Water supply equipment

A technology of water supply equipment and water inlet pipes, which is applied in water/sewage treatment, multi-stage water/sewage treatment, light water/sewage treatment, etc., and can solve problems such as unfavorable users, easy scaling of tanks, and poor water storage environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

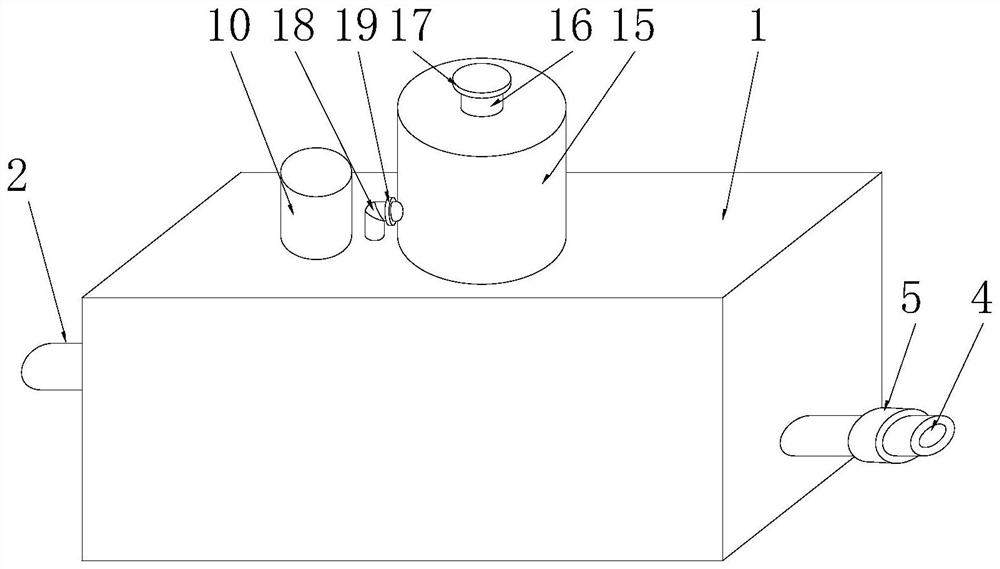

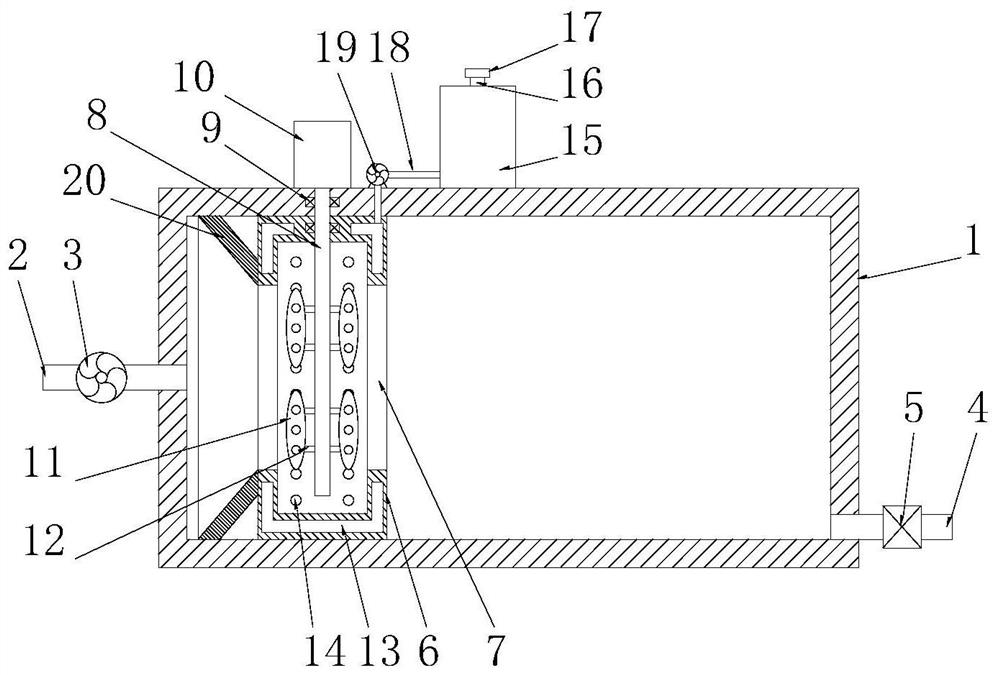

[0019] See Figure 1-2 , a water supply device, comprising a tank body 1, one end of the tank body 1 is connected to a water inlet pipe 2, and the other end of the tank body 1 is connected to a water outlet pipe 4, and a control valve 5 is installed on the water outlet pipe 4. A water inlet pump 3 is installed on the water inlet pipe 2, and a mixing cylinder 6 is provided in the inner cavity of the tank body 1. The left and right side ends of the mixing cylinder 6 are connected with a communication hole 7, and the end of the mixing cylinder 6 near the water inlet pipe 2 is provided with a The diversion bucket 20 matched with the communication hole 7, the mixing cylinder 6 is provided with a mixing shaft 8, the axis of the mixing cylinder 6 coincides with the axis of the mixing shaft 8, and the top of the mixing shaft 8 runs through the top wall and the mixing cylinder 6. The top wall of the tank body 1 is rotatably connected to the mixing motor 10, the mixing shaft 8 is rotata...

