A high-precision optical lens processing technology and its coating device

A technology of optical lenses and processing technology, applied in optics, optical components, installation, etc., can solve the problems of long time-consuming and low production efficiency of optical lenses, save time, reduce the possibility of direct contact, and reduce the possibility of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

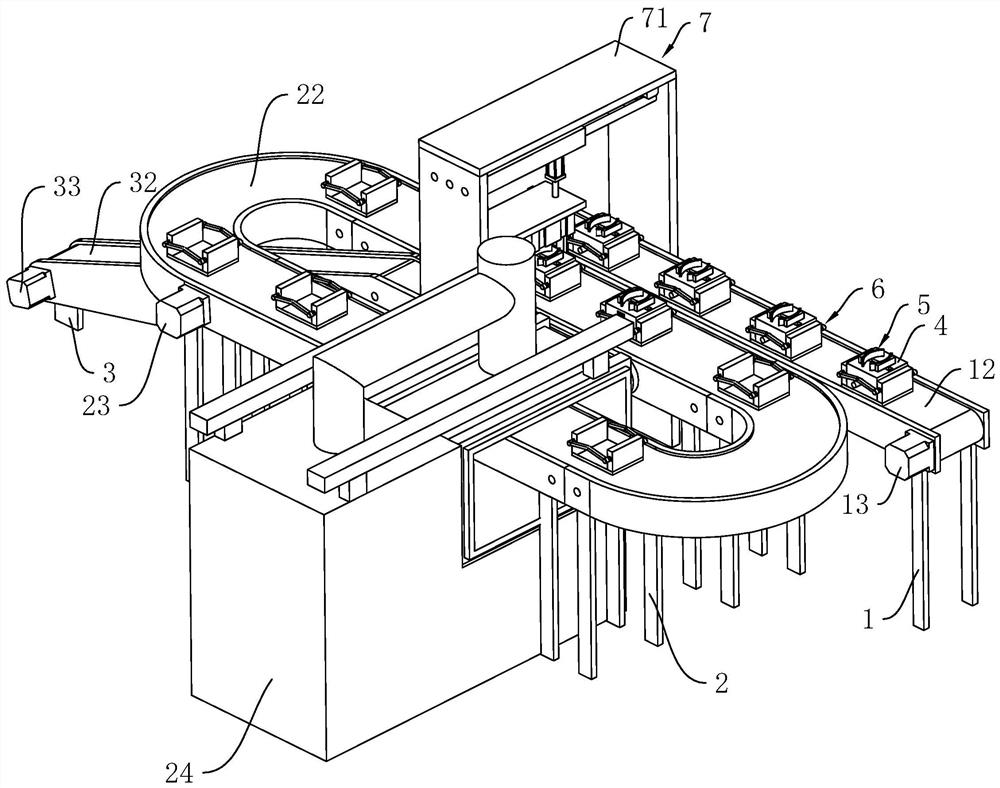

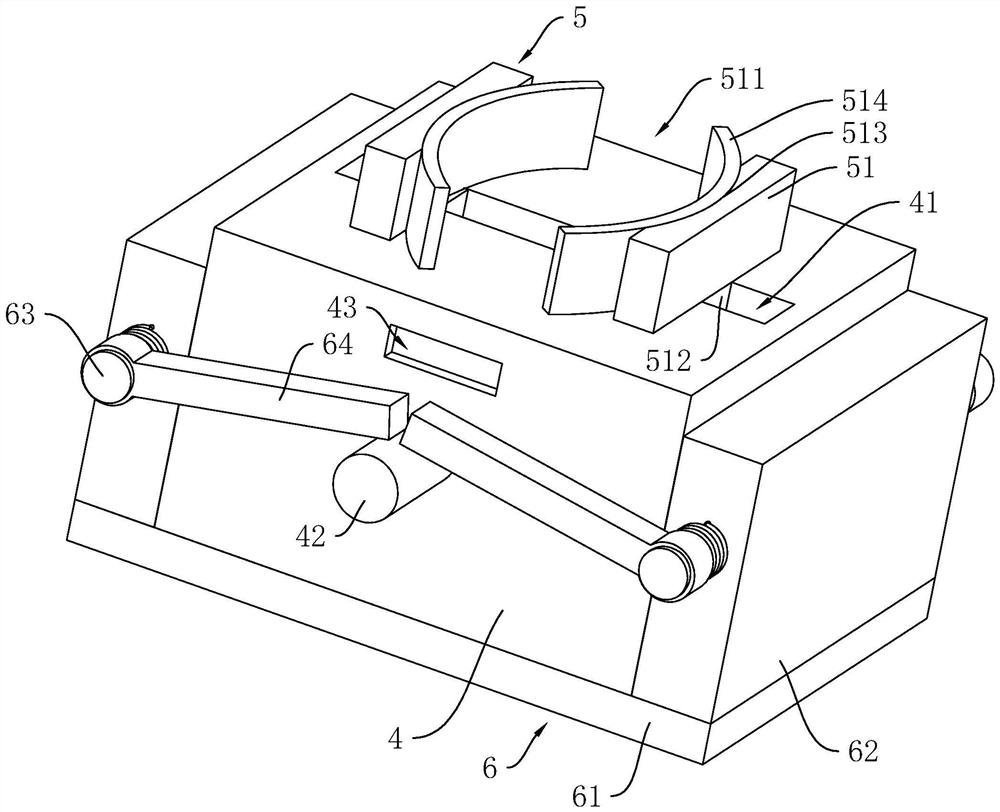

[0049] Attached to the following Figure 1-6 This application will be described in further detail.

[0050] The embodiments of the present application disclose a high-precision optical lens processing technology and a coating device thereof.

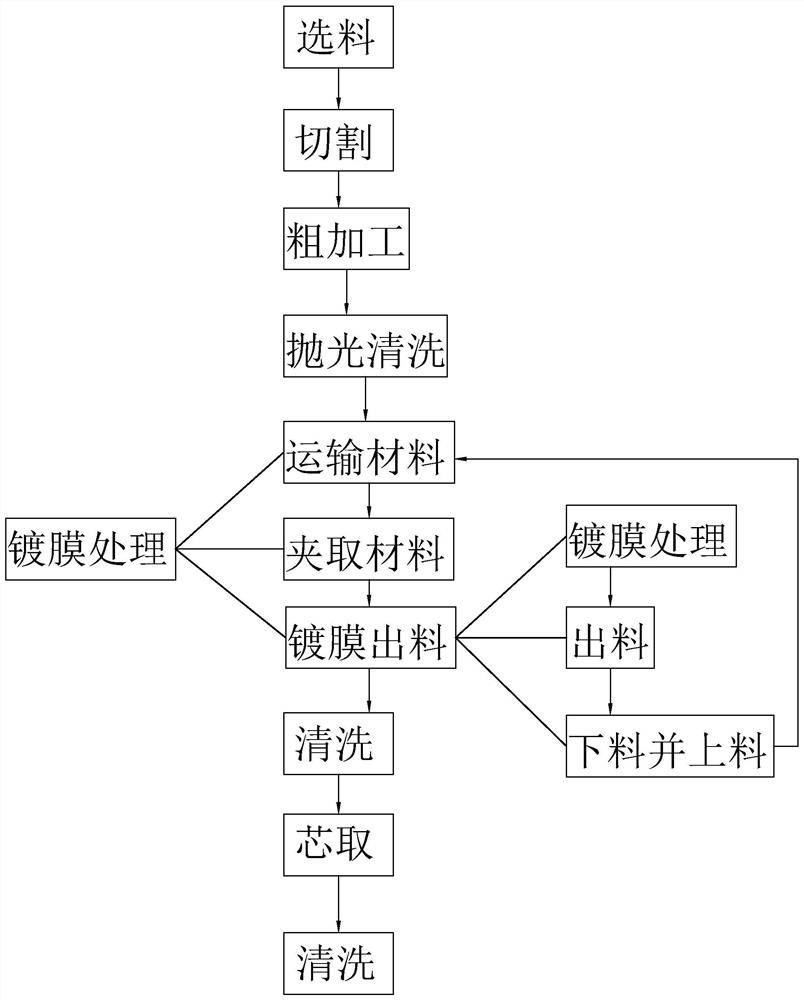

[0051] refer to figure 1 , a high-precision optical lens processing technology includes the following steps:

[0052] S1, material selection: According to the production requirements, select the processing materials that meet the requirements, and prepare to start production and processing;

[0053] S2, cutting: transport the material selected in S1 to the CNC for cutting, and cut the material according to the size requirements of the drawing, so as to produce blanks in batches;

[0054] S3, rough machining: rough machining the blanks that have completed the steps in S2 in order to polish the burrs on their surfaces to make them meet the requirements of polishing production;

[0055] S4, polishing and cleaning: use a polishing machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com