TBCC air inlet adjusting mechanism design method based on electric sliding door principle

A design method and a technology for adjusting mechanisms, which are applied to mechanical equipment, jet propulsion devices, gas turbine devices, etc., can solve problems such as large torque and blocking the airflow of bronchial vents, so as to improve sports performance and efficiency and reduce negative effects , Improve the effect of airtight characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

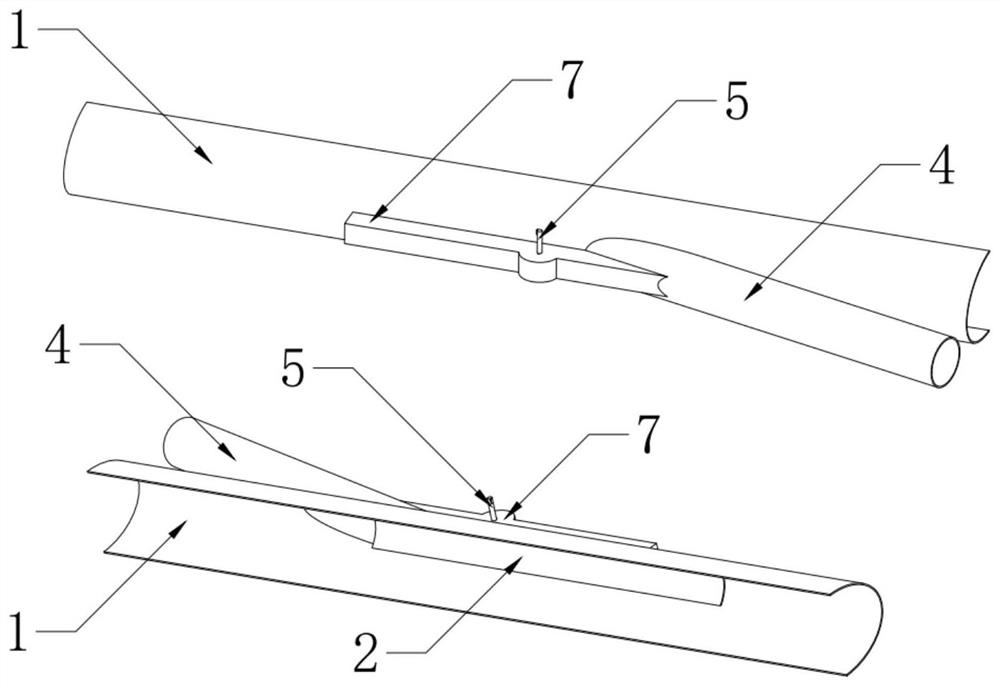

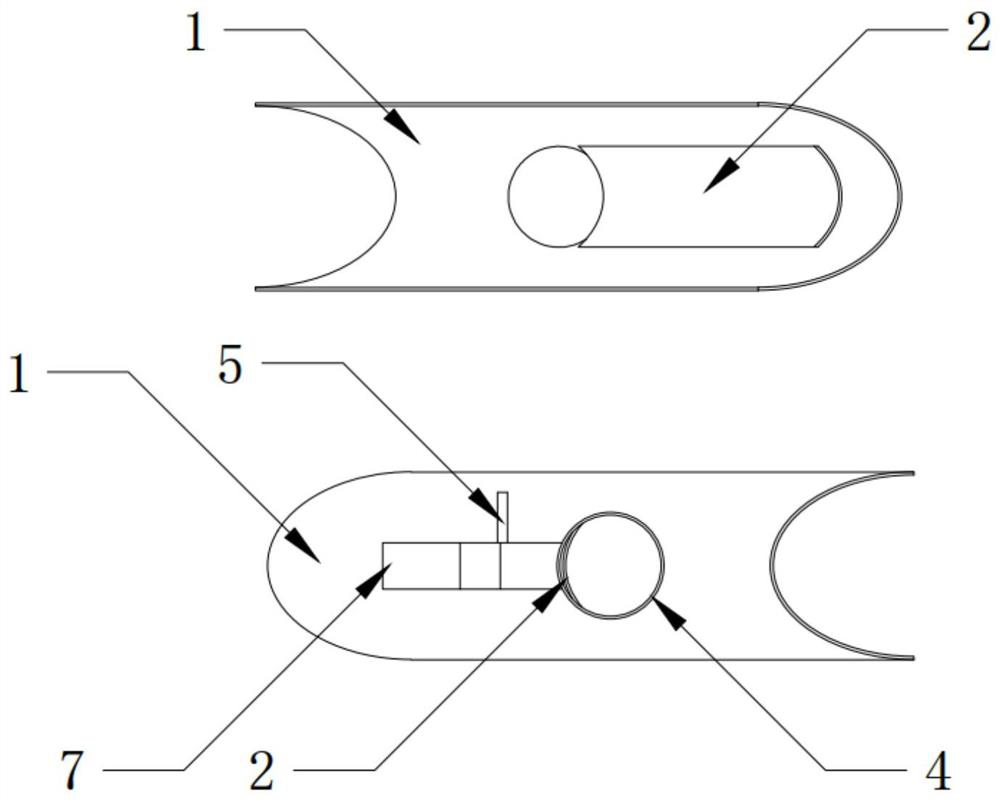

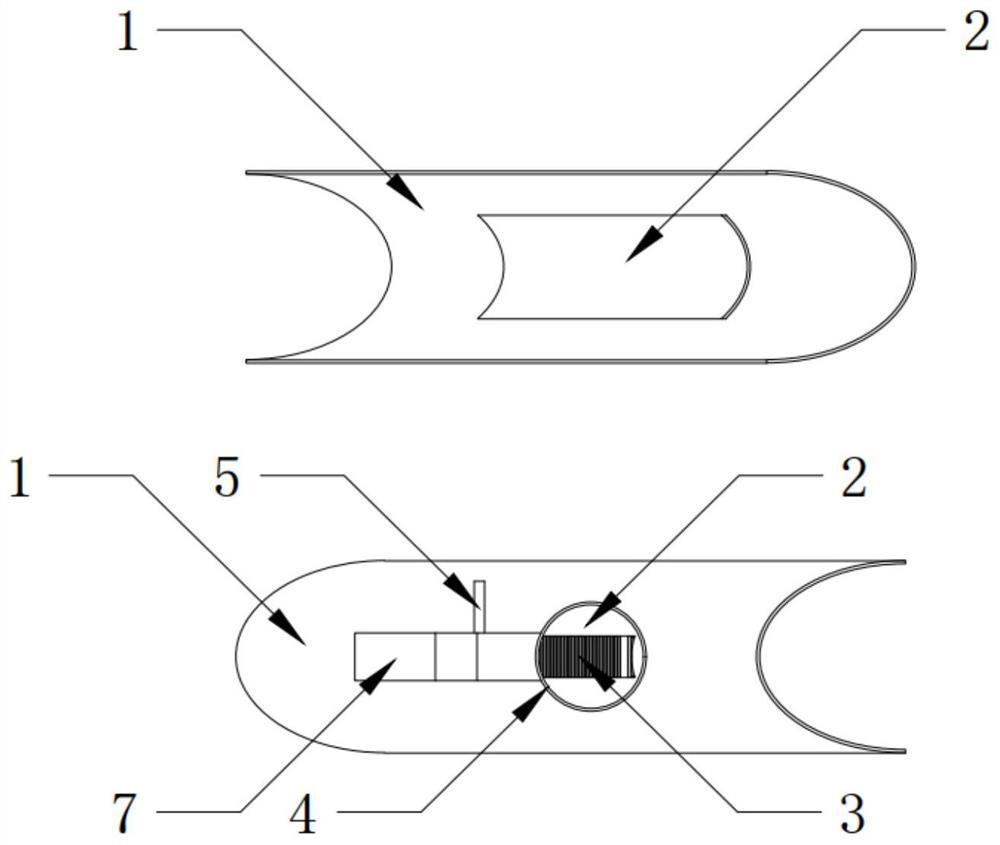

[0024]The invention is further described below with reference to the specific embodiments.

[0025]The present invention provides a TBCC inlet adjustment mechanism based on electric push-pull door principles, in order to make the invention, the embodiments of the present invention will be described in detail. It should be understood that the specific examples described herein are intended to explain the present invention, but is not intended to limit the invention.

[0026]The invention includes the following steps:

[0027]1) Implementing the door body translation in the motion process, when designing the door and the main airway outer wall, the translational movement rail of the door body is designed, so that when the gear rack transmission mechanism is activated by the motor, the drive doors along the guide rail Translate to the specified position;

[0028]2) Officiency of the venting characteristics of the vent when closed; the confirmation of the closed characteristics of the vent when clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com