Crushing device for household garbage treatment

A technology of domestic waste and crushing device, which is applied in the direction of grain processing and packaging, can solve the problems of poor crushing effect and insignificant cutting effect of domestic waste, and achieves the effect of novel structure, good crushing effect and improving crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

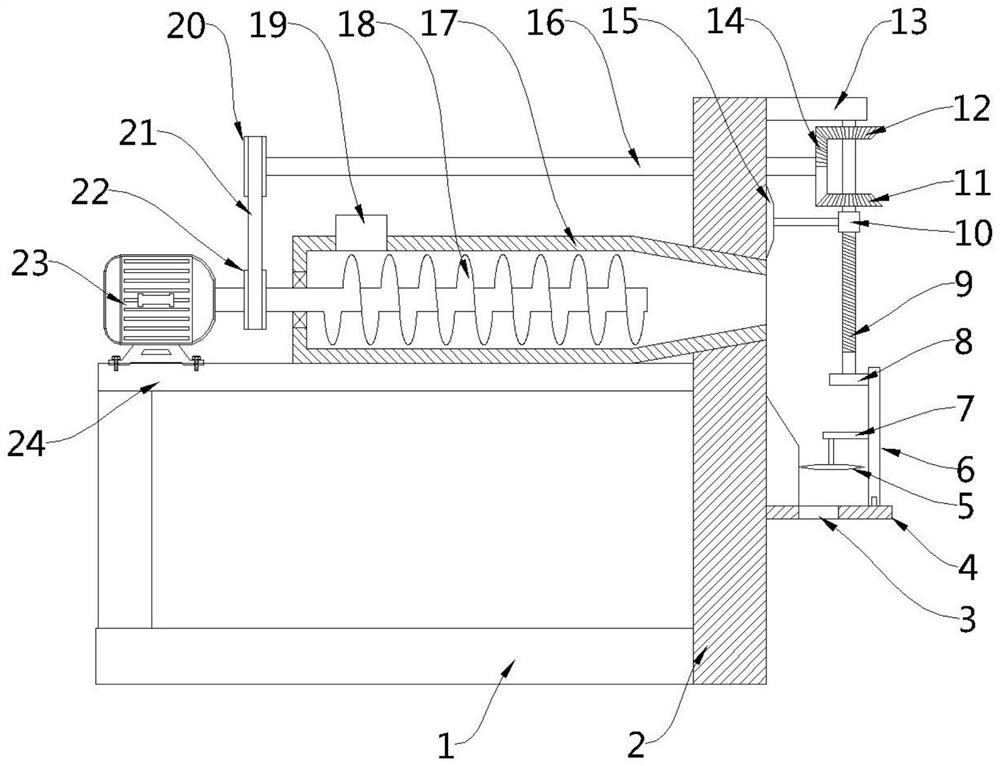

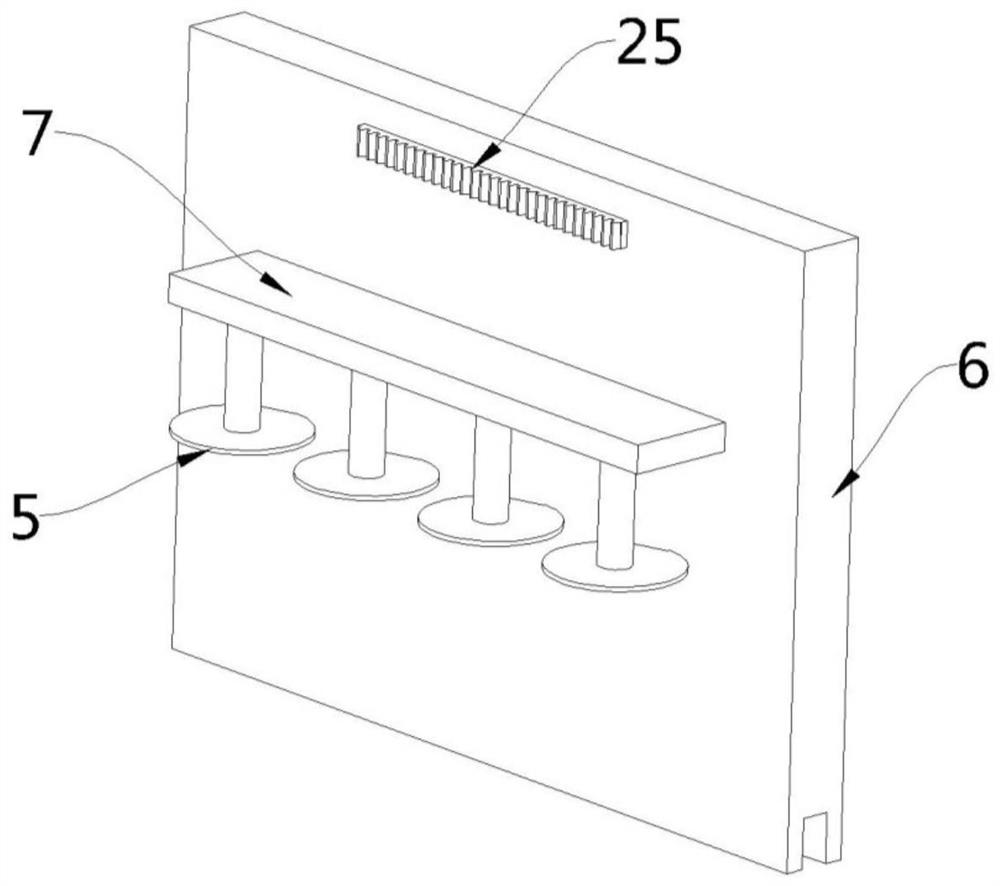

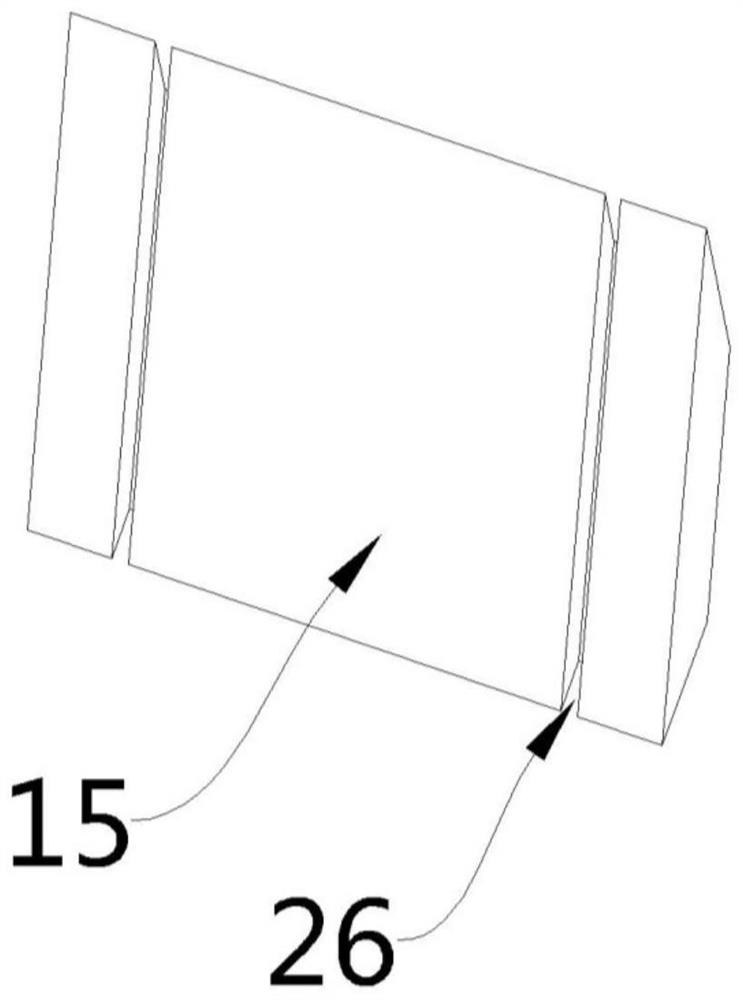

[0023] see Figure 1-3 , this embodiment provides a crushing device for domestic waste treatment, including a base 1 and a vertical plate 2 fixedly arranged on one side of the base 1, a material conveying assembly is fixedly installed on one side of the vertical plate 2, and the vertical plate 2 The other side is provided with a vertical cutting assembly, specifically, the material conveying assembly includes a conveying cylinder 17 and a conveying auger 18 arranged inside the conveying cylinder 17, and the upper part of the conveying cylinder 17 is provided with a feeding port 19. One end of the conveying auger 18 extends to the outside of the material conveying cylinder 17 and is fixedly connected with a motor 23. The conveying auger 18 is also fixedly provided with a first pulley 22. One end of the conveying auger 17 passes through the vertical plate 2 And flush with the side wall of the vertical plate 2; the vertical cutting assembly includes a support top plate 13 fixedly...

Embodiment 2

[0033] see figure 1 , a crushing device for domestic waste treatment. Compared with Embodiment 1, the side wall of the vertical plate 2 in this embodiment is fixedly provided with a mounting plate 24, and the motor 23 and the feeding cylinder 17 are fixedly disposed on the mounting plate 24. Plate 24 upper part.

[0034] The embodiment of the present invention has the advantages of novel structure, convenient use, and good crushing effect. Through the mutual cooperation of the feeding assembly, the vertical cutting assembly and the cross-cutting assembly, the vertical and horizontal double cutting of domestic waste can be realized, thereby improving the efficiency of domestic waste. The degree of crushing and refinement improves the crushing effect of domestic waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com