Rice hull spreading device for agricultural planting

A rice husk, spreading technology, applied in application, plant protection, plant protection cover, etc., to prevent clogging, prevent waste, and improve spreading efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

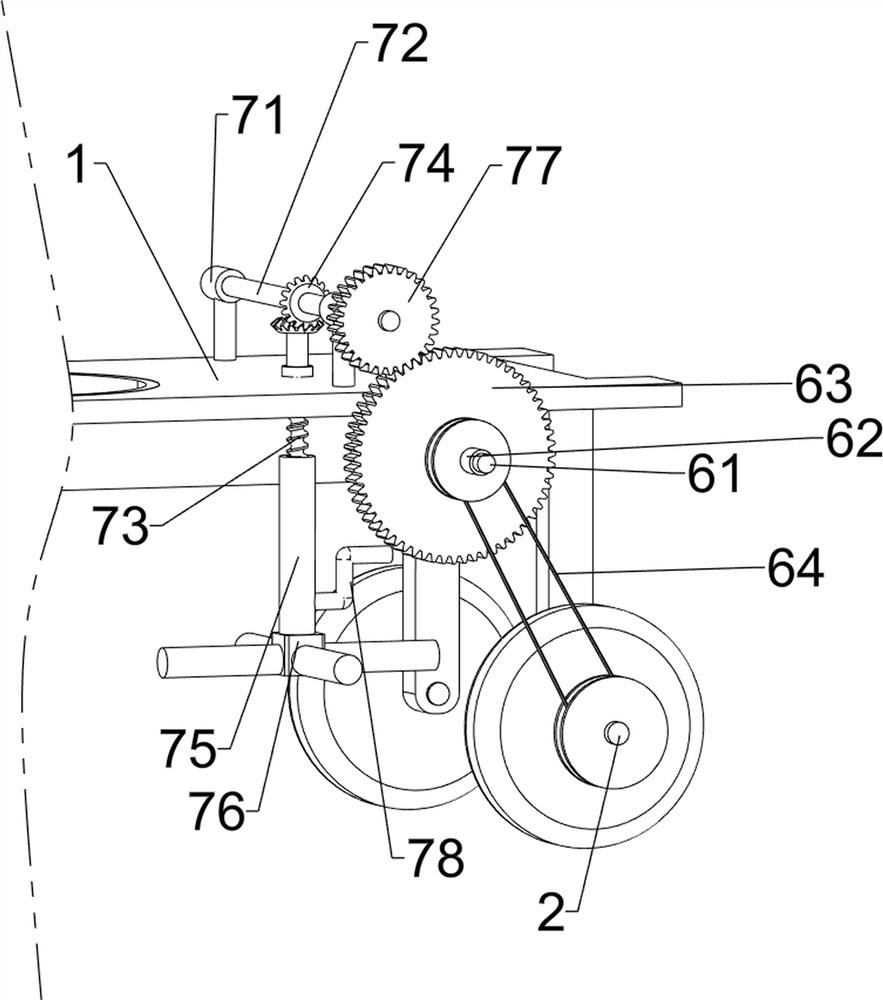

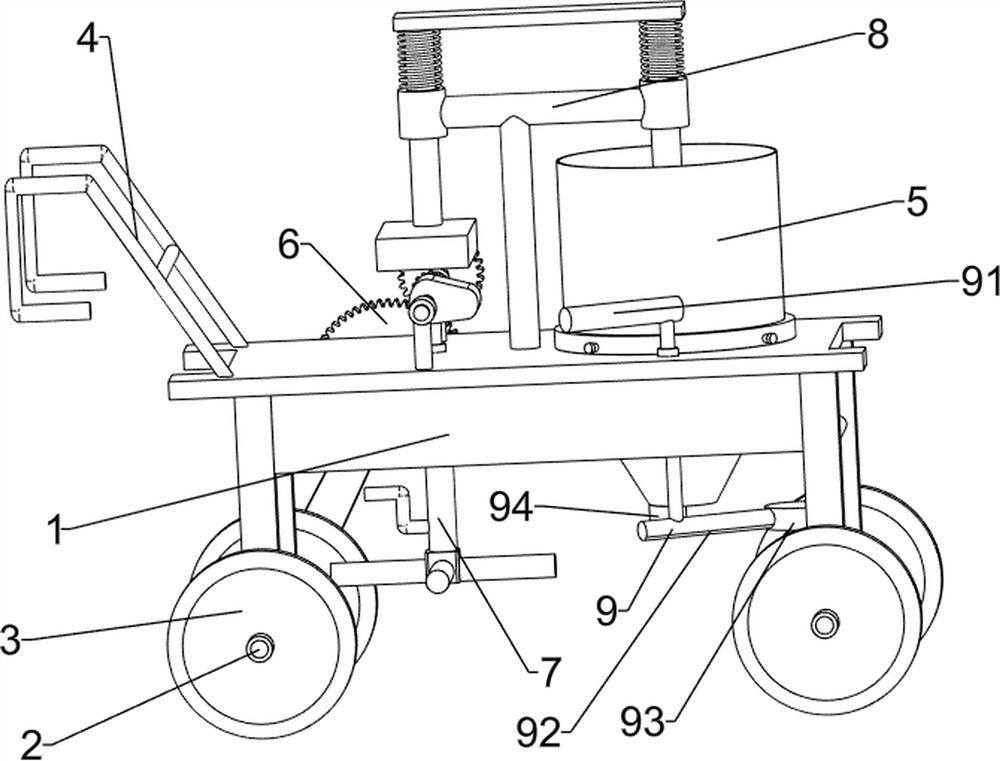

[0023] A rice husk spreading device for agricultural planting, such as Figure 1-2 Shown, comprise vehicle frame 1, wheel axle 2, wheel 3, push handle 4, blanking drum 5, drive mechanism 6 and leveling mechanism 7, the bottom of vehicle frame 1 left and right sides is all front and rear symmetrical rotary connections with two A wheel shaft 2, the wheel shaft 2 is connected with a wheel 3, the left side of the top of the frame 1 is connected with a push handle 4, the right side of the top of the frame 1 is connected with a blanking drum 5, and there are two symmetrical openings at the bottom of the blanking drum 5. A discharge port, a driving mechanism 6 and a leveling mechanism 7 are respectively installed on the vehicle frame 1, and the driving mechanism 6 and the leveling mechanism 7 are connected in transmission.

[0024] The drive mechanism 6 includes a fixed rod 61, a first rotating shaft 62, a first full gear 63 and a belt drive assembly 64. The upper rear side of the ve...

Embodiment 2

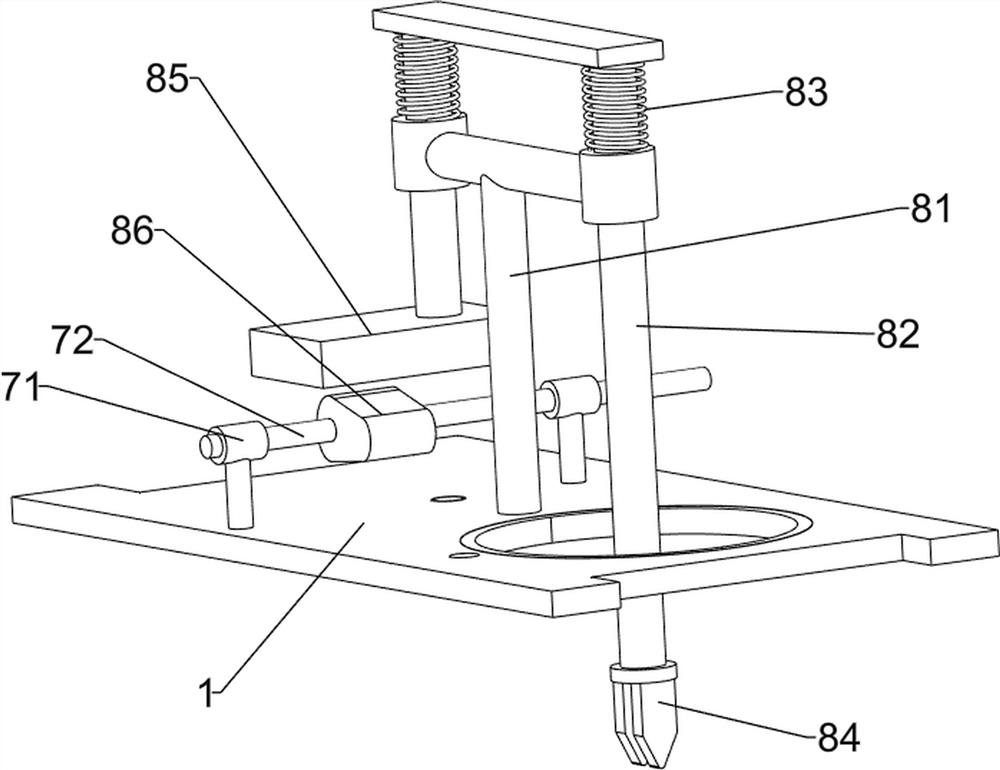

[0028] On the basis of Example 1, such as figure 1 with image 3 Shown, also comprise dredging mechanism 8, and dredging mechanism 8 comprises support 81, connecting frame 82, spring 83, poking block 84, movable plate 85 and cam 86, and vehicle frame 1 top middle is connected with support 81, slides on support 81 There