Aerospace material pressure forming device

An aerospace, pressure forming technology, used in springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc., to achieve the effect of convenient and quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

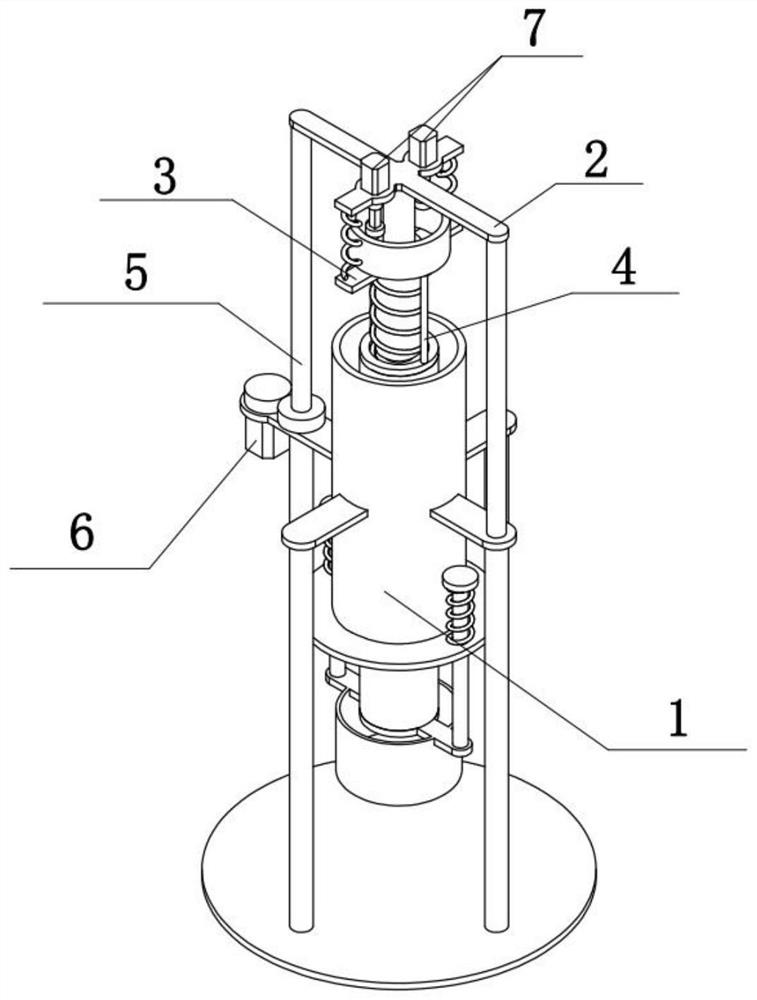

[0031] Combine below Figure 1-8 To illustrate this embodiment, the aerospace material pressure molding device includes a variable housing assembly 1, a pressing assembly 2, a processing assembly 3, an adjusting assembly 4, a lifting assembly 5, a driving assembly 6, and a rotating assembly 7. The pressing assembly Component 2 is slidingly connected to the variable housing component 1, the processing component 3 is connected to the pressing component 2, the adjusting component 4 is connected to the processing component 3, the lifting component 5 is fixedly connected to the pressing component 2, and the lifting component 5 is rotatably connected to the On the variable housing assembly 1, the driving assembly 6 is fixedly connected to the variable housing assembly 1, the driving assembly 6 and the lifting assembly 5 are engaged for transmission, and there are two rotating assemblies 7, both of which are fixedly connected to the pressing On the component 2, the two rotating compo...

