Burner and gas cooker with same

A burner, gas outlet technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as ignition time delay and affect user experience, achieve fast ignition, enhance user experience, and improve contact. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

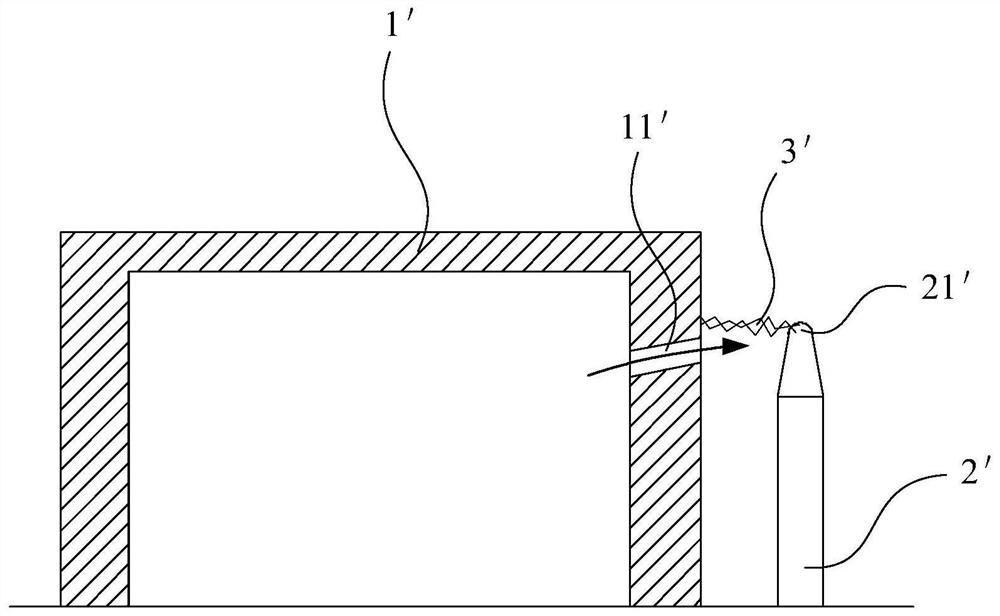

Problems solved by technology

Method used

Image

Examples

Embodiment 1

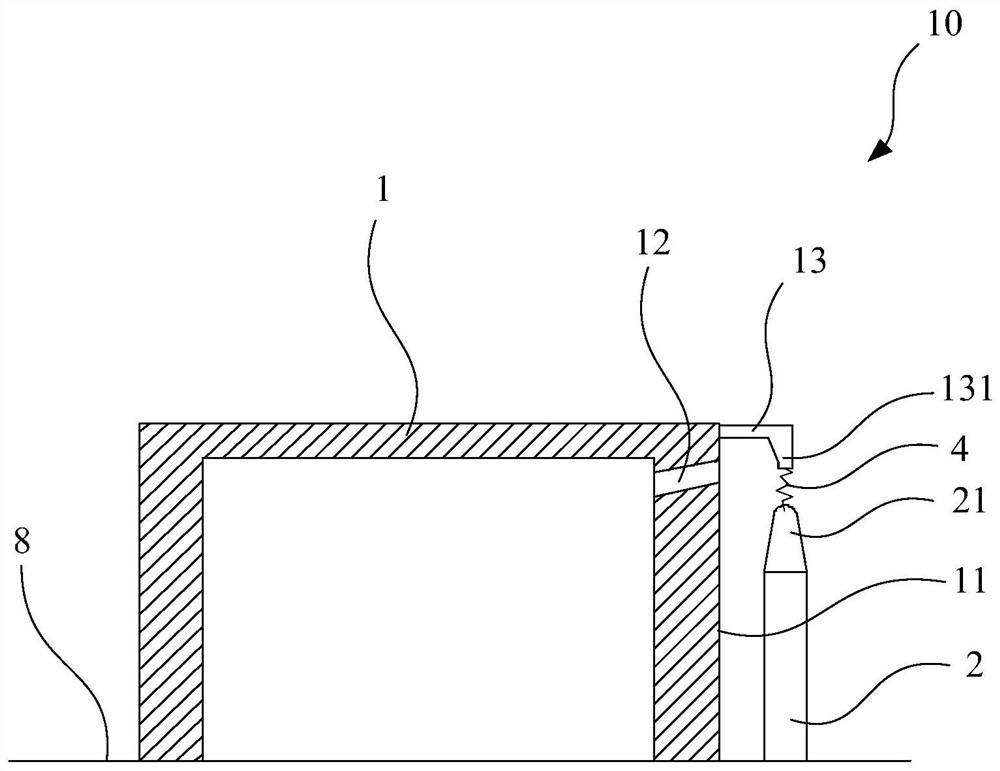

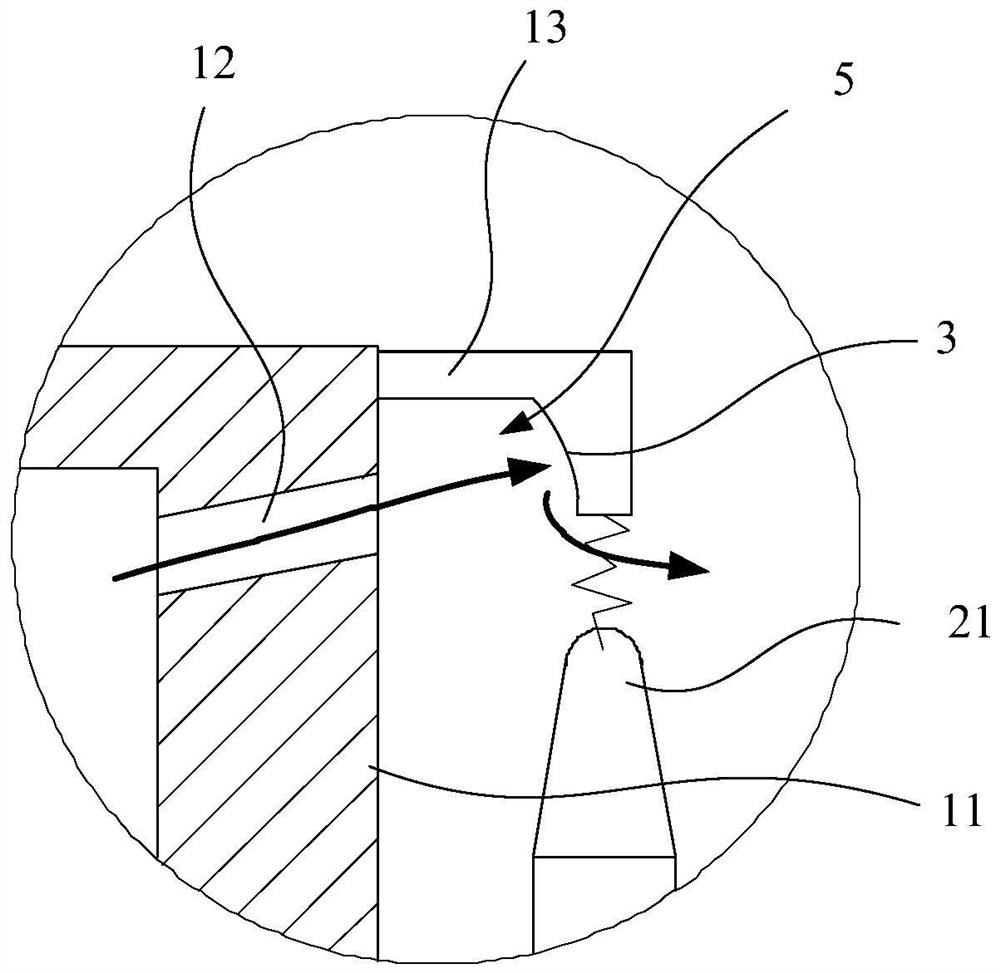

[0074] The present invention provides a gas cooker, which includes a burner 10 arranged on a cooker table 8 . Such as figure 2 As shown, the burner 10 includes a fire cover 1 and an ignition needle 2. On the surface of the fire cover 1, there is a gas outlet 12 corresponding to the ignition end 21 of the ignition needle 2, wherein the ignition end 21 is formed on the ignition needle 2. At the uppermost position, the fire cover 1 has a protruding portion 13 protruding from the outer surface 11 of the fire cover 1 above the ignition end 21, and the protrusion 13 extends to the top of the ignition end 21 along the horizontal direction, and close to the firing end 21, while, as image 3 As shown, the burner 10 also has a flow guiding structure 3 , which can guide the gas flowing out of the gas outlet 12 to flow through the area between the ignition end 21 and the protruding part 13 . In this embodiment, the flow guiding structure 3 is an arc-shaped surface formed on the protrud...

Embodiment 2

[0082] This embodiment also provides a burner 10 for a gas cooker, and the structure of the burner 10 is similar to that of the first embodiment. Specific as Figure 4-Figure 6 As shown, the burner 10 of this embodiment is an anti-dry burner, wherein the anti-dry burner specifically includes a fire cover 1 , an anti-dry sensor 6 and an energy gathering ring 9 . Wherein, the inner ring of the fire cover 1 is arranged around the anti-dry sensor 6, and the energy gathering ring 9 is arranged around the outer ring of the fire cover 1, and a pot support structure is integrated on the energy gathering ring 9.

[0083] The detection part 61 of the anti-dry heating sensor 6 is arranged higher than the inner ring top surface 17 of the fire cover 1, so as to ensure that the detection part 61 can be in contact with the bottom surface of the pot. The fire cover 1 forms a cavity 15 for accommodating the dry-burn prevention sensor 6 inside the inner ring part, and the burner 10 also includ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap