A hemp rope automatic braiding machine for braiding hemp rope

A weaving machine and hemp rope technology, which is applied in the field of weaving machines, can solve the problems of low precision, easy weaving errors, time-consuming and energy-consuming problems, and achieve the effects of improving work efficiency, facilitating work, and avoiding weaving failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

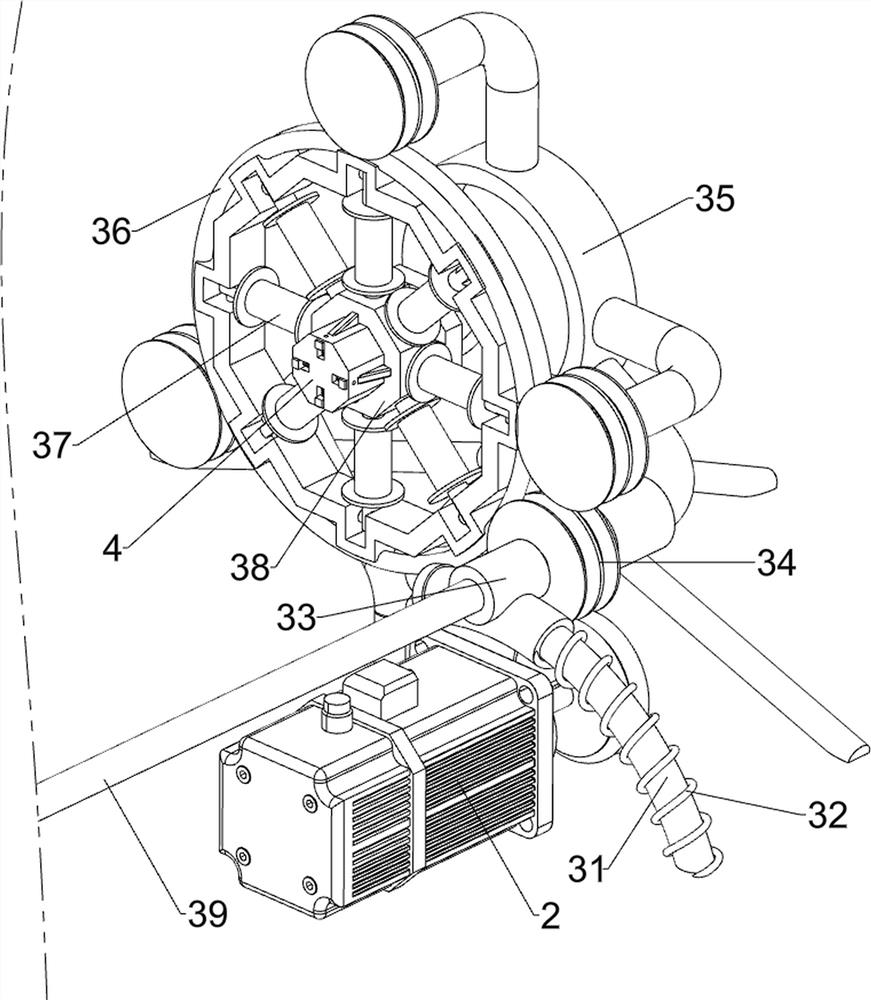

[0066] A hemp rope automatic braiding machine for braiding hemp rope, such as figure 1 As shown, it includes a workbench 1, a motor 2, a rotating mechanism 3 and a locking mechanism 4. A motor 2 is provided in the middle of the front side of the top of the workbench 1, and a rotary mechanism is provided between the right side of the top of the workbench 1 and the output shaft of the motor 2. 3. The rotation mechanism 3 is provided with a locking mechanism 4 .

[0067] When people need to weave hemp ropes, they first wind the ropes around a certain part of the rotating mechanism 3 in turn, and the locking mechanism 4 fixes the hemp ropes, and then starts the motor 2. The output shaft of the motor 2 drives the rotating mechanism 3 to run, and the rotating mechanism 3 Drive the twine to rotate, and at the same time, people hold the other end of the twine and slowly pull it to the left, so that the twine is woven together. When the twine is knitted, turn off the motor 2, and then ...

