Automatic cleaning device for textile dye barrel

An automatic cleaning and dye bucket technology, which is applied to cleaning hollow objects, drying gas arrangement, cleaning methods and utensils, etc., can solve the problems of low cleaning efficiency of textile dye buckets, labor and financial resources, etc. The cost of financial resources and the effect of improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

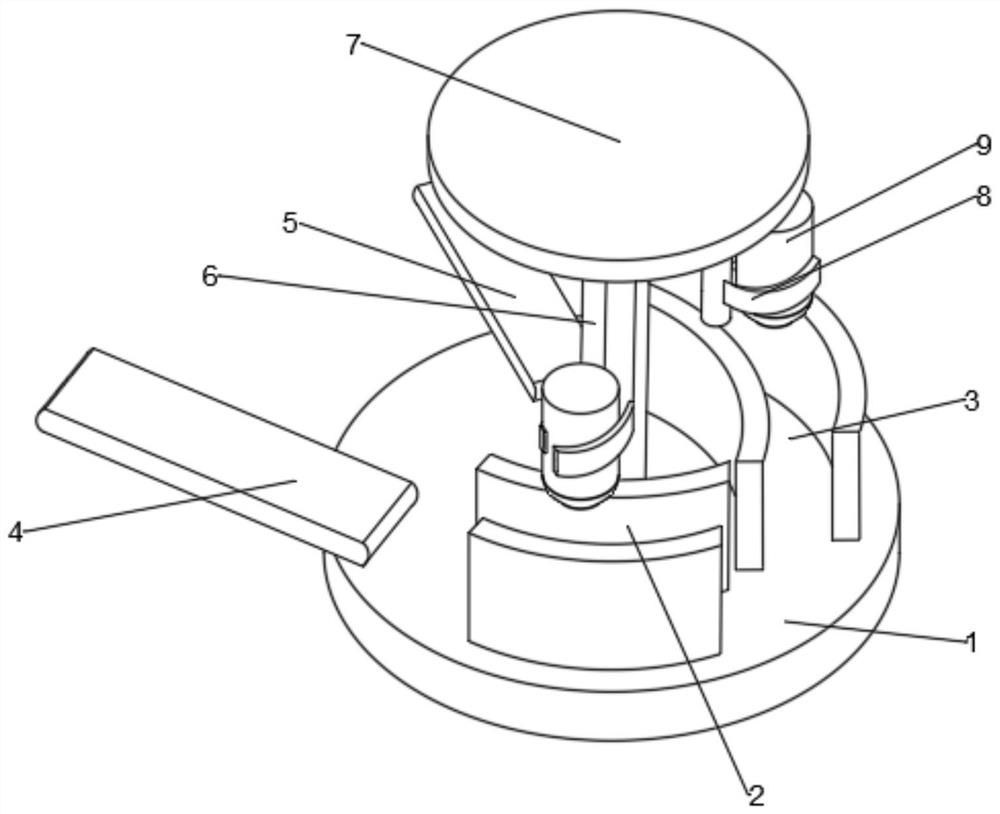

[0028] see Figure 1-7 , in Embodiment 1 of the present invention, an automatic dye barrel cleaning device for textiles, comprising a circular base 1, the upper end of the circular base 1 is sequentially provided with an incoming conveyor belt 4, a cleaning area 2, a drying area 3 and a conveyor belt. Out of the conveyor belt 5, two protective plates 29 are fixedly arranged on the left and right sides of the cleaning area 2 and the drying area 3, and the center of the circular base 1 is provided with a rotating rod 6, and the top end of the rotating rod 6 is fixed An upper top plate 7 is provided, and the lower surface of the upper top plate 7 is evenly fixed with four first telescopic rods 42, and the bottom ends of the first telescopic rods 42 are fixedly provided with a clamping mechanism 8, and the clamping mechanism 8 is clamped and fixed with a dye bucket 9, so that the dye bucket 9 can pass through the cleaning zone 2 and the drying zone 3 in sequence, thereby realizing...

