Observation window cleaning equipment for numerically-controlled machine tool

A technology for CNC machine tools and cleaning equipment, which is applied to metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc. It can solve problems such as inconvenient operation, time-consuming, and difficult cleaning for workers, so as to reduce the difficulty of operation and save Time, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

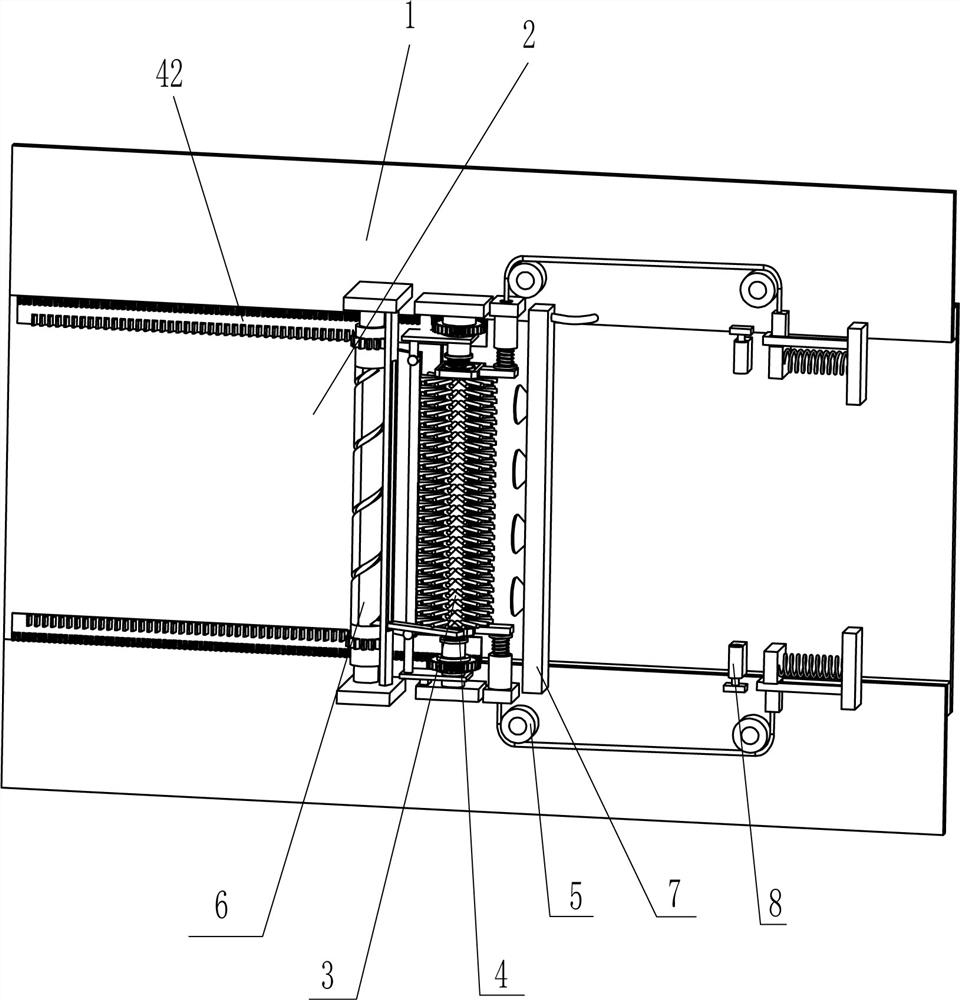

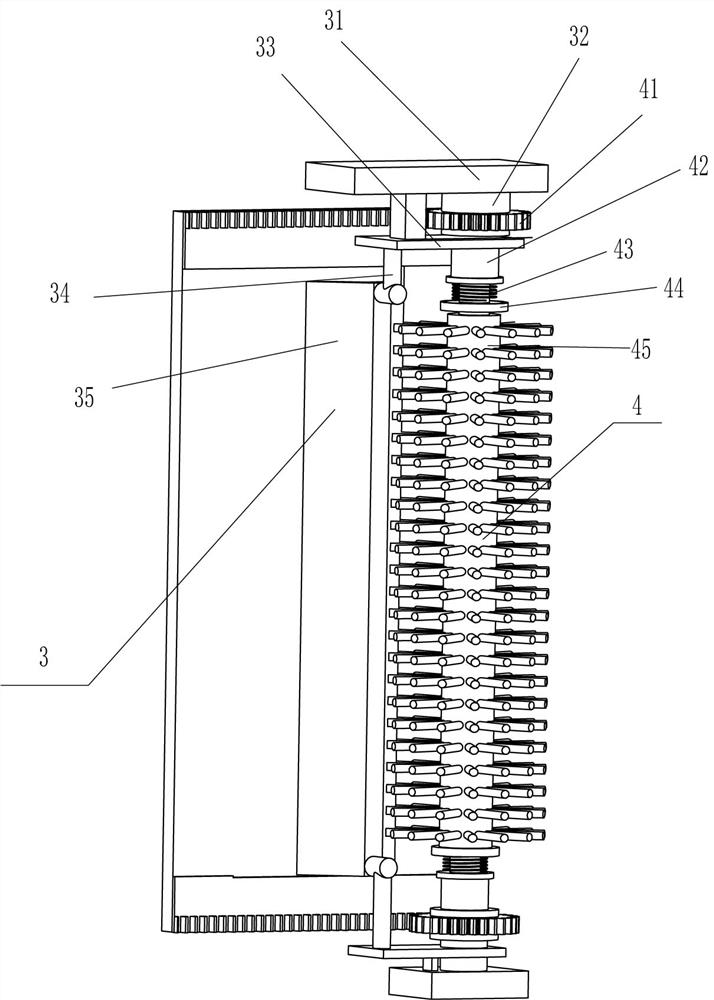

[0029]A observation window cleaning device for CNC machine tools, such asFigure 1-2 As shown, including the fixing plate 1, the double-toothed clamp 22, the foreign matter scraping mechanism 3 and the horizontal cleaning mechanism 4, and the two sides of the front side of the front side of the viewing window 2 are mounted, and the front side of the fixed plate 1 is mounted. Horizontal cleaning mechanisms 4 are mounted on the foreign body scraping mechanism 3.

[0030]When the entire device is mounted on the CNC machine, the worker pulls the viewing window 2 to the right, the foreign body scraping mechanism 3 can scrape off the foreign matter on the viewing window 2, and the viewing window 2 will drive the double tooth rack 22 to the right. Move, the double-toothed clamp 22 drives the