Full-automatic chain bag sealing, boxing and casing packaging production line

A packaging production line, box packaging technology, applied in packaging, transportation packaging, transportation and packaging, etc., to achieve good results, easy to observe the operation of equipment, and improve packaging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

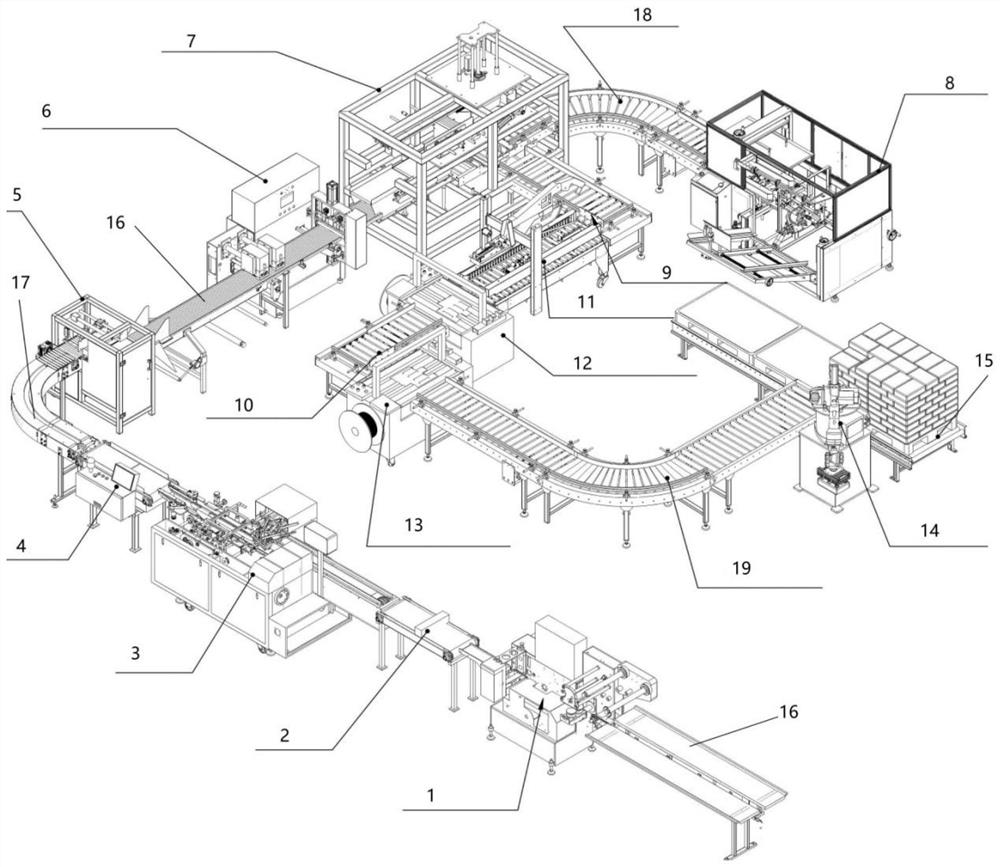

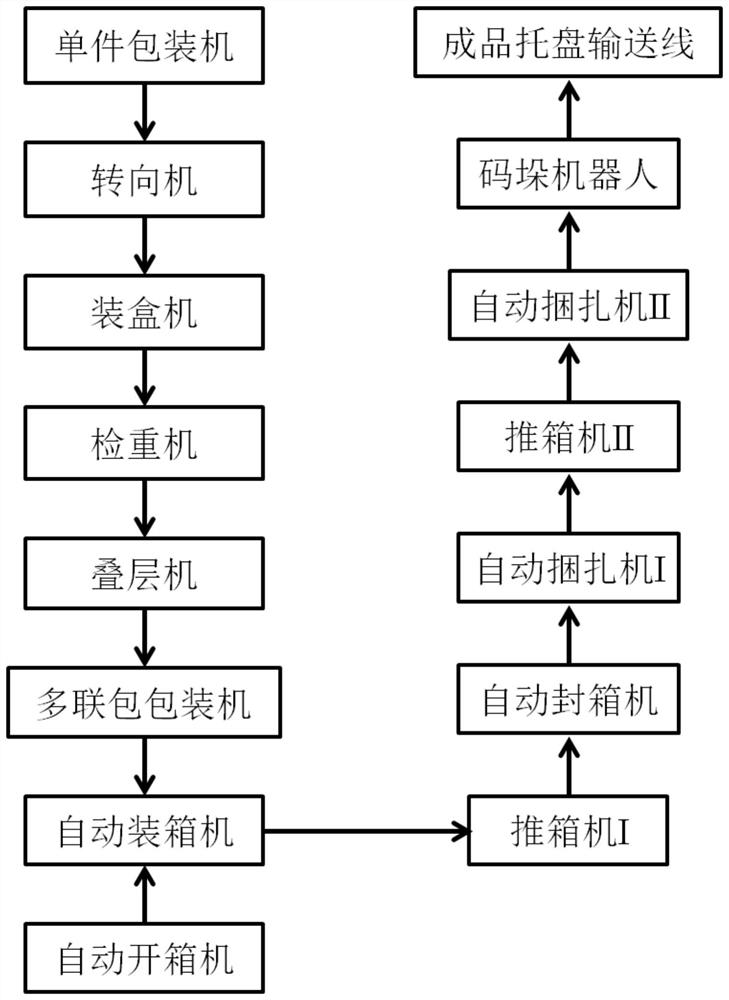

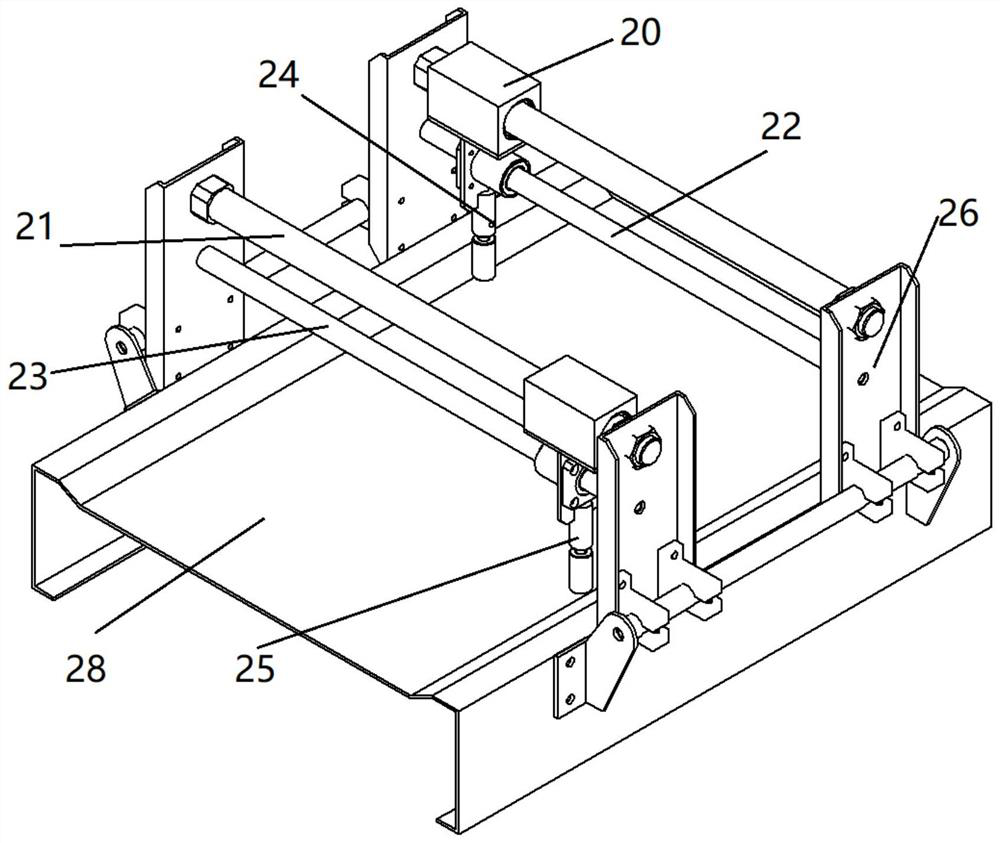

[0059]ReferFigure 1-3Among the automatic chain sealing bag, packaging and packaging packaging production line, including single piece packaging machine 1, steering machine 2, box machine 3, checker 4, laminate 5, multi-package packaging machine 6 , Automatic packing machine 7, automatic unpacking machine 8, push box machine I9, push box machine II 10, automatic sealing machine 11, automatic strapping machine I12, automatic strapping machine II 13, palletizing robot 14, finished tray conveying line 15, belt conveyor 16, flat top chain board conveyor 17, drum conveyor 18, and chain finished delivery machine 19, each single device is controlled by the PLC control system;

[0060]The discharge port of the single-piece packaging machine 1 is disposed at the front end position of the steering machine 2, the rear end position of the steering machine 2 corresponds to the fitting of the cartridge machine 3, and the position of the cartridge machine 3 is disposed in the detector 4. The front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com