Shoe sole polishing equipment

A technology for shoe soles and equipment, which is applied in the direction of grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of unstable composite bonding structure of shoe soles, lower product quality, high strength and high grinding angle, and improve grinding quality and Grinding efficiency, improving sampling accuracy, and improving the effect of grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

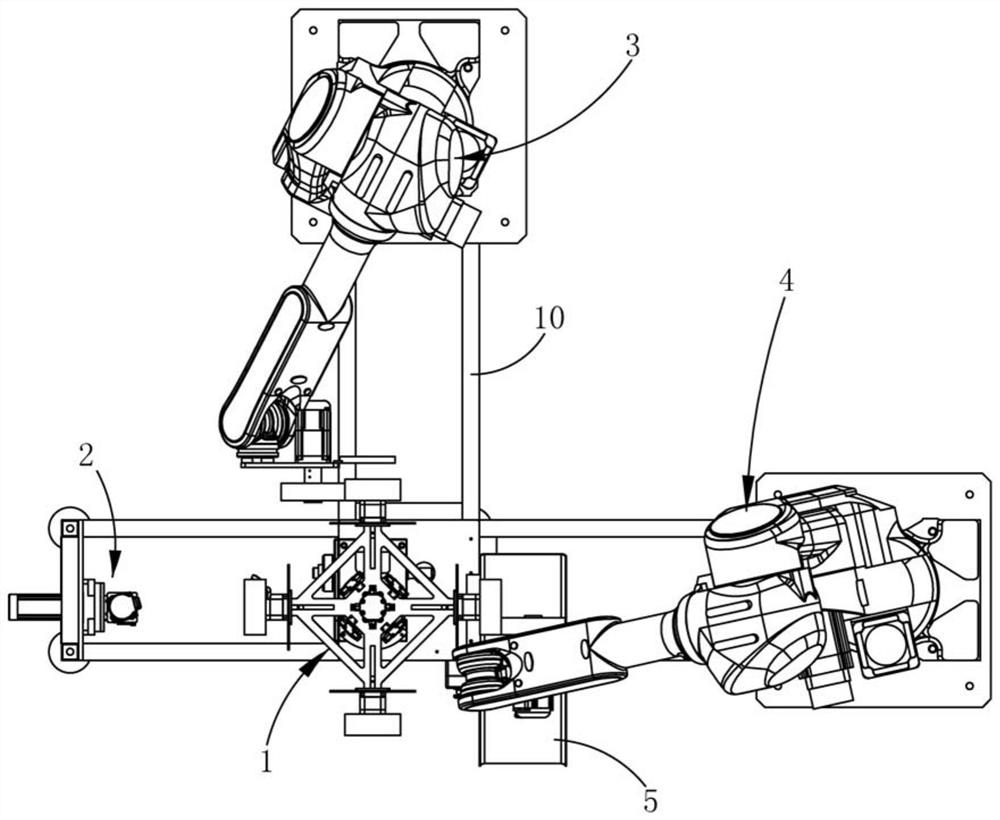

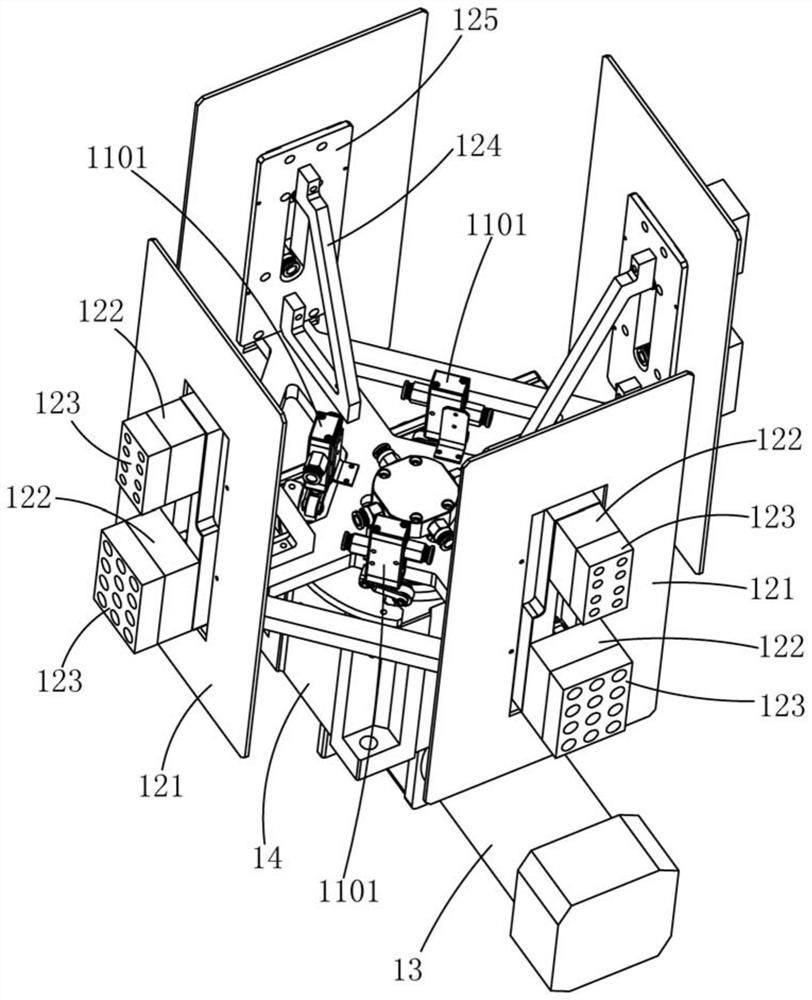

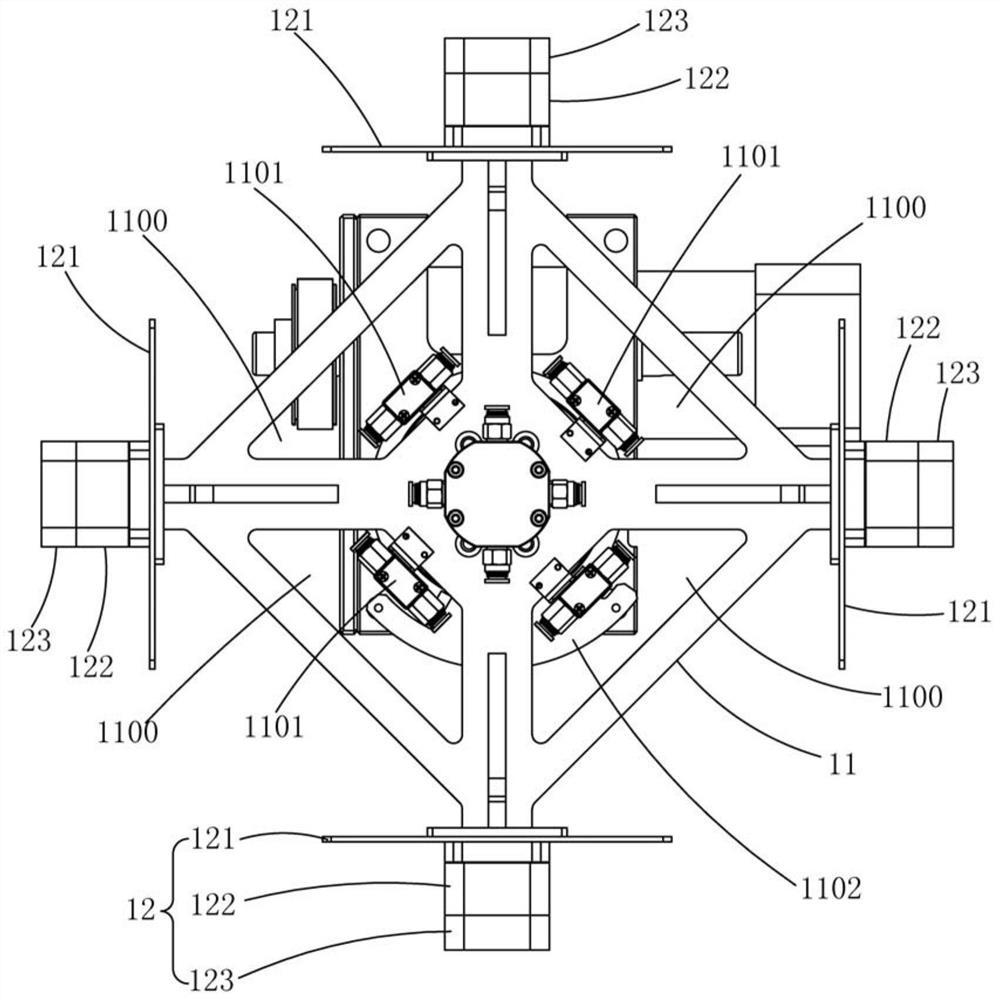

[0027] A kind of shoe sole grinding equipment, such as Figure 1 to Figure 4 As shown, it includes a control device, a frame 10, and a sole gripping device 1 arranged at the center of the frame 10. The first side of the sole gripping device 1 is provided with a feeding position, and the second side is provided with a sampling device for collecting soles. position, the third side is provided with the grinding position 1 used for grinding the side of the sole and the 4th side is provided with the grinding position 2 used as the surface of the sole for grinding; the side of the shoe sole gripping device 1 near the sampling position is provided with a A shoe sole scanning device 2 for clamping position data and three-dimensional contour model data, a side grinding device 3 is arranged on a side near the grinding position one, a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap