Large all-aluminum structure open aluminum plate curtain wall system and installation process thereof

A curtain wall, complete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of easy flow of rust water, inability to form assembly, short weather resistance time, etc., to improve corrosion resistance and weather resistance, reduce adverse effects, installation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

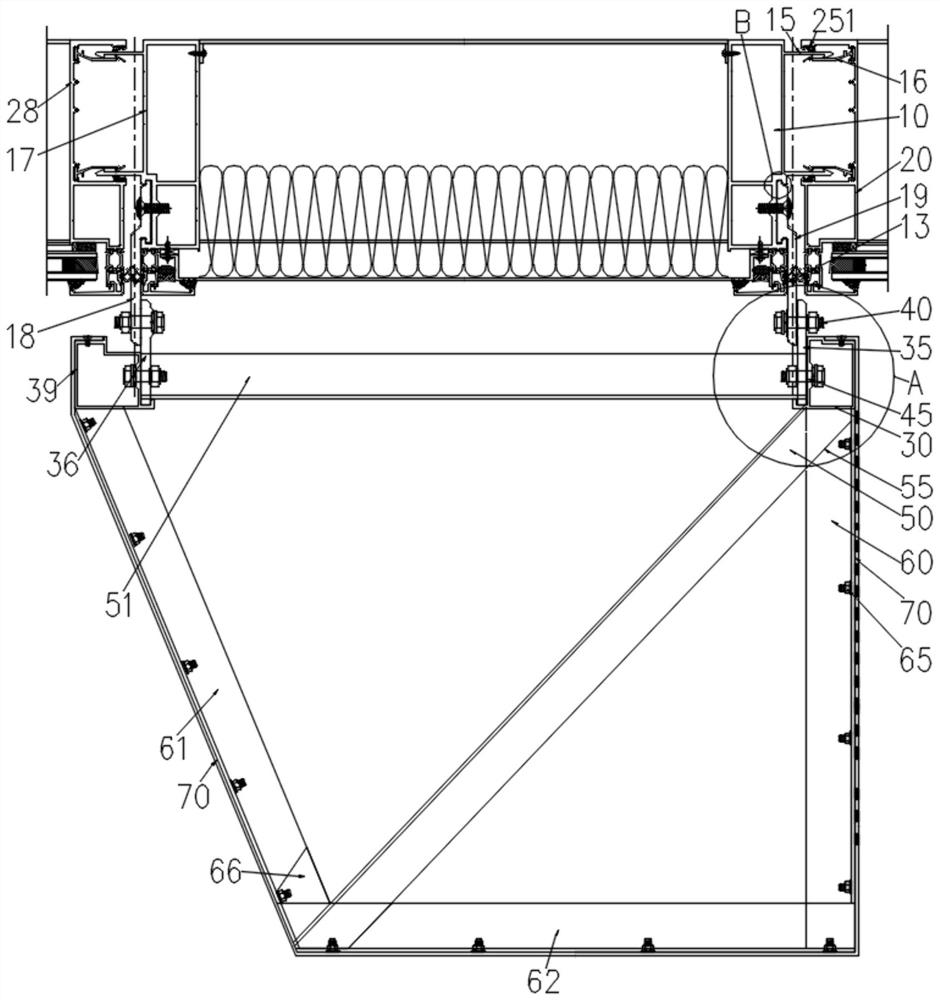

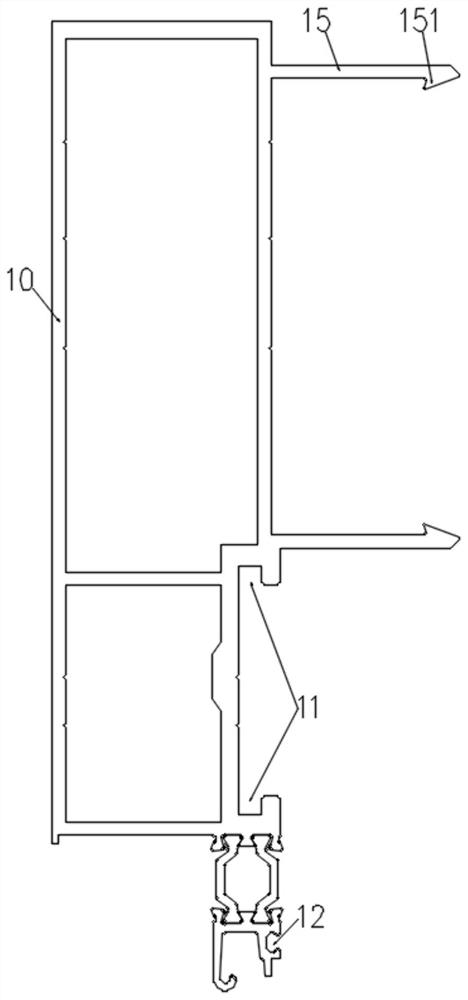

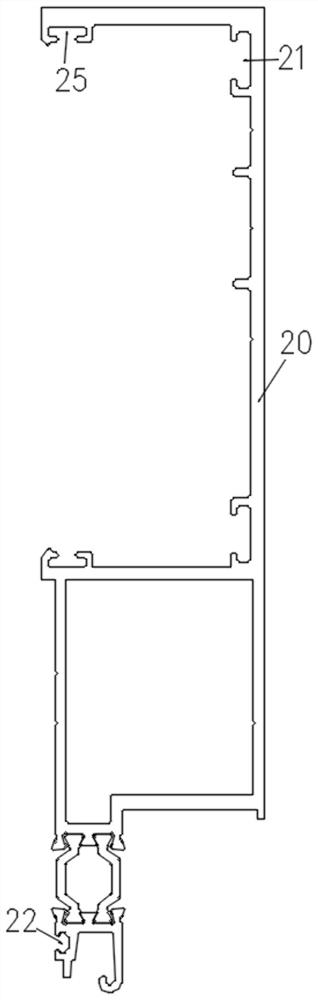

[0039] attached figure 1 To attach Figure 6 Among them, an open aluminum curtain wall system with a large aluminum structure, including a first aluminum alloy column 30, a first L-shaped aluminum angle 51, a second aluminum alloy column 39, and a second L-shaped aluminum angle 61 fixedly connected in sequence , a third L-shaped angle aluminum 62 and a fourth L-shaped angle aluminum 60, and a fifth L-shaped angle aluminum 50, a first curtain wall public column 10, a first curtain wall female column 20, a second curtain wall female Column 28 and a public column 17 of the second curtain wall. The inner walls of the fourth L-shaped aluminum angle 60 , the third L-shaped aluminum angle 62 and the second L-shaped aluminum angle 61 are respectively provided with a plurality of aluminum welding studs 65 .

[0040] The first aluminum alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com