A device and method for preparing a surface gradient structure of pure nickel n6 rods

A surface gradient and pure nickel technology, applied in the direction of metal extrusion dies, etc., can solve the problems of unstable gradient structure of pure nickel N6 rods, large plastic deformation of billet surface materials, high processing costs, etc., and achieve simple structure and improved internal hardness , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

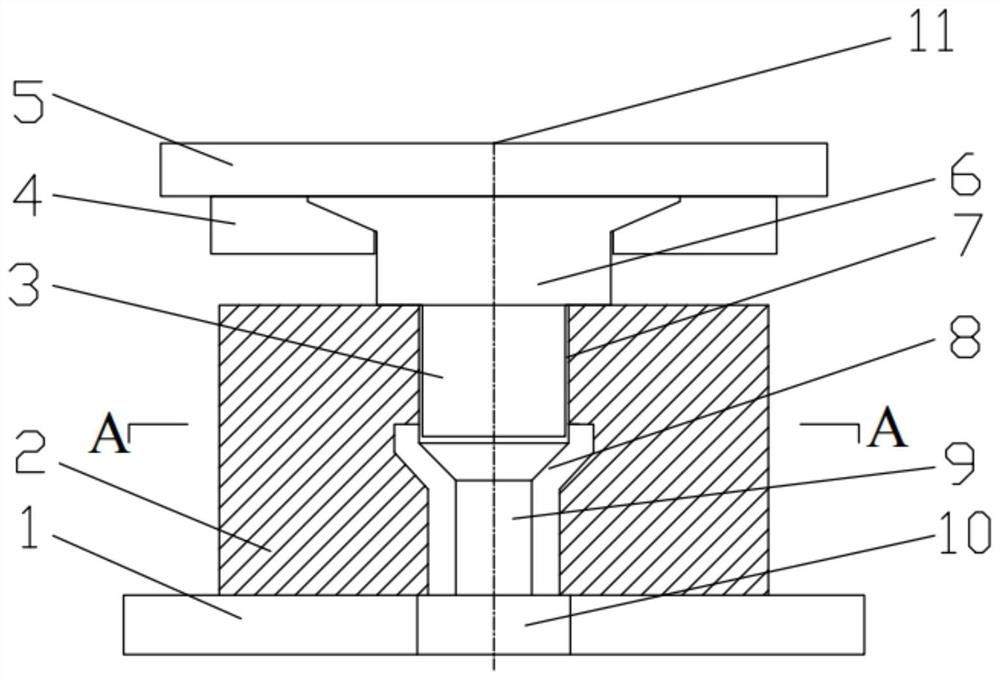

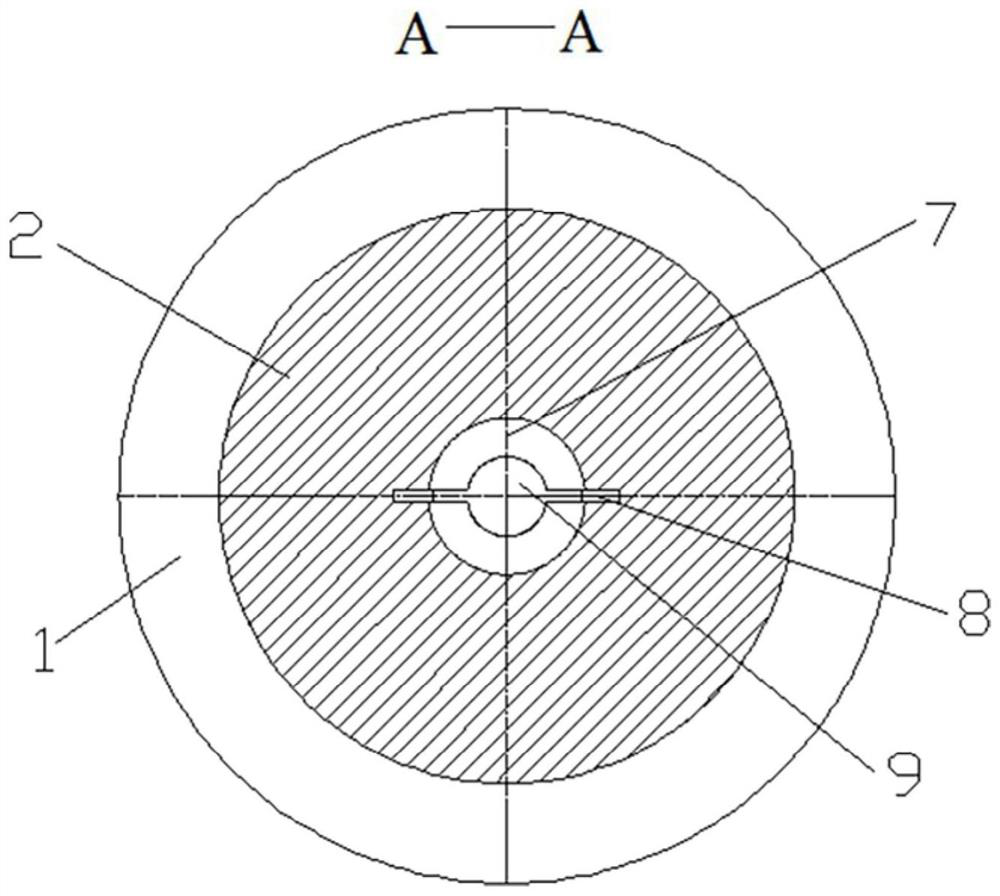

[0026] Present embodiment 1 provides a kind of device that prepares pure nickel N6 rod surface gradient structure, as Figure 1-2 As shown, including the device body 11, the top of the device body 11 is an upper template 5, and the upper template 5 is fixedly connected with a upper mold fixing plate 4, and the upper mold fixing plate 4 is fixedly connected with an upper mold 6, and the lower part of the upper mold 6 is arranged There is an extrusion cylinder 7, and the lower part of the extrusion cylinder 7 is provided with an extrusion channel 9, and the lower part of the extrusion cylinder 7 and both sides of the extrusion channel 9 are provided with two symmetrical grooves 8, and the width of the groove 8 is the width of the extrusion channel 9. 1 / 7 of the diameter, the depth of the groove 8 is 3 / 7 of the diameter of the extrusion channel 9, the discharge channel 10 is arranged below the extrusion channel 9, the bottom of the device body 11 is the fixed plate 1, and the fixe...

Embodiment 2

[0029] Present embodiment 2 provides a kind of device that prepares pure nickel N6 rod surface gradient structure and is identical with embodiment 1, adopts this device to prepare the method for pure nickel N6 rod surface gradient structure, comprises the following steps:

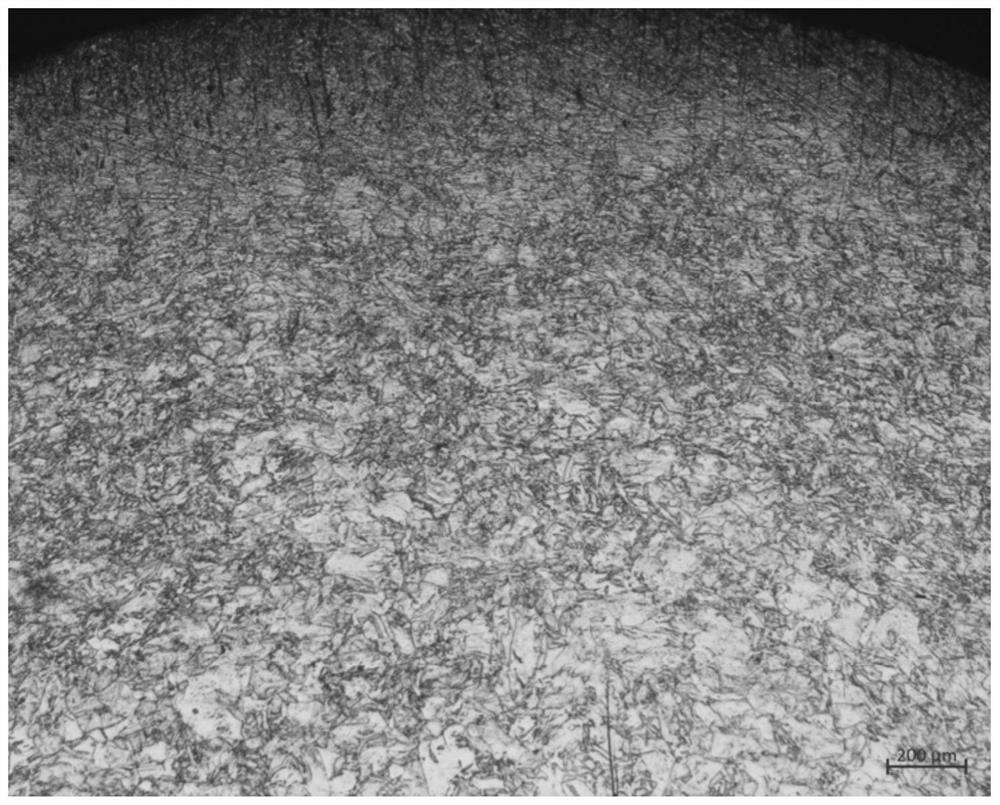

[0030]The pure nickel N6 alloy ingot obtained by vacuum electromagnetic stirring smelting is cut into a cylindrical billet of Φ30mm×15mm by wire electric discharge cutting, and then the pure nickel N6 cylindrical billet is heated to 280°C and kept for 40 After 10 minutes, evenly smear solid graphite lubricant powder on the surface of the cylindrical blank, and simultaneously apply graphite lubricant powder on the surface of the extrusion cylinder 7, the surface of the extrusion channel 9, and the surface of the groove 8, and put the heated cylindrical blank into the extrusion Inside the cylinder 7, the upper die 6 starts to move, and the die 3 exerts pressure on the blank to start extrusion. The extrusion te...

Embodiment 3

[0032] Present embodiment 3 provides a kind of device that prepares pure nickel N6 rod surface gradient structure and is identical with embodiment 1, adopts this device to prepare the method for pure nickel N6 rod surface gradient structure, comprises the following steps:

[0033] The pure nickel N6 alloy ingot obtained by vacuum electromagnetic stirring smelting is cut into a cylindrical billet of Φ30mm×15mm by wire electric discharge cutting, and then the pure nickel N6 cylindrical billet is heated to 350°C and kept for 30 After 10 minutes, evenly smear solid graphite lubricant powder on the surface of the cylindrical blank, and simultaneously apply graphite lubricant powder on the surface of the extrusion cylinder 7, the surface of the extrusion channel 9, and the surface of the groove 8, and put the heated cylindrical blank into the extrusion Inside the cylinder 7, the upper die 6 starts to move, and the die 3 exerts pressure on the blank to start extrusion. The extrusion t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com