are two springs 83 connected between the connecting frame 82 and the bracket 81, and two poking blocks 84 are connected to the bottom of the right side of the connecting frame 82, and the poking blocks 84 cooperate with the discharge port, and the left side of the connecting frame 82 A movable plate 85 is connected to the bottom, and a cam 86 is connected to the front of the second rotating shaft 72 , and the cam 86 contacts and cooperates with the movable plate 85 .

[0029] The rotation of the second rotating shaft 72 drives the cam 86 to rotate. When the cam 86 rotates to the point where the longer end contacts the movable plate 85, the rotation of the cam 8...

Embodiment 3

[0031] On the basis of Example 2, such as figure 1 Shown, also comprise retaining mechanism 9, retaining mechanism 9 comprises rotating handle 91, connecting rod 92, blocking block 93 and baffle plate 94, and vehicle frame 1 top right front side rotational type is connected with rotating handle 91, and rotating handle 91 The bottom end is connected with a connecting rod 92, and the connecting rod 92 is connected with a blocking block 93. The blocking block 93 cooperates with the blanking drum 5, and the bottom left side of the blanking drum 5 is connected with a baffle plate 94, and the baffle plate 94 is connected with the blocking block 93. Cooperate.

[0032]When the device needs to turn to the blanking without the blanking drum 5, the rotating handle 91 can be rotated manually, and the rotating handle 91 can be rotated through the connecting rod 92 to rotate the blocking block 93 to the bottom of the blanking drum 5, thereby The discharge opening on the blanking drum 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com