Printing and dyeing raw material mixing device

A mixing device and raw material technology, which is applied in the field of textile printing and dyeing, can solve the problems of affecting the coloring effect of printing and dyeing, the mixing effect is not very good, and the mixing degree is different, so as to achieve good water gathering effect, good mixing effect and improved strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

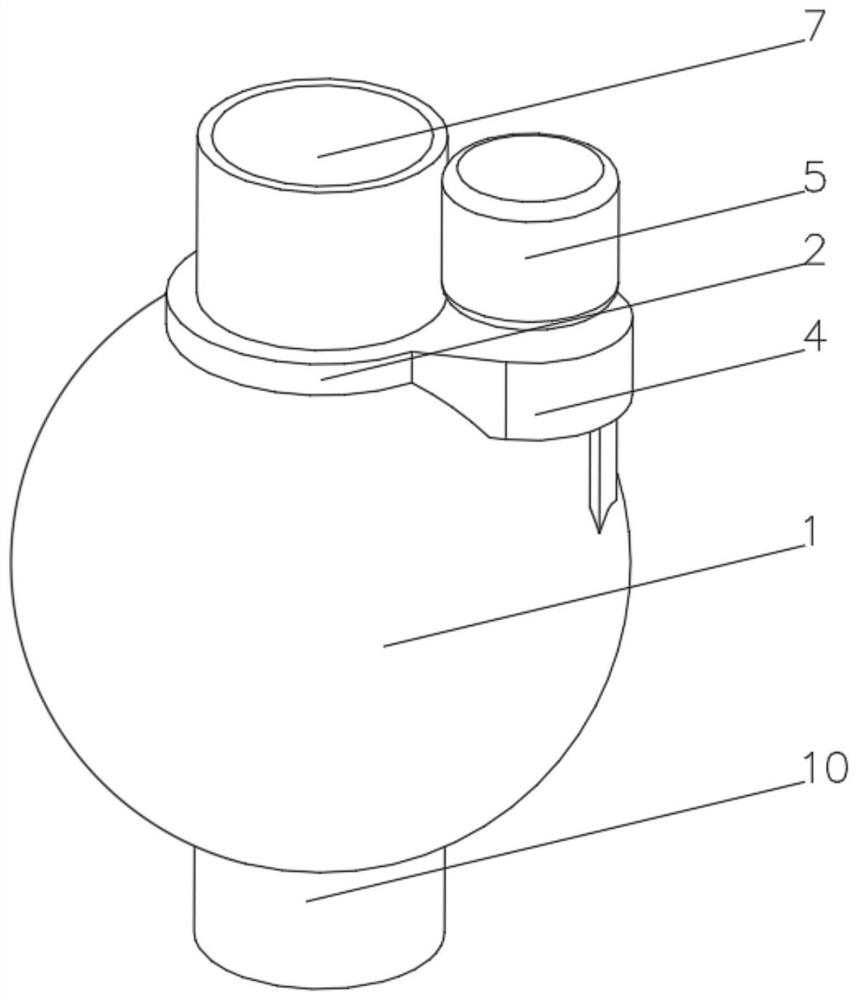

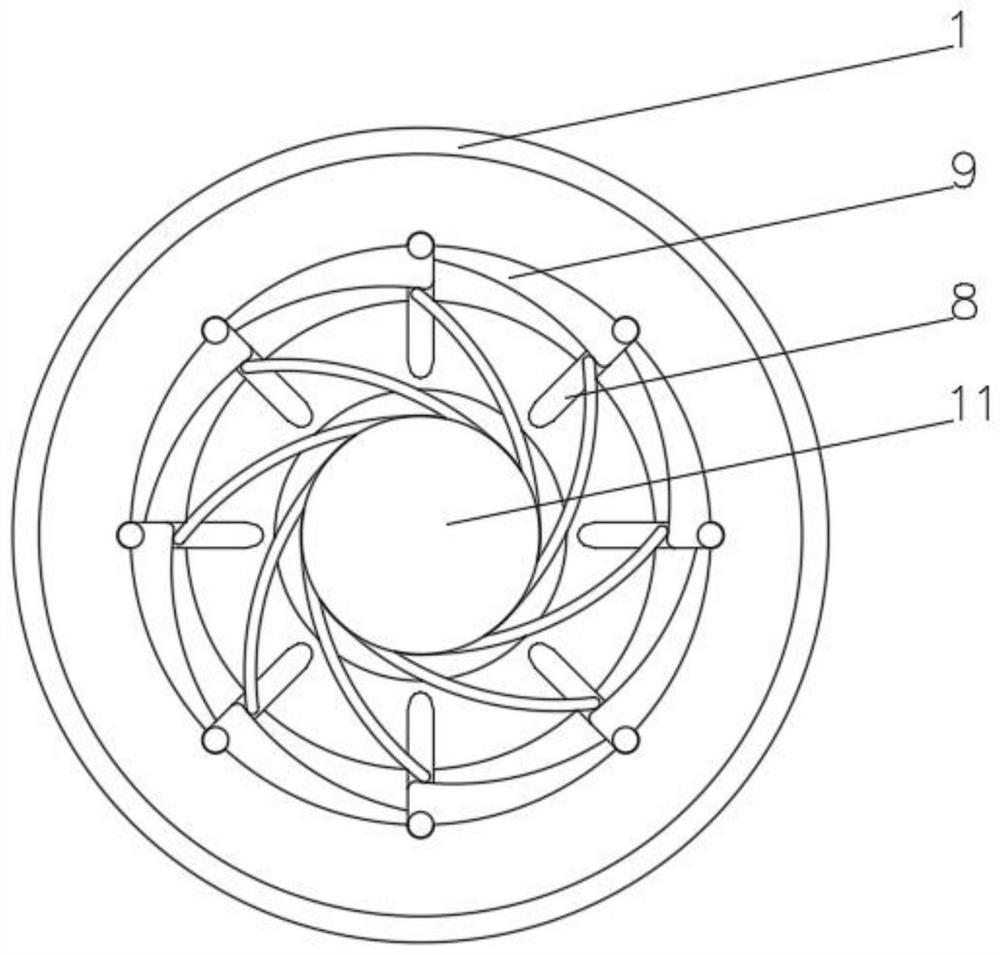

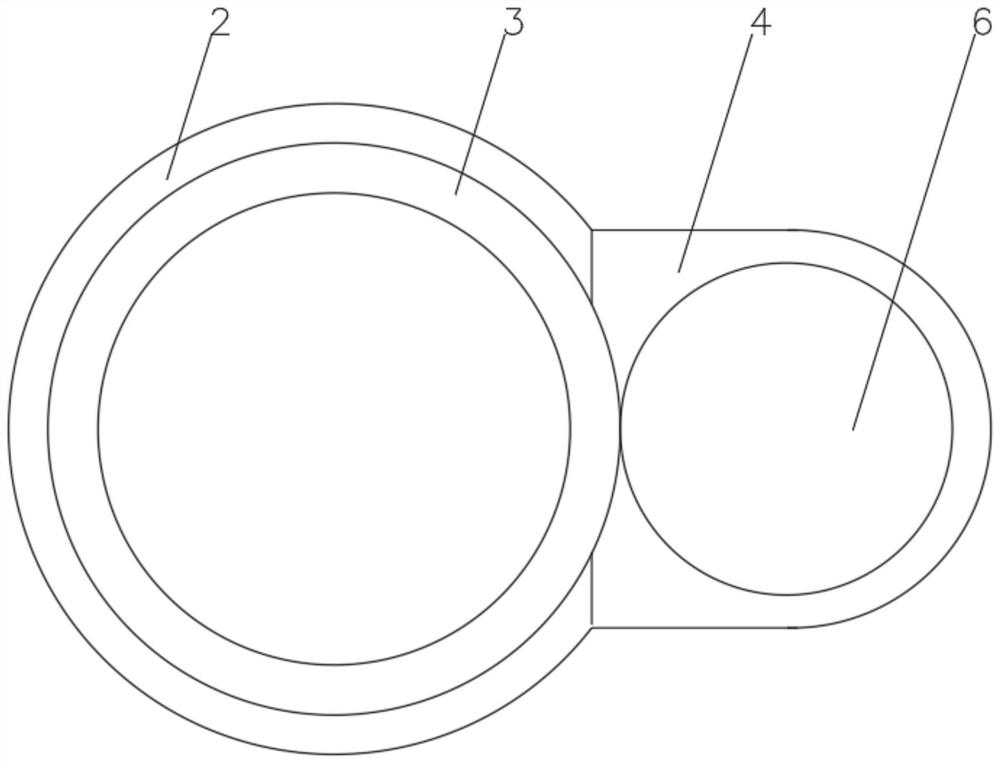

[0034] see Figure 1-6, the present invention provides a technical solution: a printing and dyeing raw material mixing device, including a mixing ball 1, the top of the mixing ball 1 is connected with a rotating seat 2, and the inner wall of the rotating seat 2 is connected with a driving ring gear 3 through bearing rotation, and one side of the rotating seat 2 The drive box 4 is fixedly connected, the top of the drive box 4 is fixedly connected with the drive motor 5, the drive shaft of the drive motor 5 runs through the top of the drive box 4 and extends to the inside of the drive box 4, and the drive shaft of the drive motor 5 is located at one end of the drive box 4 The drive gear 6 is fixedly connected, the top of the rotating seat 2 is connected with the feed pipe 7, the bottom of the drive ring gear 3 is fixedly connected with an arc-shaped stirring rod 8, and the center position of one side of the arc-shaped stirring rod 8 is fixedly connected with a toggle device 9, an...

Embodiment 2

[0037] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: the rolling protection device 93 includes a rolling wheel 931, a buffer groove 932 is opened on the outer side of the rolling wheel 931, and a fixed seat 933 is fixedly connected to the bottom of the inner wall of the buffer groove 932, and the fixed seat 933 The outer side is provided with a mounting groove 934, and the inner wall of the mounting groove 934 is slidingly connected with a rubber ball 935. The buffer groove 932 is a concave limiting groove. The mounting groove 934 is provided with several groups and is evenly distributed on the fixing seat 933. One side of the inner wall of the installation groove 934 extends to the outside of the buffer groove 932. When the arc-shaped toggle plate 112 on the pushing device 11 slides on the toggle device 9, the arc-shaped toggle plate 112 can be supported by the rolling protection device 93 , change sliding into rolling, red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com