Hydraulic impact drill bit with rolling teeth

A technology of hydraulic impact and rolling teeth, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of low drilling efficiency, aggravated thermal wear of cutting teeth, and high cost, and achieve the goal of reducing drilling costs, saving energy, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

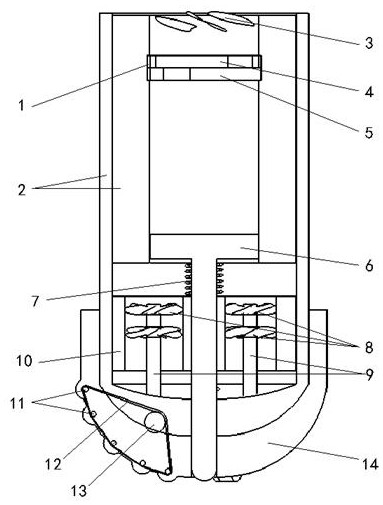

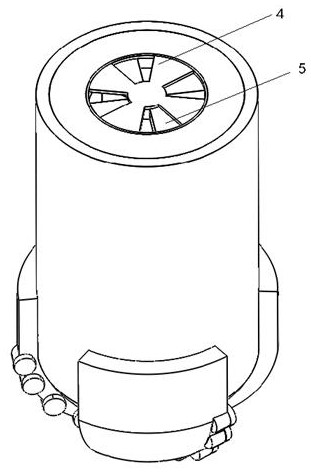

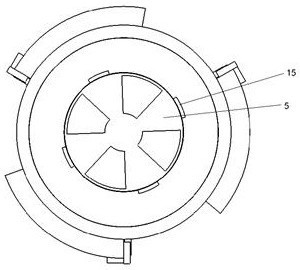

[0022] Below in conjunction with accompanying drawing, the present invention will be further described: Figure 1-Figure 8 As shown, a hydraulic percussion drill bit with rolling teeth is characterized in that the hydraulic percussion drill bit includes a turntable track 1, a drill body 2, a helical blade No. 1 3, a turntable 4, a flow limiting plate 5, an impact hammer 6, and a spring 7. Spiral blade No. 2 8, straight rod 9, hollow cavity 10, rolling teeth 11, chain 12, connecting gear 13, drill bit 14, protrusion 15, hollow bevel gear 16, sealing ring 17, water eye 18, cutting Teeth 19, bearings 20, pinion 21, large gear 22, conical teeth 23, the inner cavity of the drill body 2 is equipped with a turntable track, the turntable 4 is embedded in the turntable track 1, the upper end of the turntable 4 is connected to the screw blade No. 1 No. 3, and the lower end of the turntable 4 In contact with the restrictor plate 5, the outer wall of the restrictor plate 5 has a protrusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com