A bottom well multi-stage flow control valve

A water control valve and diverter flow channel technology, which is applied in wellbore/well valve devices, wellbore/well components, sealing/packing, etc. It can not effectively increase the oil-water flow effect, etc., so as to achieve the effect of good water control effect and good water flow control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

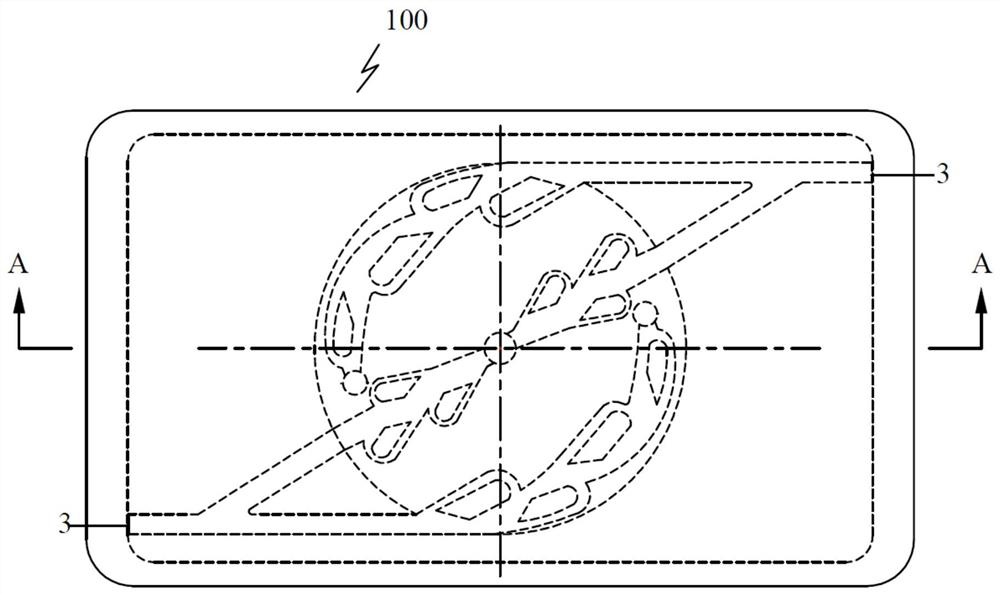

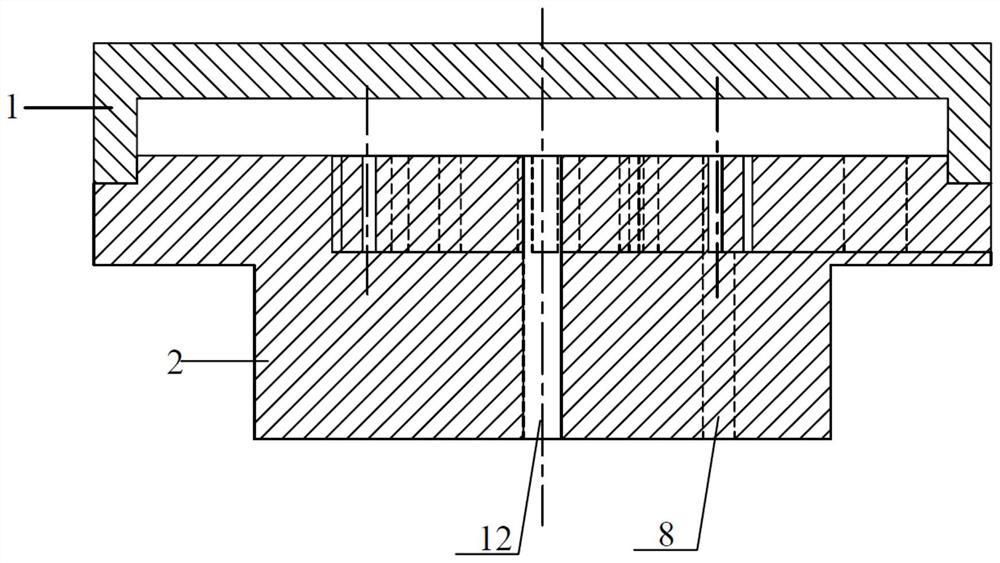

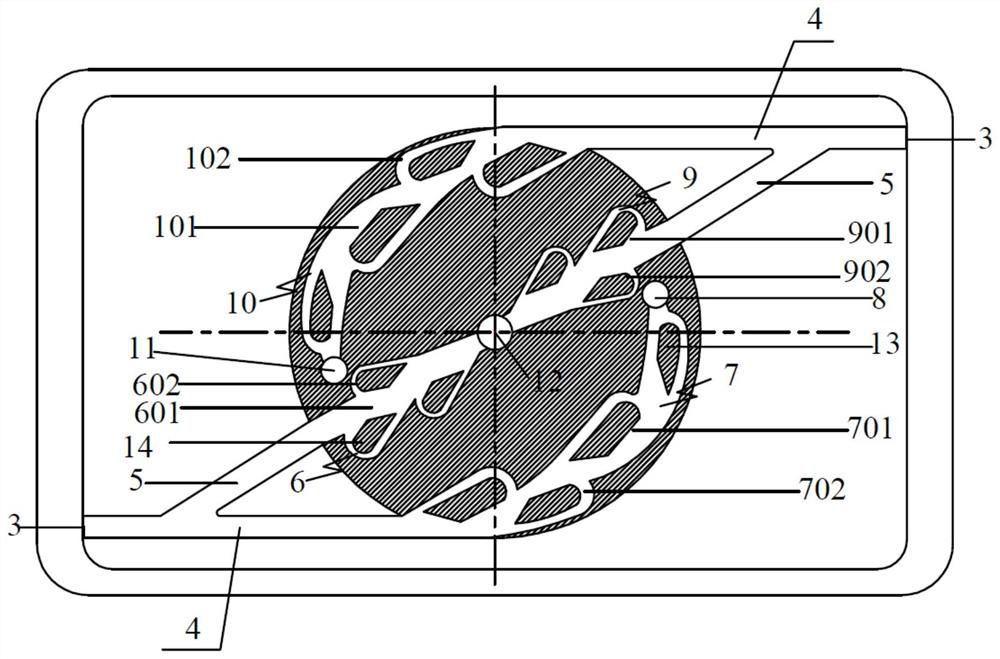

[0023] Such as Figure 1-Figure 3 As shown, the embodiment of the present invention provides a multi-stage split flow control water valve at the bottom of a well, which may include: a valve cover 1 and a valve body 2; The boss realizes the clamping and fixed connection, and has an interference fit with the valve body 2; the valve body 2 includes 2 liquid inlets 3, 3 liquid outlets 8, 11, 12, and 2 liquid inlets 3 are located on the opposite corners of the valve body On the side, the three liquid outlets 8, 11, and 12 are respectively axially connected. The center of the circular section of the liquid outlet C12 coincides with the origin of the central axis of the valve body, and the liquid outlets A8 and B11 are respectively arranged on both sides of the central axis. The liquid inlet 3 and the liquid outlet 3 are communicated through the flow passages...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com