Embodiment 2

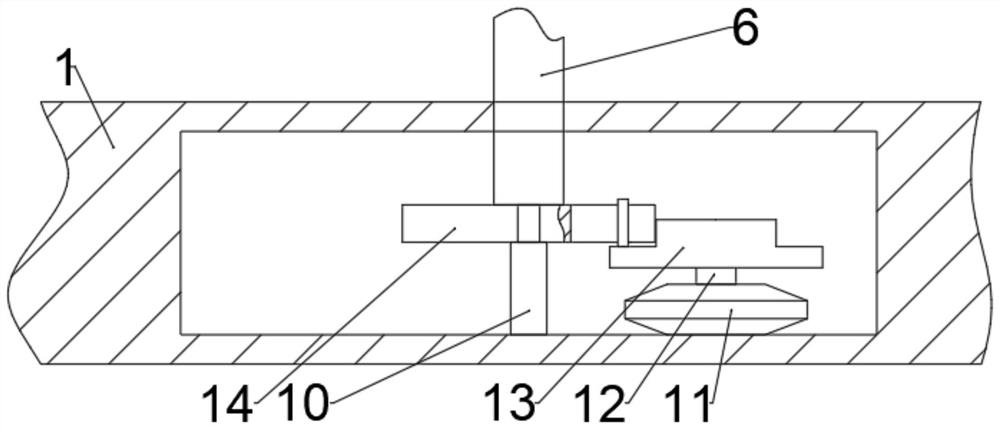

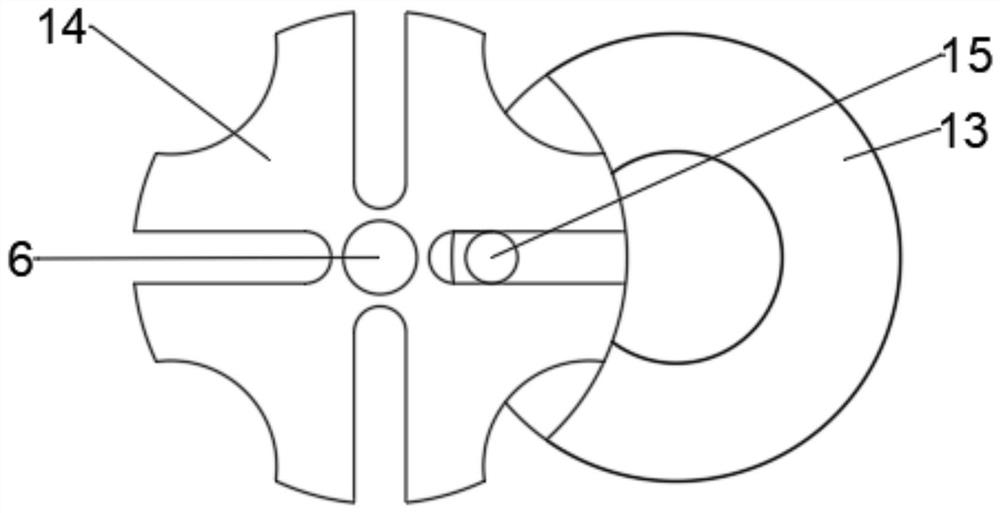

[0030] see Figure 1-7 The main difference between this embodiment 2 and embodiment 1 is that the interior of the circular base 1 below the rotating rod 6 is provided with an intermittent rotating rod 6 mechanism, and the intermittent rotating mechanism includes an intermittent turntable 14, and the intermittent turntable The bottom end of 14 is rotationally connected with the circular base 1 through the connecting rod 10, the lower end of the rotating rod 6 runs through the surface of the circular base 1, and is fixedly connected with the upper surface of the intermittent turntable 14, and the right side of the intermittent turntable 14 is provided with The first motor 11, the bottom end of the first motor 11 is fixedly connected with the circular base 1, the output end of the first motor 11 is fixedly connected with an output shaft 12, and the other end of the output shaft 12 is fixedly connected with a rotating The dial 13, the upper surface of the rotating dial 13 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com