Embodiment 2

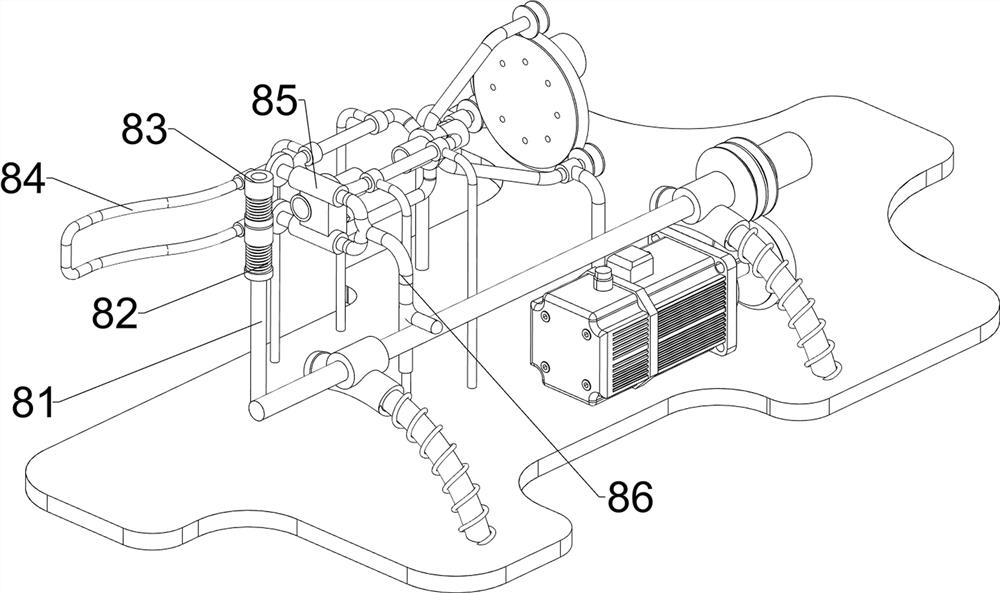

[0069] On the basis of Example 1, as figure 2 , image 3 and Figure 4 As shown, the rotating mechanism 3 includes a first guide frame 31, a first spring 32, a first sliding sleeve 33, a first transmission wheel 34, a first mounting frame 35, a rotating frame 36, a winding assembly 37, and a first fixing block. 38 and the first rotating shaft 39, the front side of the top of the workbench 1 is symmetrically provided with a first guide frame 31, the upper part of the first guide frame 31 is slidably provided with a first sliding sleeve 33, and the front side of the first sliding sleeve 33 is connected to the A first spring 32 is arranged between the front sides of the top of the table 1. The first springs 32 are all sleeved on the outer side of the first guide frame 31 on the same side. 1. A first mounting frame 35 is provided on the right side of the top, the left part of the first mounting frame 35 is evenly rotated with a first transmission wheel 34, and the right part of t...

Embodiment 3

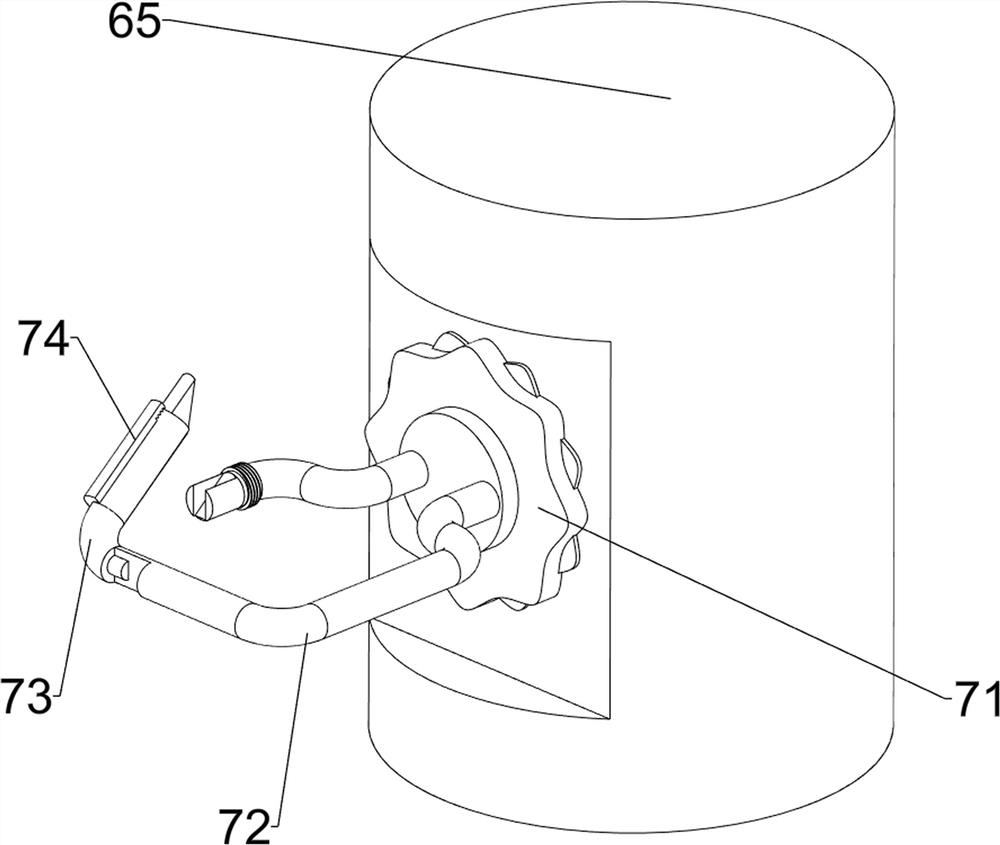

[0076] On the basis of Example 2, as Figure 4 , Figure 5 and Image 6 As shown, a collection mechanism 6 is also included. The collection mechanism 6 includes a bevel gear set 61, a third fixed frame 62, a second rotating shaft 63, a turbine set 64, a third rotating shaft 65, a collecting disc 66 and a grappling hook 67. The workbench 1. A third fixing frame 62 is arranged at the rear of the left side of the top, the upper part of the third fixing frame 62 is rotatably provided with a second rotating shaft 63, and a bevel gear set 61 is arranged between the front part of the second rotating shaft 63 and the left part of the first rotating shaft 39 , the top left rear of the workbench 1 is rotatably provided with a third rotating shaft 65, a turbine group 64 is arranged between the lower part of the third rotating shaft 65 and the rear part of the second rotating shaft 63, and a collecting disc 66 is arranged on the upper part of the third rotating shaft 65 to collect the T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com