Burr removing equipment suitable for outer surface of ball bladder, and removing method

A technology for removing burrs and bladders, which is applied in metal processing, etc., and can solve problems such as the influence of burrs removal rate, uneven processing quality, time-consuming and labor-intensive problems, and achieve the effects of high cutting consistency rate, fast cutting speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

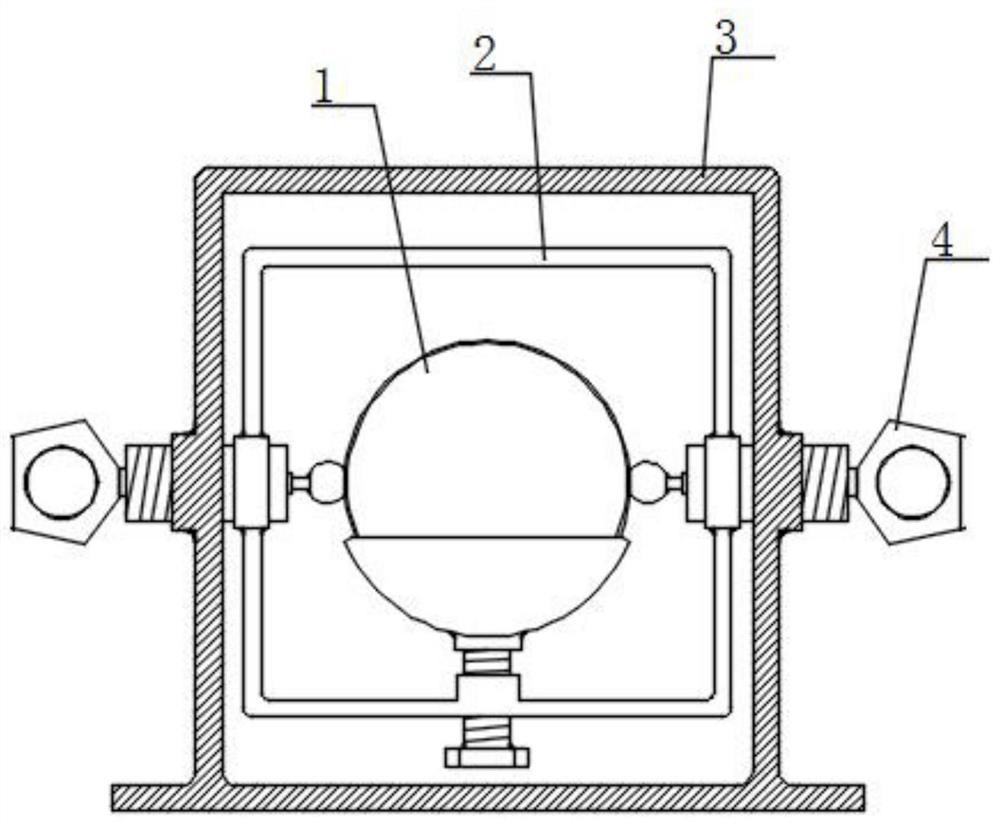

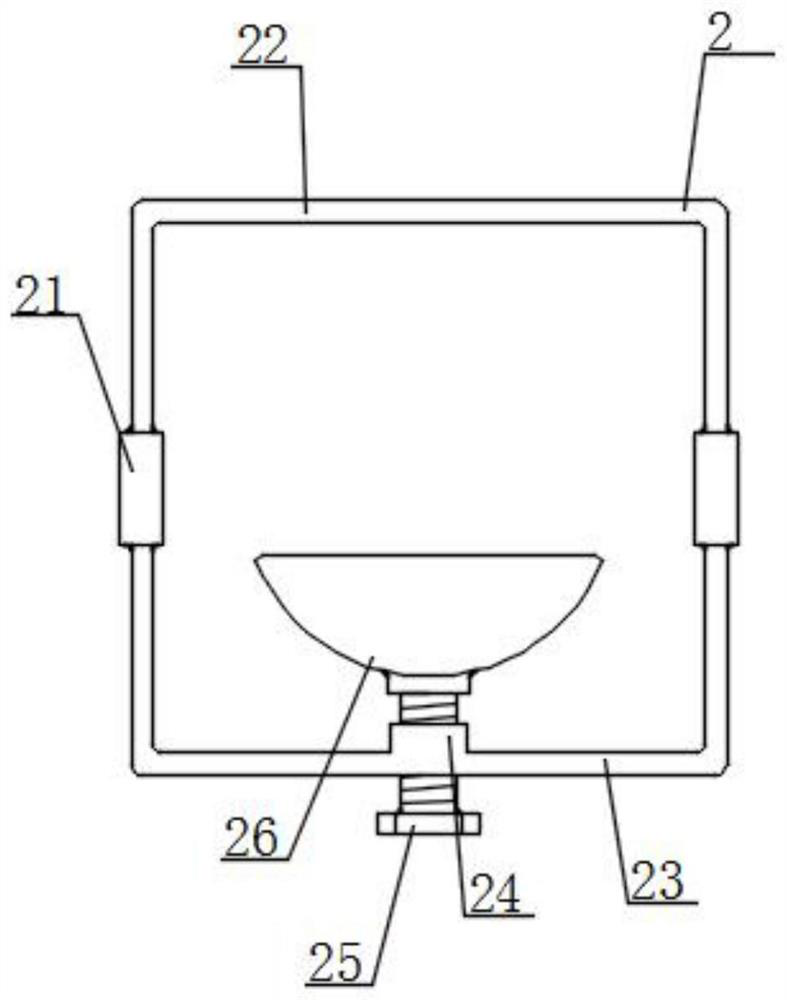

[0027] Such as Figure 1-2 As shown, a device suitable for deburring the outer surface of a ball bladder includes a bearing frame 3 and an internal thread channel. An overturning component 2 is provided, and both sides of the overturning component 2 are penetrated by the drive component 4;

[0028] Turnover assembly 2 comprises collar 21, U-shaped rod 22, U-shaped positioning rod 23, sleeve pipe 24, threaded insert rod 25 and cutting bowl 26, and U-shaped rod 22 is arranged in the carrying frame 3, and the opposite part of U-shaped rod 22 A U-shaped positioning rod 23 is provided; a collar 21 is provided at the protruding part of the driving assembly 4 relative to the bearing frame 3, and the collar 21 is set on the driving assembly 4; the ends of the U-shaped rod 22 and the U-shaped positioning rod 23 are symmetrical Fixed to both sides of the collar 21, a sleeve 24 runs through the midpoint of the U-shaped positioning rod 23, and a threaded insertion rod 25 is bolted inside...

Embodiment 2

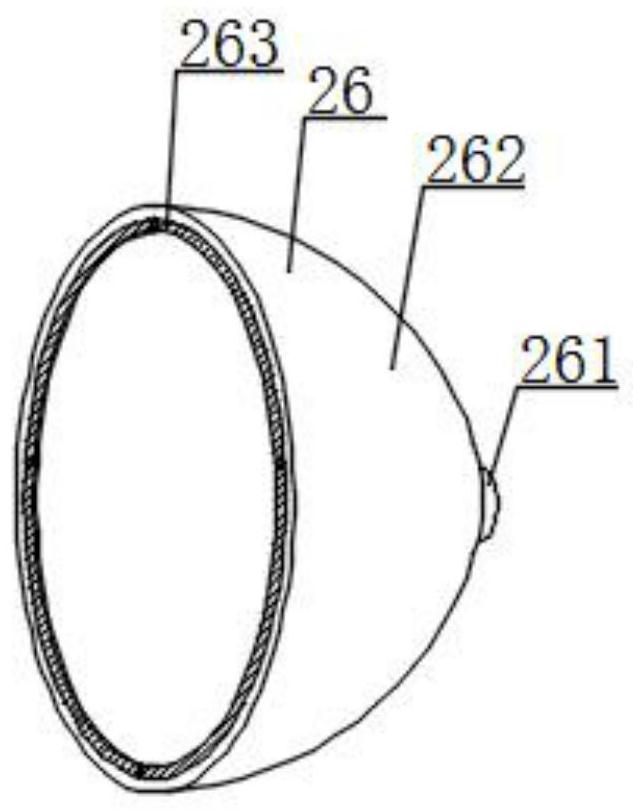

[0032] Such as Figure 1-3 As shown, a device suitable for deburring the outer surface of the bladder, the cutting bowl 26 is covered with a bladder 1, and the two ends of the bladder 1 are clamped by the drive assembly 4; the cutting bowl 26 includes a sleeve cup 261, a bowl body 262 and a ring blade 263, the bladder 1 is placed in the bowl 262, the port of the bowl 262 is fixedly connected with an annular blade 263, the surface of the bowl 262 is fixed with a cup 261 away from the port, and the cup 261 is sleeved to the threaded socket Rod 25; wherein the inner diameter of the annular blade 263 is set to be consistent with the port inner diameter of the bowl 262, the bowl 262 is matched with the bladder 1, and the outer surface of the bladder 1 is in contact with the inner wall of the bowl 262 shape.

[0033] In this embodiment, the bladder 1 and the bowl 262 are arranged in a matching manner, that is, when the bladder 1 rotates relative to the bowl 262, the excess burr is ...

Embodiment 3

[0035] Such as figure 1 with 4 As shown, a device suitable for deburring the outer surface of the bladder, the drive assembly 4 includes a contact head 41, a threaded cup body 42, a motor 43 and a handle 44, a threaded cup body 42 is bolted in the inner threaded channel, and the threaded cup body 42 A motor 43 is embedded inside, and the transmission shaft at the motor 43 is extended relative to the threaded cup body 42; a contact head 41 is provided on one side of the threaded cup body 42, and the contact head 41 is socketed and fixed to the transmission shaft, and the contact head 41 is placed on the flip side In the rectangular area selected by the component 2 ; the other side of the threaded cup body 42 is fixed with a handle 44 , which is outwardly extended relative to the bearing frame 3 .

[0036] In this embodiment, the driving assembly 4 is both a clamping assembly and a kinetic energy output assembly, that is, the movement between the driving assemblies 4 relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com