Filling modified PP material and preparation method thereof

A modification and main ingredient technology, applied in the field of filling modified PP materials and its preparation, can solve problems such as poor linearity, warping of parts, low shrinkage, etc., and achieve the effect of improving distribution uniformity and eliminating orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

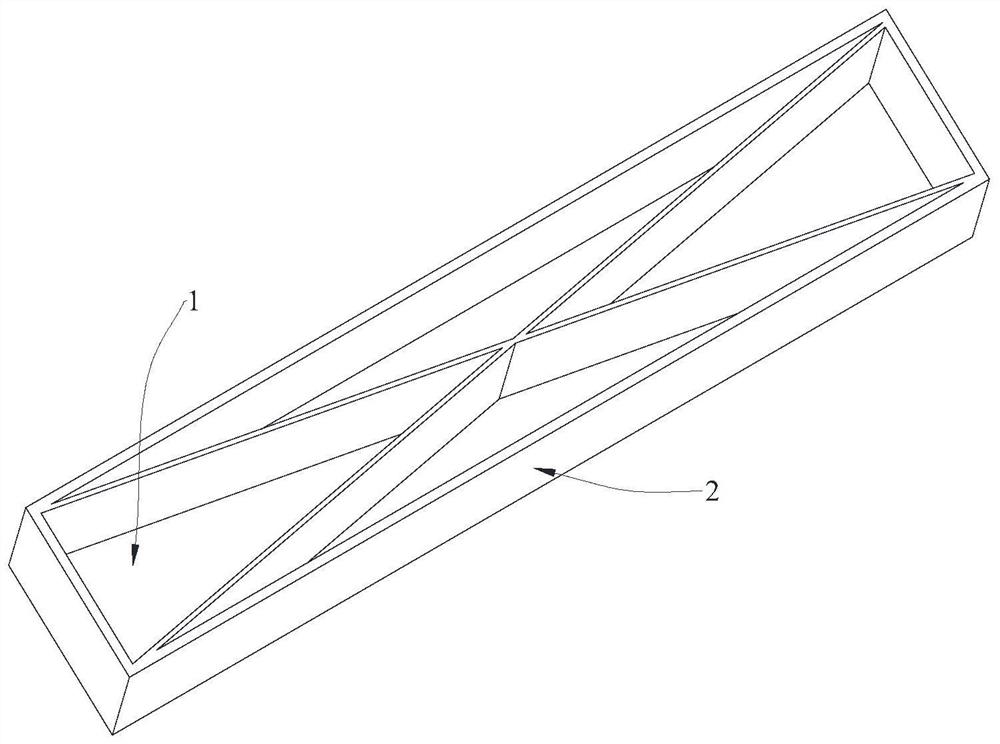

Image

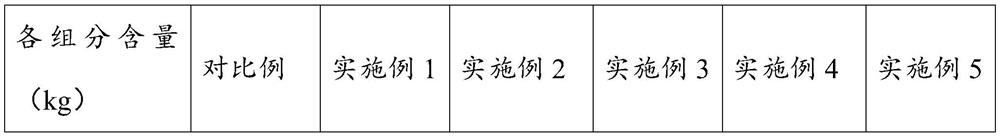

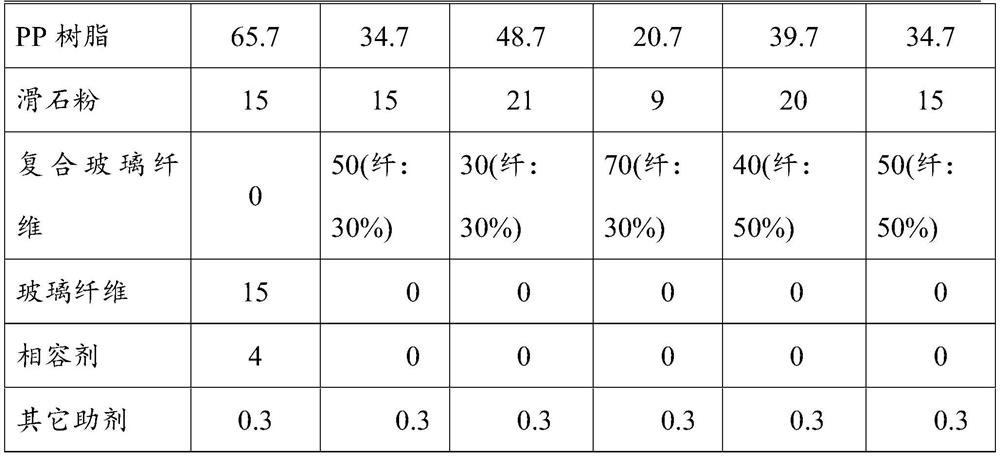

Examples

Embodiment approach

[0046] In one embodiment of the present invention, the diameter of the glass fiber in the composite glass fiber is 1-20 μm, and the length is 1-10 mm. It is preferable to use glass fibers with a diameter of 5-15 μm and a length of 5-10 mm.

[0047] In the filled modified PP material of the present invention, the processing aid includes one or a mixture of antioxidants and lubricants.

[0048] In one embodiment of the present invention, the filled modified PP material of the present invention further includes 0.01-3 parts of a compatibilizer.

[0049] The preparation method of the filled modified PP material described in this embodiment comprises the following steps:

[0050] Mixing step: adding PP resin, talc powder and processing aids into a high-speed mixer and mixing to obtain a mixed material;

[0051] Feeding step: first put the compound into the solid main material port of the extruder, and then put the composite glass fiber into the side feeding port of the extruder t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com