Connecting structure and connecting method for PHC precast pile cutting pile top and bearing platform

A technology of prefabricated piles and pile tops, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of restricting the development and use of PHC prefabricated piles, increasing construction risks, affecting the construction period, etc., achieving simple structure and applicability Wide, increase the effect of bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

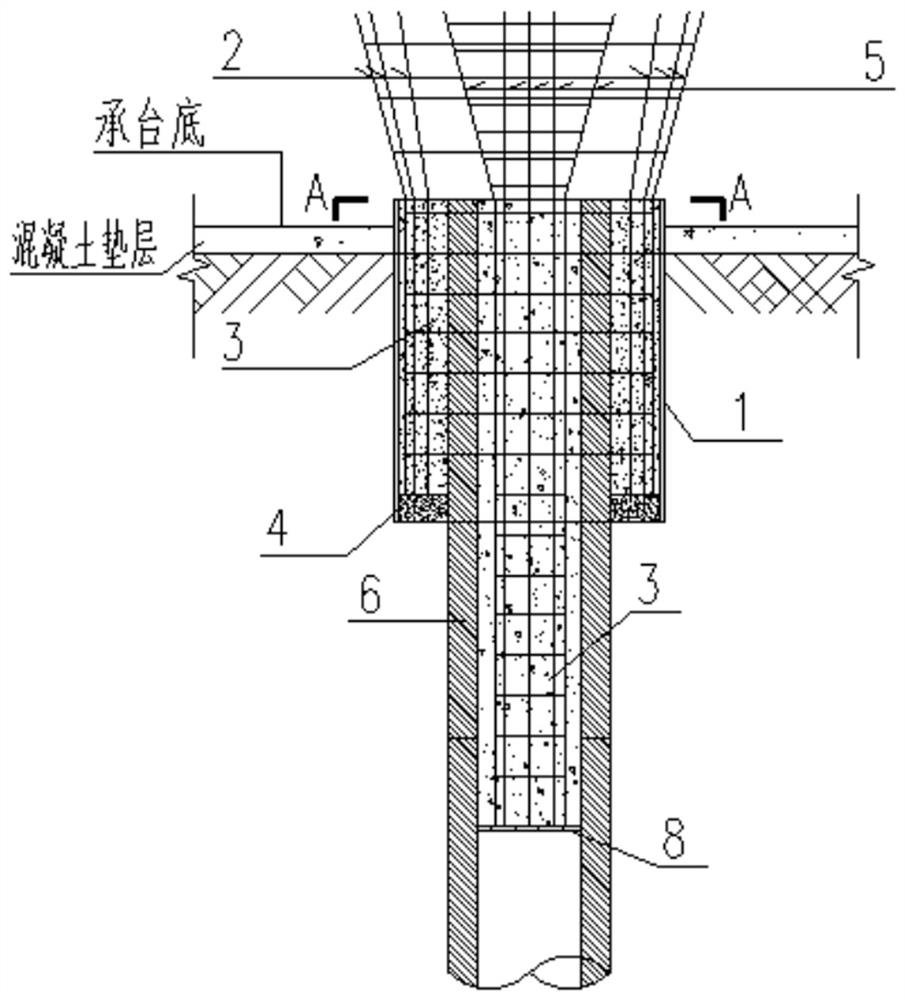

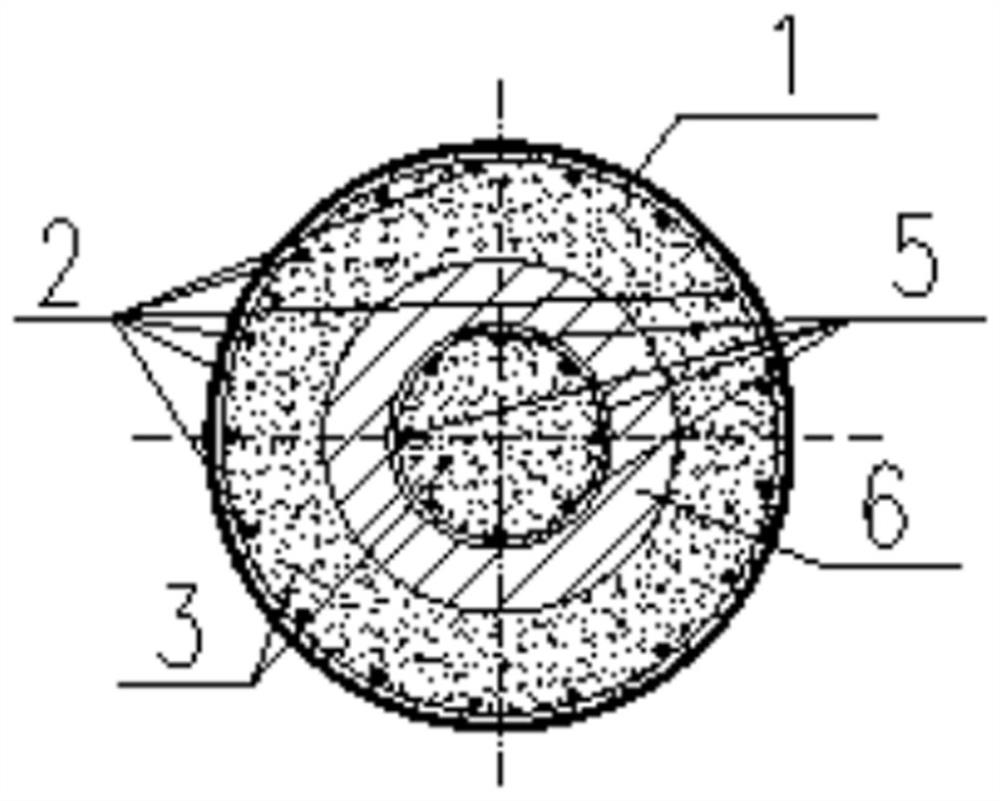

[0015] A new type of structure for the connection between the top of the PHC prefabricated pile and the pile cap. The PHC prefabricated pile 6 forms a hollow core of the pile foundation; A gap of 200mm is reserved between the inner wall of the sleeve 1 and the side wall of the PHC prefabricated pile to form a cavity; the precast pile core and the soil in the cavity are emptied, and the steel sleeve and the side wall of the PHC pipe pile are washed clean. Use C50 back-sealing concrete 4 to seal the cavity, and at the same time set the supporting plate 8 on the pile core, lower the first reinforcement cage 2 and the second reinforcement cage 5 respectively, pour C50 concrete 3 into the cavity and the hollow core of the pile foundation, and then vibrate and compact until the pile top elevation.

[0016] The connection structure of the present invention co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com