specific Embodiment approach 2

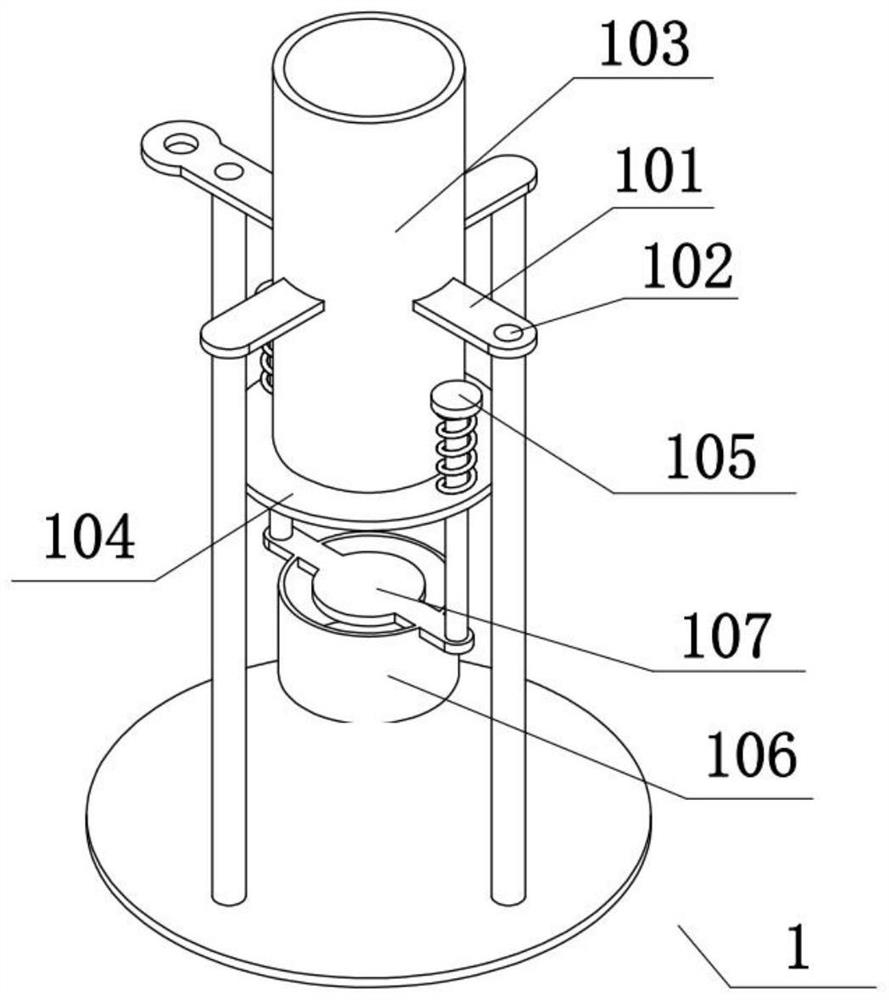

[0034] Combine below Figure 1-8 To illustrate this embodiment, the variable housing assembly 1 includes a base 101, a guide hole 102, a forming tube 103, a guide plate 104, a guide rod 105, a loading frame 106, and a sealing plate 107, and the base 101 is provided with two Guide hole 102, forming tube 103 is fixedly connected on the base 101, the lower end of forming tube 103 is fixedly connected with guide plate 104, and guide plate 104 is slidably connected with two guide rods 105, between two guide rods 105 and guide plate 104 Springs are fixedly connected between them, a loading frame 106 is fixedly connected to the two guide rods 105 , and a sealing plate 107 is fixedly connected to the loading frame 106 .

specific Embodiment approach 3

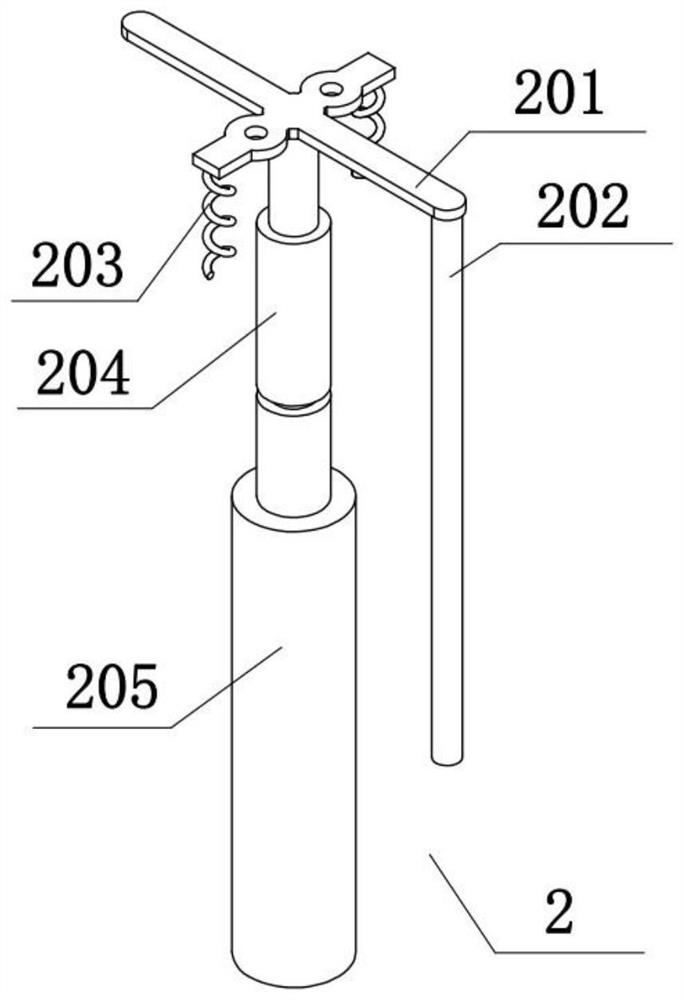

[0036] Combine below Figure 1-8To illustrate this embodiment, the press-down assembly 2 includes a press-down bracket 201, a press-down guide rod 202, a buffer spring 203, a threaded rod 204, and a push-out rod 205, and the press-down bracket 201 is fixedly connected with a press-down guide rod 202, The push-down guide rod 202 is slidingly connected in one of the guide holes 102, two buffer springs 203 are fixedly connected to the push-down bracket 201, the threaded rod 204 is fixedly connected to the push-down bracket 201, and the push-out rod 205 is fixedly connected to the threaded rod 204 superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com