Iron inserting positioning device

A positioning device and iron insertion technology, which is used in workpiece clamping devices, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of unusable, unusable, and inability to position the iron insertion, so as to improve production efficiency. , easy to carry and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

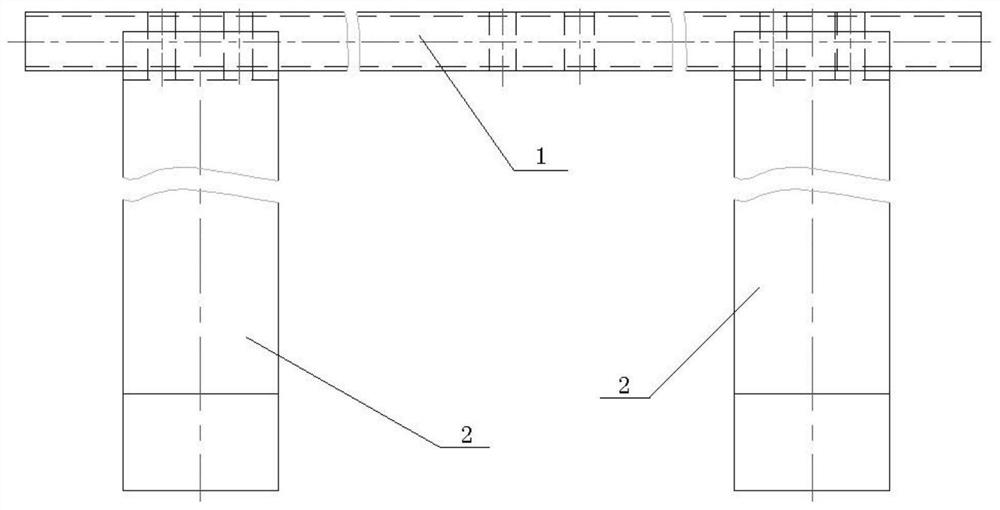

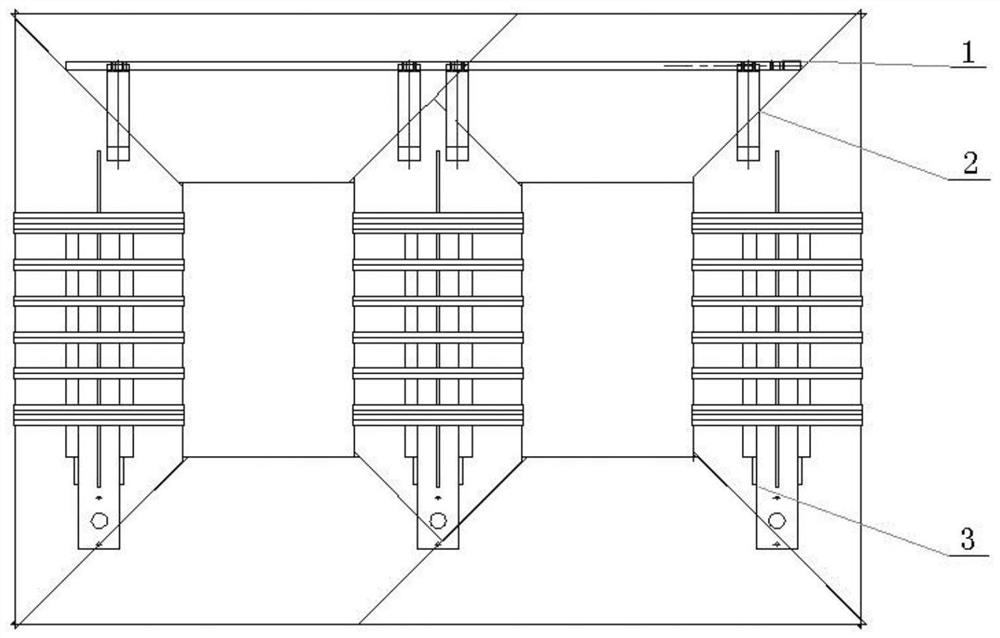

[0021] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the present invention. A positioning device for inserting iron, comprising: a positioning beam 1 whose length can be adjusted, and two or more auxiliary boards 2 whose height can be adjusted, and the positioning beam 1 is vertically fixedly connected with the auxiliary boards 2 . The positioning beam 1 and the auxiliary inserting plate 2 are respectively provided with corresponding fixing holes, and the positioning beam 1 and the auxiliary inserting plate 2 are fixed into one body after the bolts pass through the fixing holes.

[0022] The positioning beam 1 is preferably a square tube structure made of stainless steel and blackened carbon steel. The positioning beam 1 is composed of a plurality of short square tubes of different lengths through a bolt structure, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com