Quick-cooling anti-impact PPR pipe as well as preparation method and application thereof

A quick-cooling and pipe technology, which is applied in the field of quick-cooling and impact-resistant PPR pipes and their preparation, can solve the problems of poor low-temperature impact resistance, low production efficiency, and long cooling time of PPR pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0034] This embodiment provides a series of quick-cooling and impact-resistant PPR pipes. According to the raw material composition in Table 1, the specific preparation includes the following steps:

[0035] After uniformly mixing random copolymerized polypropylene, α-nucleating agent, elastomer toughening agent, talc powder, coupling agent and additives, the uniformly mixed mixture is melted, extruded, and cooled by a single-screw extruder and granulation,. Among them, the temperature of the screw in the single-screw extruder is 185-200°C, the temperature of the mold is 190-205°C, the blank at the die enters the vacuum box for vacuum cooling and shaping, the water tank is cooled, and the length is cut (DN20, 2.0 MPa), to obtain the random copolymerized polypropylene pipe for the rapid cooling type, low-temperature shock-resistant cold and hot water, the thickness of the pipe is 2.8mm.

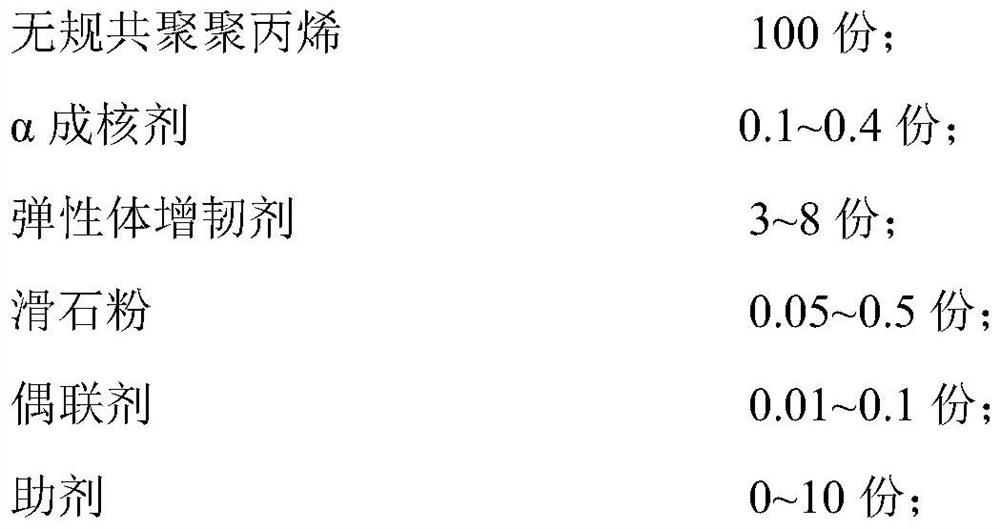

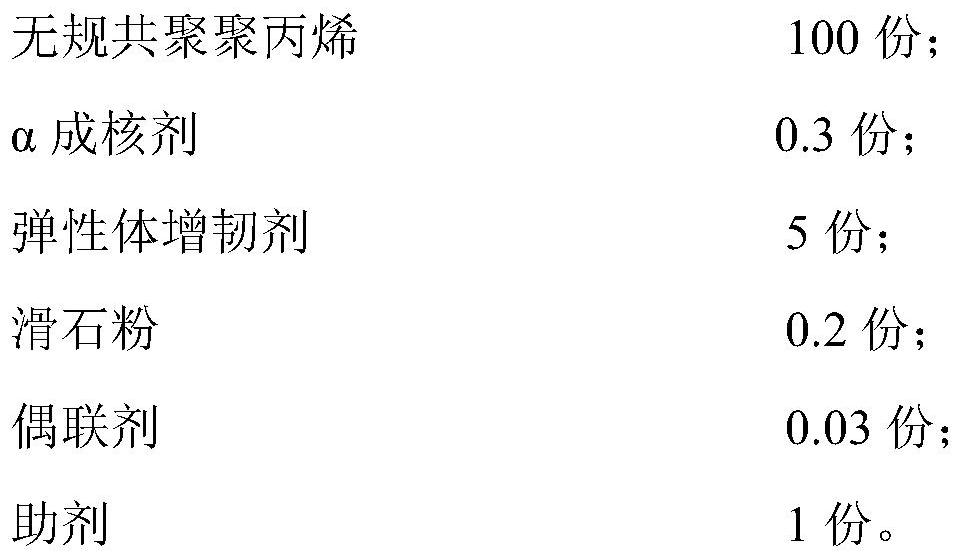

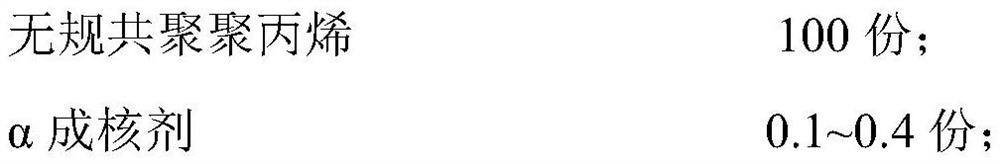

[0036] Each embodiment raw material composition of table 1 (weight part)

[0037]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com