Compressor air cylinder and compressor comprising same

A technology of compressors and cylinders, applied in the field of compressor cylinders, can solve the problems of reducing compressor efficiency, increasing compressor weight, material cost, suction loss, etc. Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]An example embodiment will now be described more fully with reference to the accompanying drawings. However, an example embodiment can be implemented in a variety of forms, and is not to be construed as being limited to the examples described herein; in contrast, the present disclosure will make the present disclosure will be more comprehensive and complete, and the concept of an example embodiment is fully conveyed A technician in the art. The features, structures, or characteristics described may be incorporated in one or more embodiments in any suitable manner.

[0043]Further, the drawings are only schematic illustrations of the present disclosure, and it is not necessarily drawn. The same reference numerals in the figure represent the same or similar portions, and thus repeats them will be omitted. Some of the block diagrams shown in the drawings are functional entities, and do not necessarily have to correspond to physical or logically independent entities.

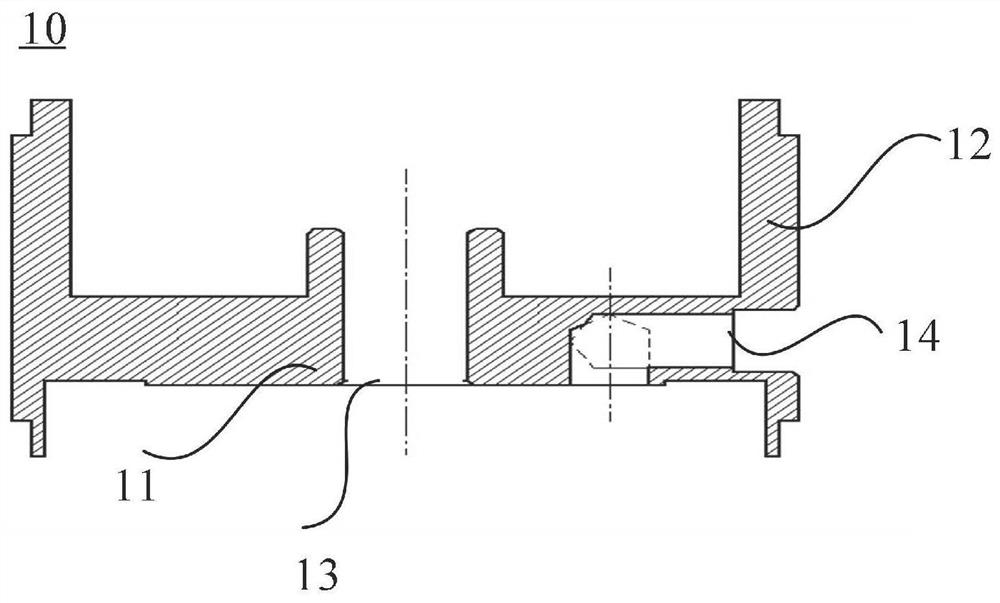

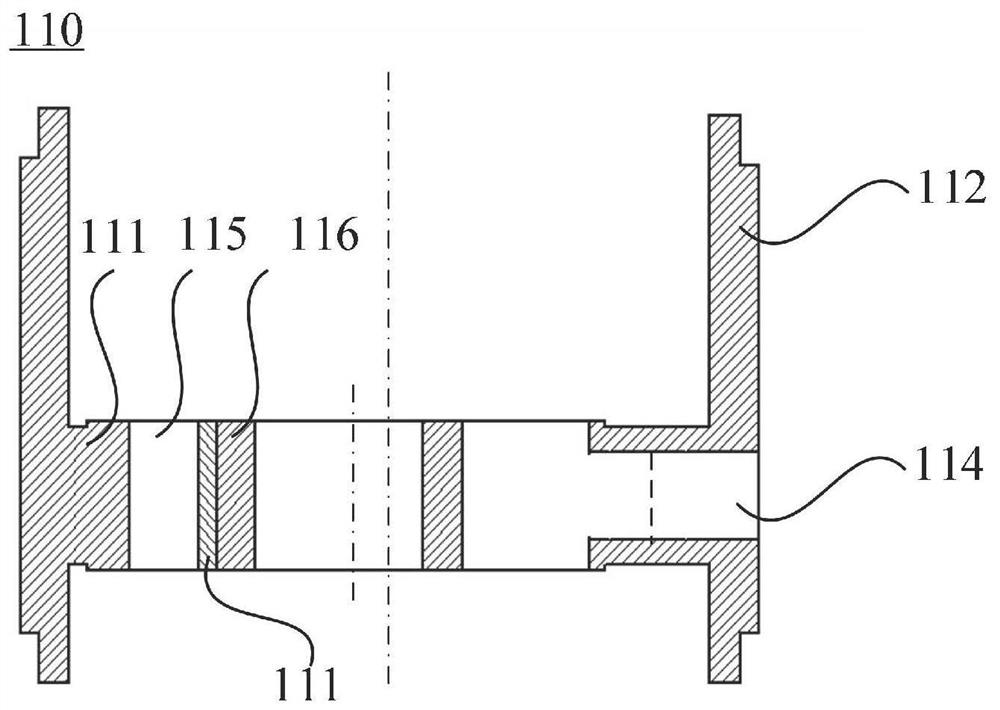

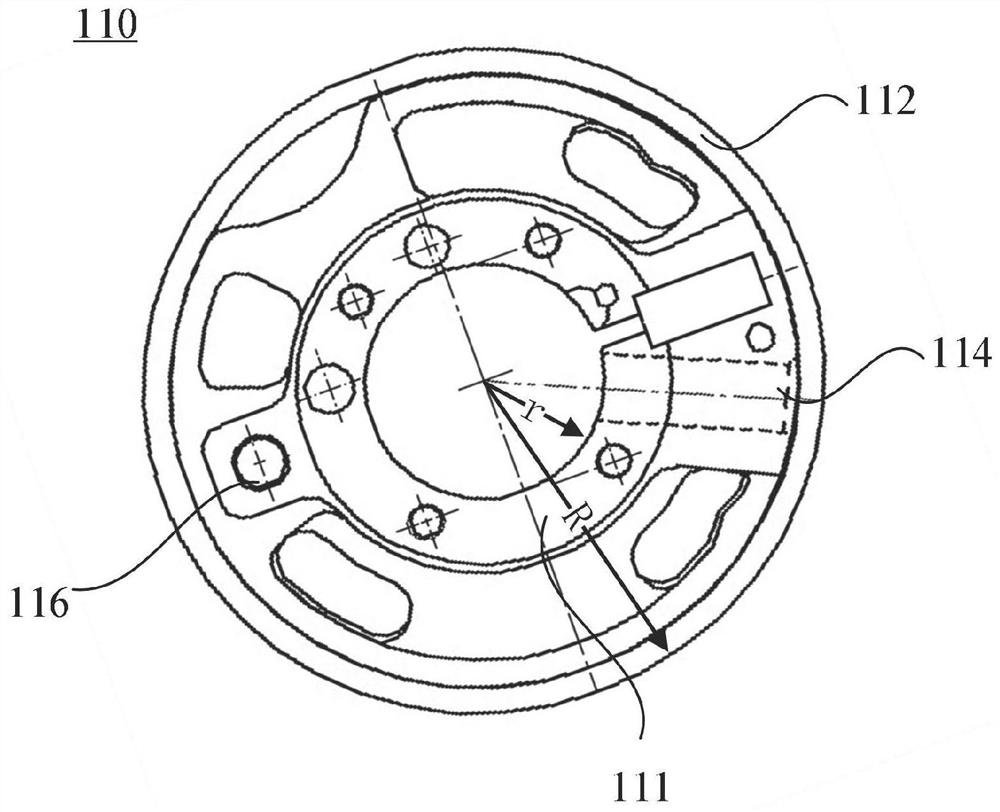

[0044]figure 2 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com