Embodiment 2

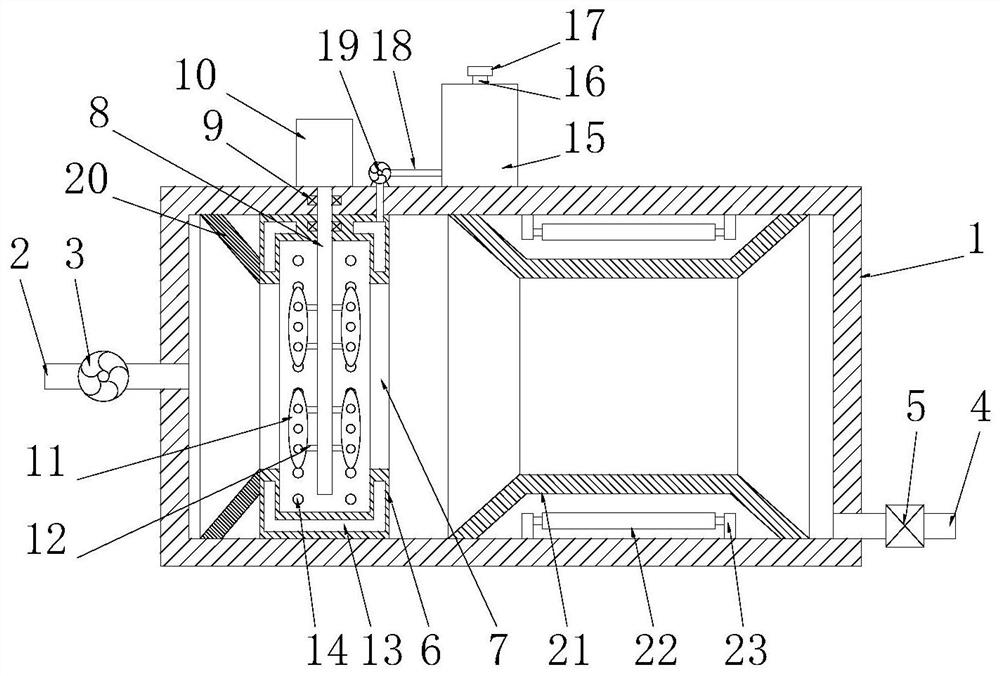

[0022] See image 3 , and the difference from Embodiment 1 is that: the inner cavity of the tank body 1 is also provided with an isolation cover 21, the isolation cover 21 is an annular structure, and the isolation cover 21 is arranged on the right side of the mixing cylinder 6, and the isolation cover 21 The unilateral cross-section of 21 is an isosceles trapezoidal structure, and the isolation cover 21 is made of transparent glass. The inner cavity of the isolation cover 21 is uniformly provided with a number of ultraviolet lamps 22, and the ultraviolet lamps 22 are fixedly installed on the tank through the feet 23. On the inner cavity wall of the tank body 1, ultraviolet rays are irradiated by the ultraviolet lamp 22, and the ultraviolet lamp tube is used to penetrate the isolation cover 21 to realize ultraviolet irradiation disinfection of the water in the tank body 1, and cooperate with the disinfection of the medicinal solution in the mixing cylinder 6, thereby further T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com