Full-automatic dung cleaning device for intelligently driving dairy cows

A fully automatic, dairy cow technology, applied in the field of breeding equipment, can solve the problems of necrosis, cow tissue infection, hard manure scraper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

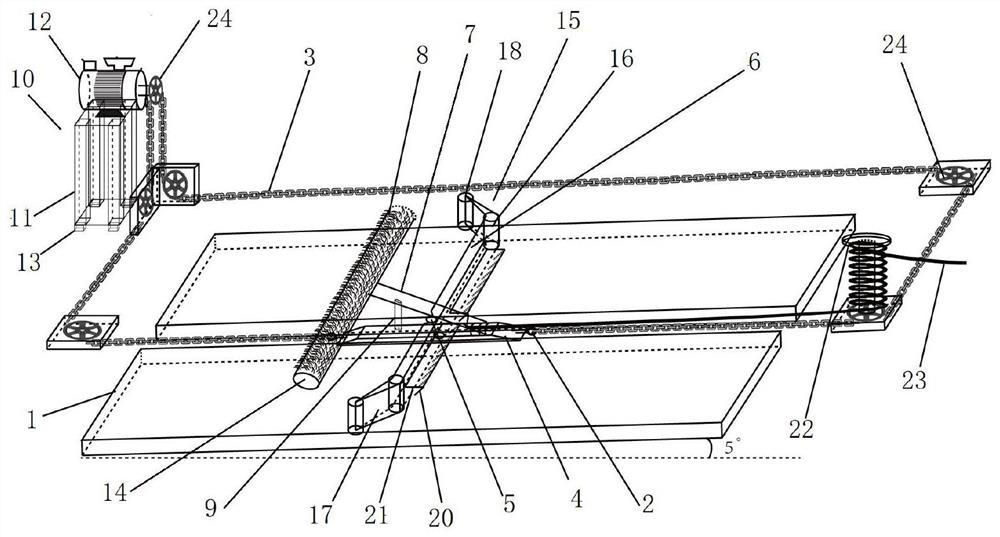

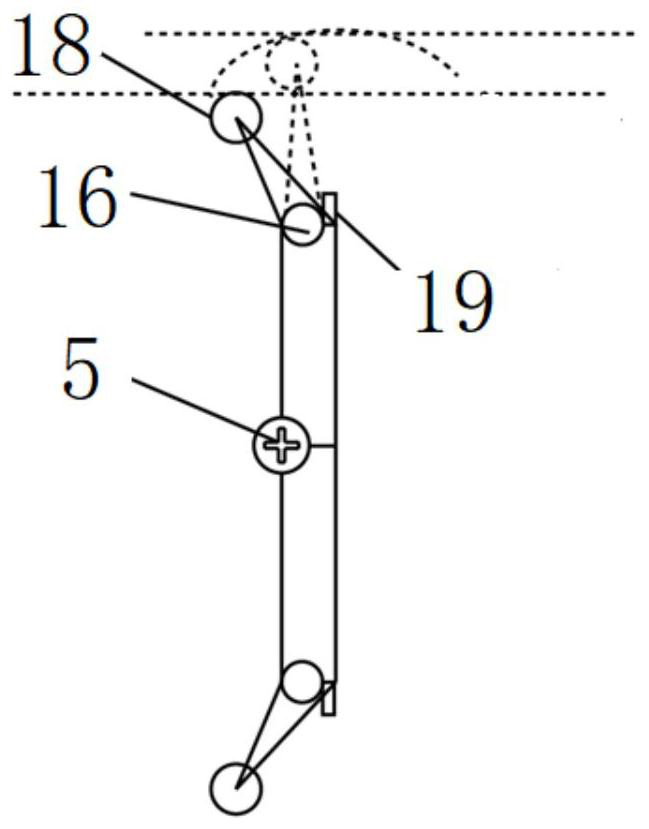

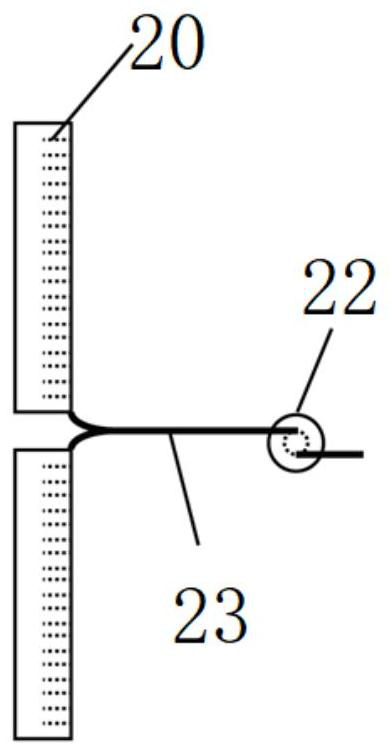

[0028]Seefigure 1 To the fully automatic tuition device that realizes the smart drum of cow, the bottom plate 1 is provided, and the central axis position of the bottom plate 1 is provided with a conveyed belt card slot 2, and the conveyor belt card groove 2 is provided with a conveyor belt 3, and the transmission belt 3 A scraper carrier base 4 is provided, and a scraper support shaft 5 is provided on the strip support shaft 5, and the squeegeeboard support shaft 5 is provided. 4 There is also a cow driven by a cow, the dairy drive, including a push rod 7, hinged with the scraper 8, and the other end of the push rod 7 is provided with a cross-axle 14. A massage roller 8 is rotated along the transversible shaft 14, and the slider 9 is also provided on the top of the ridge 9, and the tape 3 is connected to the push rod 7; The drive device 10 is connected, the drive device 10 includes a motor frame 11 and a motor 12 on the motor frame 11, and the electrical frame 11 is provided with a...

Embodiment 2

[0031]SeeFigure 6The fully automatic cleaned device that realizes the smart drum of cows, including the bottom plate 1, and the central axis position of the bottom plate 1 is provided with a conveyed belt card slot 2, and the conveyor belt card groove 2 is provided with a conveyor belt 3, the transmission belt 3 A scraper carrier base 4 is provided, and a scraper support shaft 5 is provided on the strip support shaft 5, and the squeegeeboard support shaft 5 is provided. 4 There is also a cow driven by a cow, the dairy drive, including a push rod 7, hinged with the scraper 8, and the other end of the push rod 7 is provided with a cross-axle 14. A massage roller 8 is rotated along the transversible shaft 14, and the slider 9 is also provided on the top of the ridge 9, and the tape 3 is connected to the push rod 7; The drive device 10 is connected, the drive device 10 includes a motor frame 11 and a motor 12 on the motor frame 11, and the electrical frame 11 is provided with a pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com