A metal alloy composite ceramic plate and its preparation process

A composite ceramic plate and metal alloy technology, which is applied in the field of composite materials, can solve the problems of low tensile strength, plasticity and toughness, and achieve good thermal shock resistance, performance improvement, hardness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation process of a metal alloy composite ceramic plate, comprising the following steps:

[0046] Step 1: Take 50-65 parts of alumina particles, 28-43 parts of zirconia particles, 0.5-2 parts of silicon carbide, 0.5-1.95 parts of silicon dioxide, 0.01-0.05 parts of yttrium oxide and 1.5 parts of titanium carbide as the ceramic raw material of the ceramic matrix. -3 parts, they are put into the ball mill and ground for 10-16 hours, and the ceramic raw material components of the ceramic matrix are obtained after mixing evenly, and are set aside; get titanium powder, aluminum powder, zirconium powder, chromium powder, iron powder, magnesium powder, At least two raw materials in the rare earth powder are put into a ball mill and ground for 4-8 hours, and after being mixed evenly, they become the raw material components of the metal alloy body, and then sent to the melting furnace at a melting temperature of 1560-1850°C to be smelted into a semi-solid or liquid metal ...

Embodiment 1

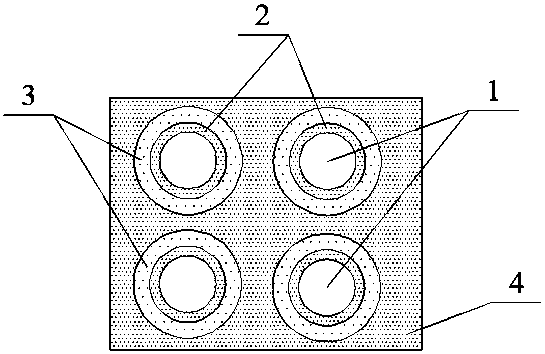

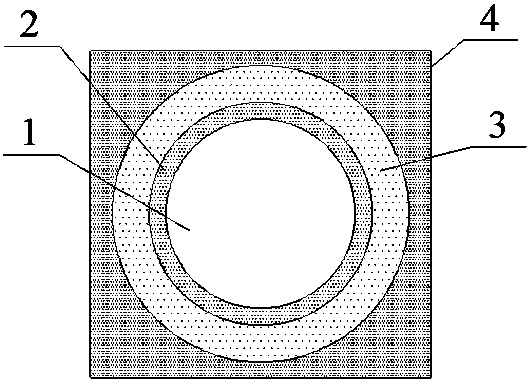

[0070] Such as figure 1 The shown metal alloy composite ceramic board includes several metal alloy composite ceramic board substrates and ceramic connector II wrapping the metal alloy composite ceramic board substrate; the metal alloy composite ceramic board substrate includes ceramic connector I2, ceramic substrate 3 and the metal alloy body 1, the ceramic connecting body I2 is located between the ceramic matrix 3 and the metal alloy body 1, and its preparation process includes the following steps:

[0071] Step 1: Take the ceramic raw materials of the ceramic matrix: 50-65 parts of alumina particles with a particle size of 2-100 nm, 28-43 parts of zirconia particles with a particle size of 2-200 nm, and carbonized particles with a particle size of 0.5-1.5 μm 0.5-2 parts of silicon, 0.5-1.95 parts of nano-particle silicon dioxide, 0.01-0.05 parts of nano-particle yttrium oxide and 1.5-3 parts of titanium carbide with a purity ≥ 99.0%, put them into a ball mill and grind them ...

Embodiment 2

[0088] Such as figure 2 The shown metal alloy composite ceramic plate includes a metal alloy composite ceramic plate base and a ceramic connector II wrapping the metal alloy composite ceramic plate base; the metal alloy composite ceramic plate base includes a ceramic connector I2, a ceramic base 3 and The metal alloy body 1, the ceramic connecting body I2 is located between the ceramic matrix 3 and the metal alloy body 1, and its preparation process includes the following steps:

[0089] Step 1: Take the ceramic raw materials of the ceramic matrix: 62 parts of alumina particles with a particle size of 80 nm, 30 parts of zirconia particles with a particle size of 100 nm, 1.5 parts of silicon carbide with a particle size of 0.5-1.5 μm, and nanoparticles 1.95 parts of silicon, 0.05 parts of nanoparticle yttrium oxide and 2.5 parts of titanium carbide with a purity ≥ 99.0%, put them into a ball mill and grind them for 10-16 hours, and mix them uniformly to obtain the ceramic raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com