Full-automatic unattended propellant sampling machine and preparation method

A propellant, fully automatic technology, applied in the direction of comprehensive factory control, metal processing, etc., can solve the problems of low preparation efficiency, unautomated processing technology, safety risks, etc., to achieve improved safety, low cost, and convenient manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

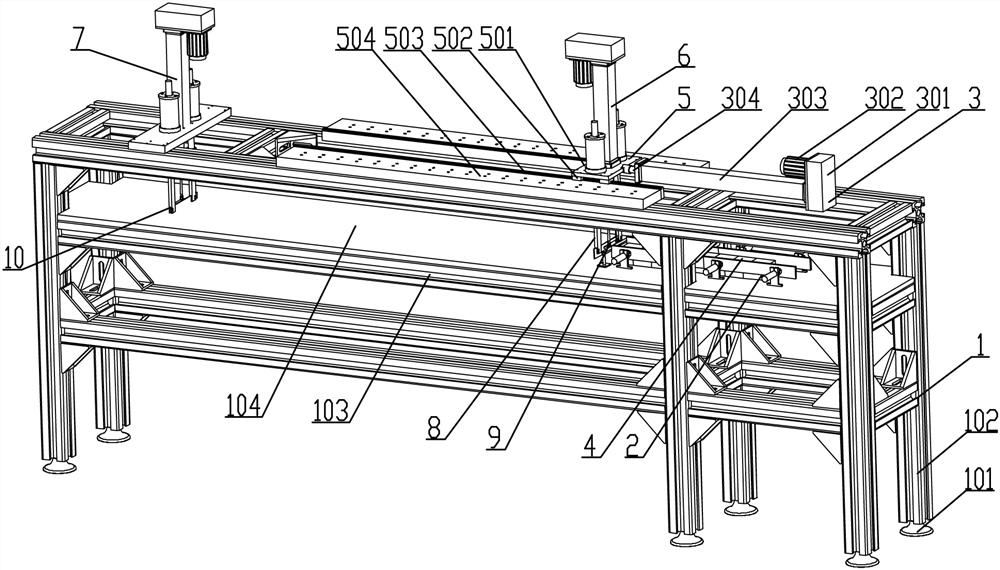

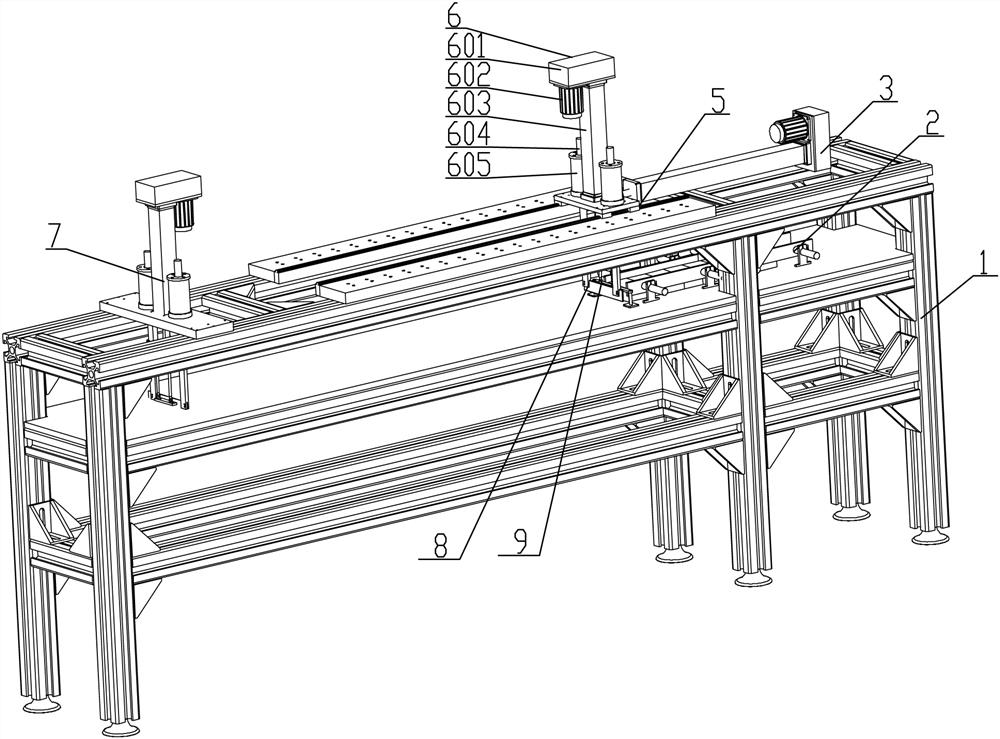

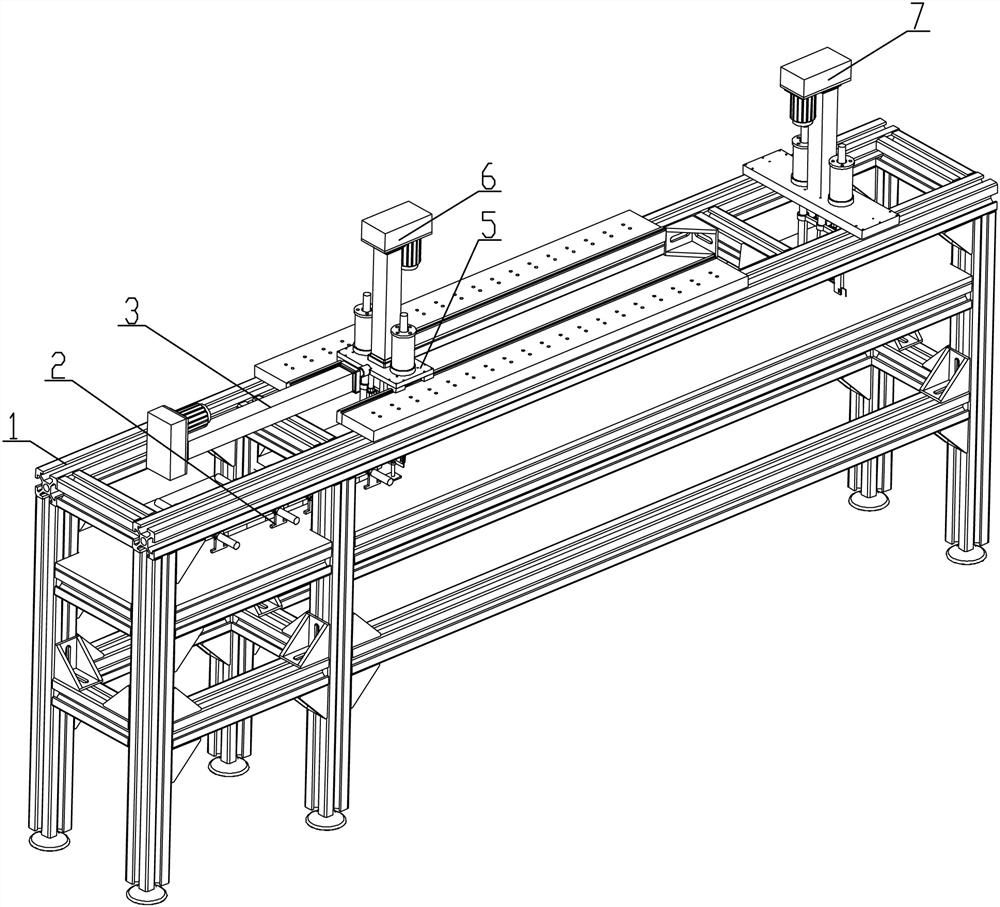

Embodiment 1

[0055] see Figure 1-13 , a fully automatic unattended propellant prototyping machine, which includes a frame structure 1, a slide rail mechanism 5 is arranged at the top middle of the frame structure 1, and a slide rail mechanism 5 for slicing the propellant is fixedly installed on the slide rail mechanism 5. The first cut-off power mechanism 6, the bottom end of the first cut-off power mechanism 6 is fixed with the first cutter assembly 8; the slide rail mechanism 5 is connected with the propulsion mechanism 3 for pushing it to move, and the propulsion mechanism 3 is fixed on the machine The top of the frame structure 1; the feeding guide structure 2 for conveying the propellant drug blank 4 is docked directly under the first cutter assembly 8; the tail section of the frame structure 1 is supported and installed with a The medicine bar cut is made into the second dumbbell-shaped cutting power mechanism 7, and the bottom end of the second cutting power mechanism 7 is fixed wi...

Embodiment 2

[0074] see Figure 14 A method for preparing a propellant sample by a fully automatic unattended propellant sample preparation machine, comprising the following steps:

[0075] Step 1: Place the preliminarily cut propellant billet 4 between the segmented baffles 203 on both sides of the feed guide structure 2, and push the linearly placed propellant billet 4 along the feed guide structure 2 Transport forward so that it reaches the position directly below the first cutter assembly 8;

[0076]Step 2: After the propellant billet 4 is in place, start the first cutting power mechanism 6, drive the second push rod 606 through the second explosion-proof servo motor 602 and the second transmission box 601, and drive the first cutting rod 606 through the second push rod The knife assembly 8 slices the propellant drug blank 4 through the first cutter 803 of the first cutter assembly 8. During the slicing process, the height of the up and down stroke of the first cutter 803 matches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com