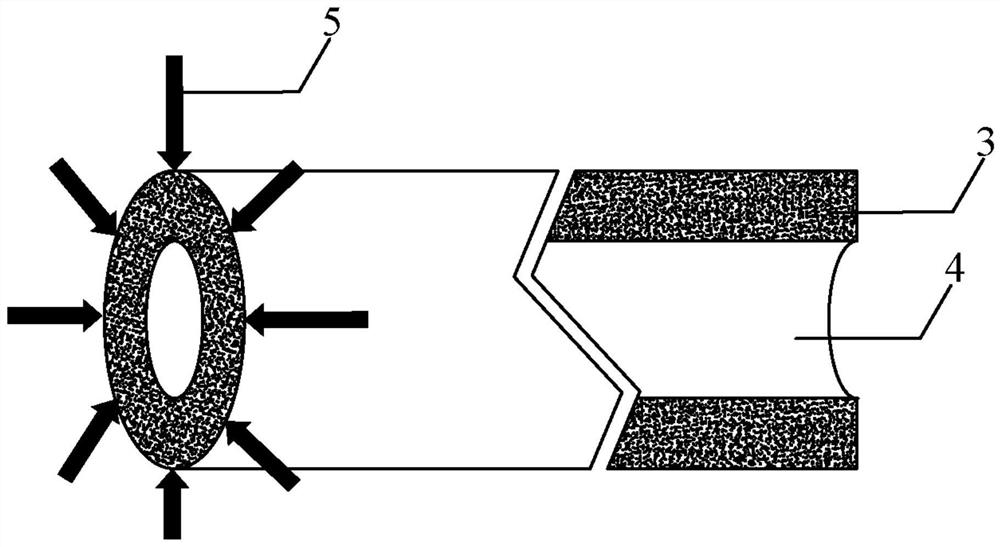

[0043] Such as Figure 1 to Figure 3 Shown, concrete steps of the present invention are:

[0044] A. The parameter data of the coal seam are obtained after measuring and calculating the coal seam required for construction by known methods, and the parameter data includes the elastic modulus of the coal seam, the cohesive force of the coal seam, the ground stress of the coal seam, the internal friction angle of the coal seam, the tensile strength of the coal seam, and the coal seam Density, coal seam gas pressure permeability and coal seam porosity;

[0045] B. Select a known solidified material, measure its density and viscosity, then combine the measured data with the parameter data obtained in step A. The specific data are shown in Table 1. Use existing simulation software to establish a model for injecting solidified material into the coal seam , and then calculate the diffusion radius R of the solidified mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com