Tea leaf drying method

A technology of tea leaves, left and right sides, applied in the field of tea drying, can solve the problems that the efficiency of production and processing cannot be improved, the drying effect needs to be further improved, and it is difficult to dry tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

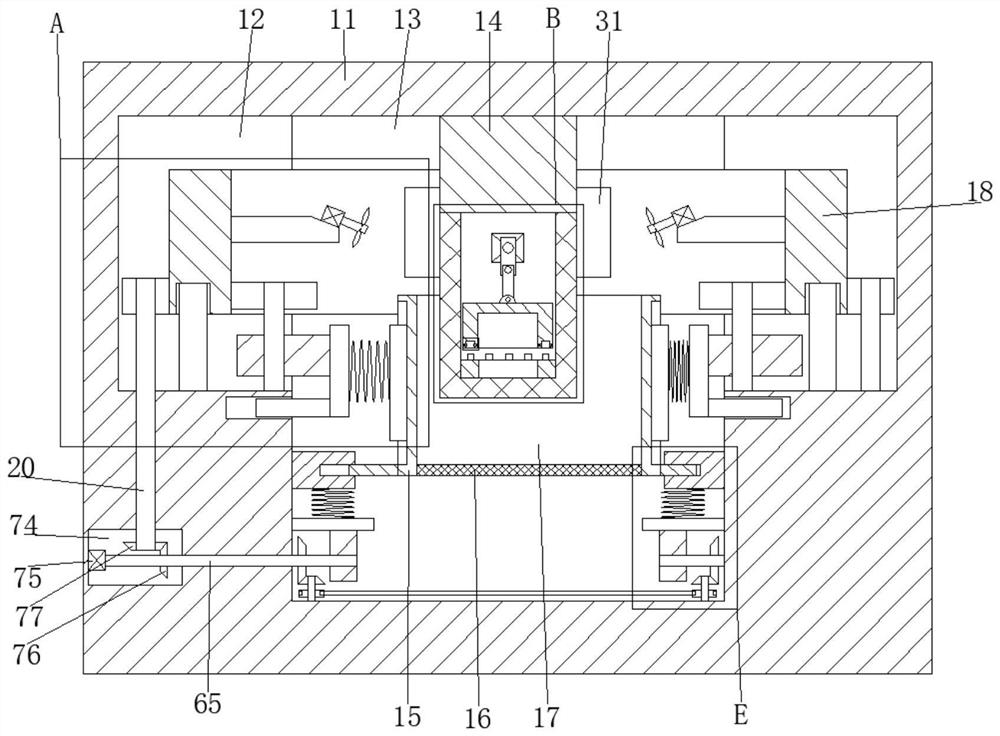

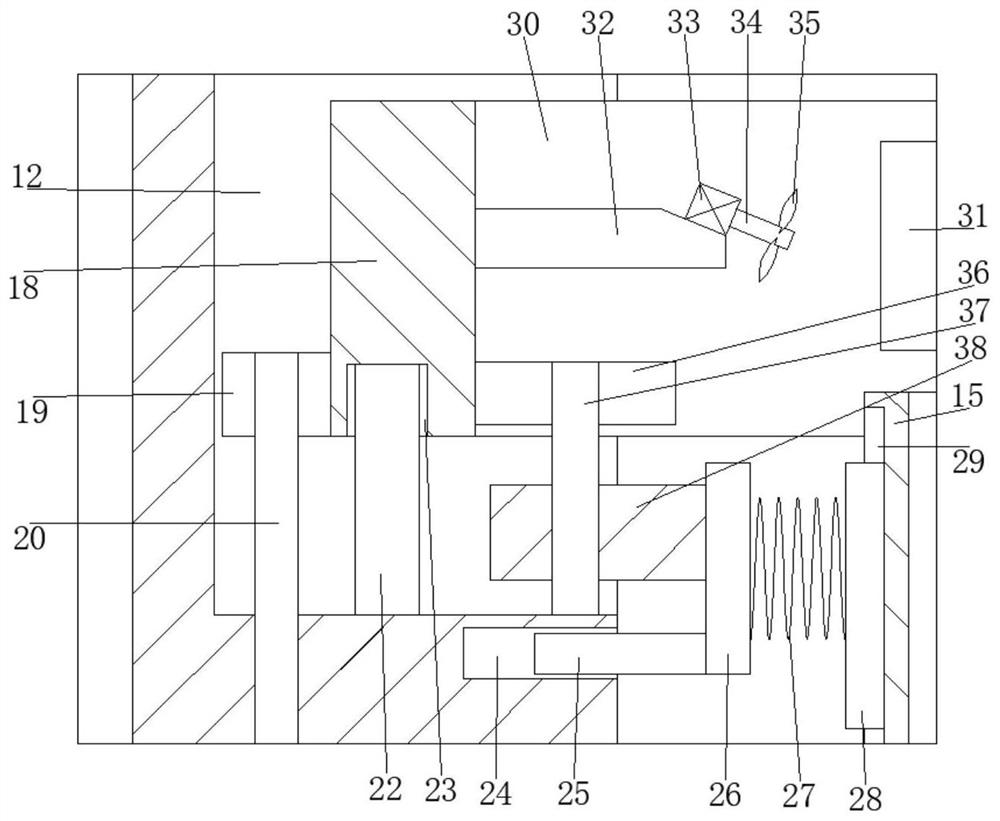

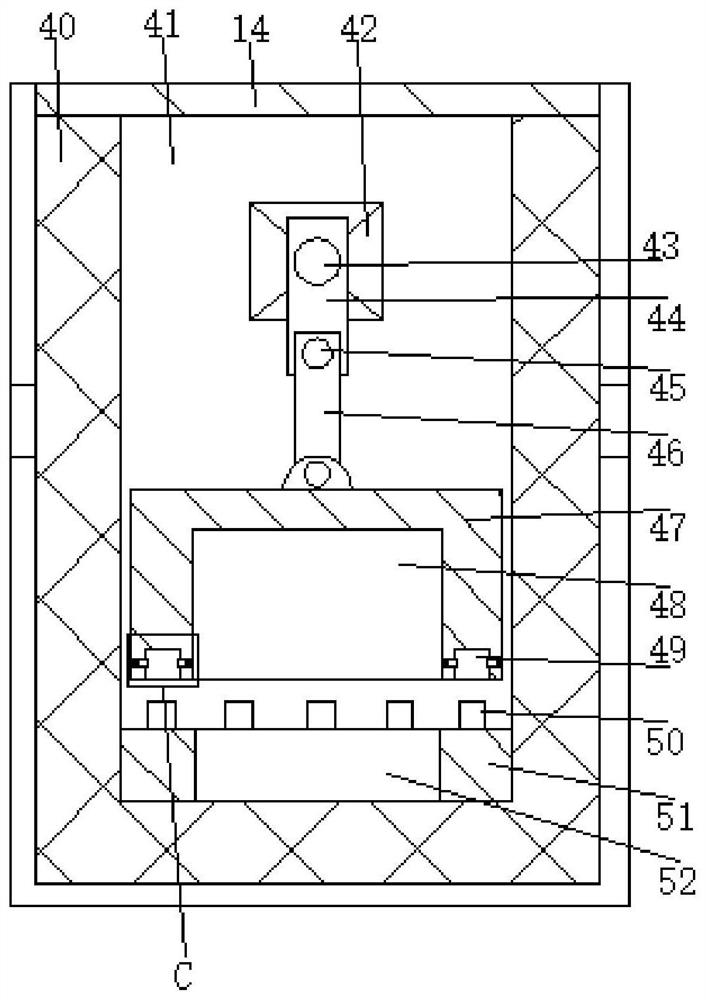

[0028] Such as Figure 1 to Figure 6 As shown, the wrap-around tea drying machine of this embodiment includes a drying box 11, and a drying chamber 13 is arranged inside the drying box 11. The left and right sides of the drying chamber 13 are connected with a symmetrical transmission chamber 12, and the drying The rear wall of the chamber 13 is connected with a placement port 31 communicating with the outside world. The lower walls of the transmission chamber 12 on the left and right sides are fixedly connected with symmetrical support sliding blocks 22. Rotate the ring block 18, and the lower wall of the rotating ring block 18 is connected with an annular guide slip ring cavity 23, and the left and right sides support the slide block 22 to exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com