horizontal cleaning mechanism 4, the horizontal cleaning mechanism 4 can clean the foreign matter on the viewing window 2, when the worker pulls the observation window 2, the observation window 2 will driv...

Embodiment 2

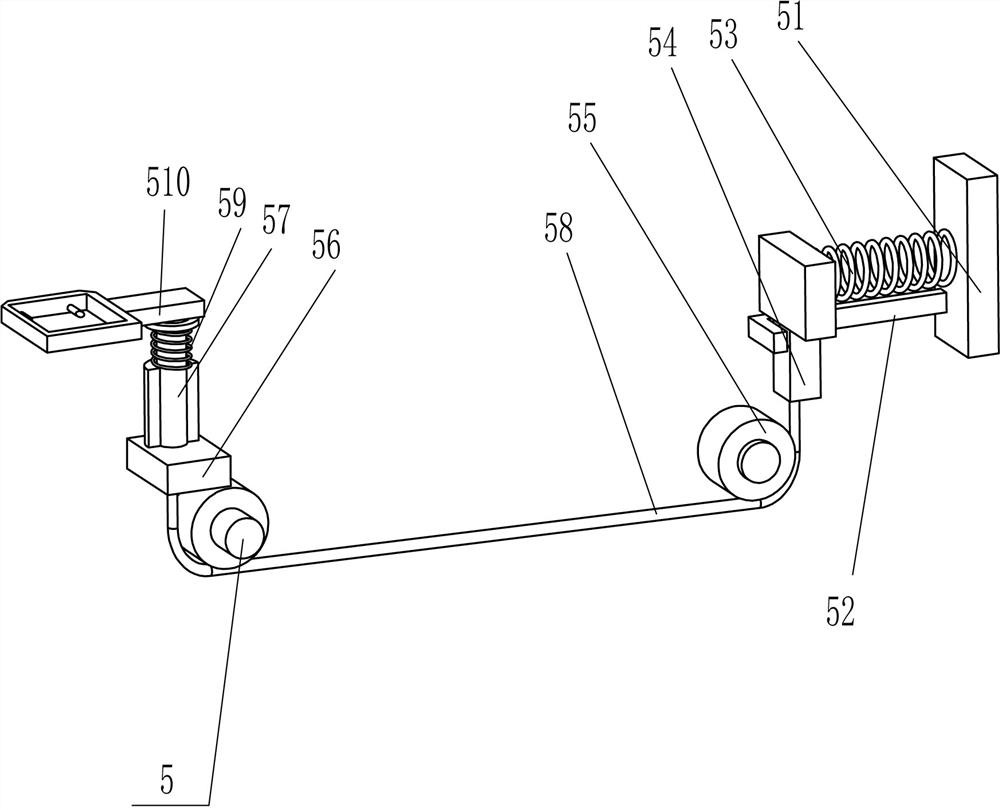

[0036]On the basis of Example 1, such asFigure 3-6The automatic unloading roller mechanism 5 is also included, and the automatic unloading roller mechanism 5 includes a third fixing block 51, a slot block 52, a second spring 53, a slider 54, a limit roller 55, a fourth fixed block 56. The lifting rod 57, the drawing rope 58, the third spring 59 and the fastening frame 510, the upper and lower sides of the front side of the front side of the fixing plate 1 are connected to the third fixing block 51, and the two third fixing blocks 51 are connected. The slot 52, the slot block 52 slides the slider 54, the slider 54 and the third fixing block 51 are connected between the second spring 53, and there are two sides of the upper and lower sides of the front side of the fixed plate 1. The limit roller 55 is located between the two third fixing blocks 51 between the upper and lower sides, and the upper and lower sides of the front side of the fixing plate 1 are connected to the fourth fixed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap