Method for producing melamine composite floor

A technology of melamine and composite flooring, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of easy scratches, affecting service life and aesthetics, shorten the production cycle, strengthen the durability Abrasion resistance and scratch resistance, the effect of improving wear resistance and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

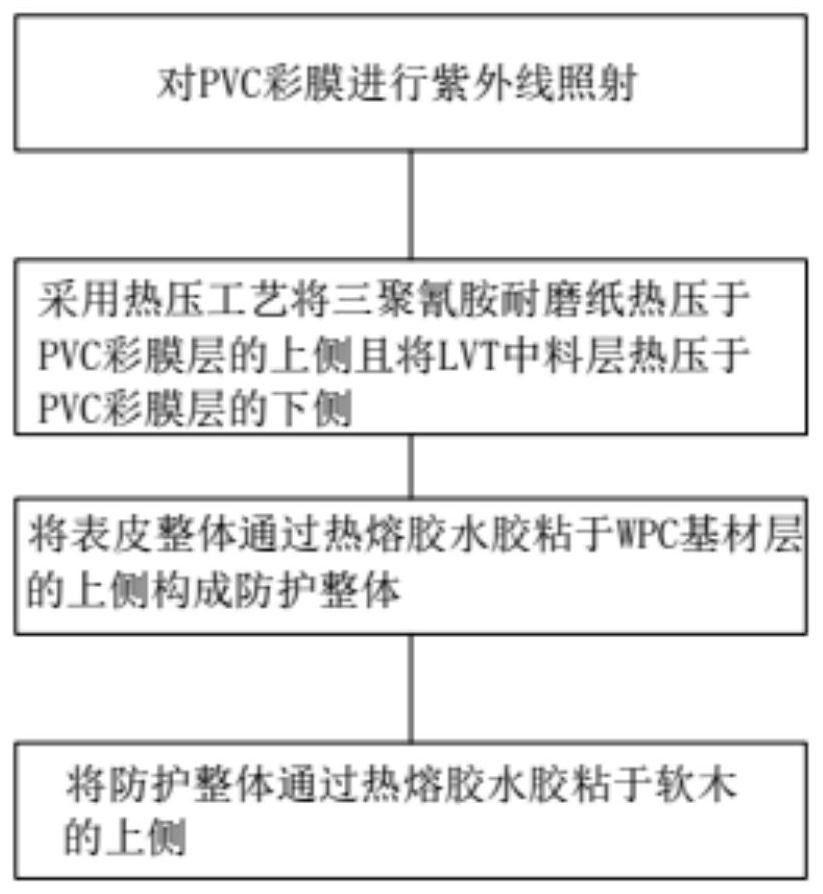

[0018] Such as figure 1 Shown, be a kind of method of producing melamine composite floor of the present invention, comprise the steps:

[0019] Step 1: UV irradiating the PVC color film;

[0020] Step 2: heat-press the melamine wear-resistant paper on the upper side of the PVC color film layer and hot-press the LVT middle material layer on the lower side of the PVC color film layer by hot pressing process, so as to form the whole skin;

[0021] Step 3: Glue the whole skin to the upper side of the WPC substrate layer with hot melt glue to form a protective whole;

[0022] Step 4: Glue the protective whole to the upper side of the cork with hot-melt glue.

[0023] Specifically, the method of producing melamine composite flooring is to first irradiate the PVC color film with ultraviolet light, and then heat-press the melamine wear-resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com