Self-washing end socket cover and heat exchange equipment

A heat exchange equipment and self-cleaning technology, applied in the field of head cover, can solve the problems of easy fouling and fouling and corrosion under scale, and achieve the effect of improving the total heat transfer coefficient, matching the heat supply coefficient and reducing the formation of fouling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

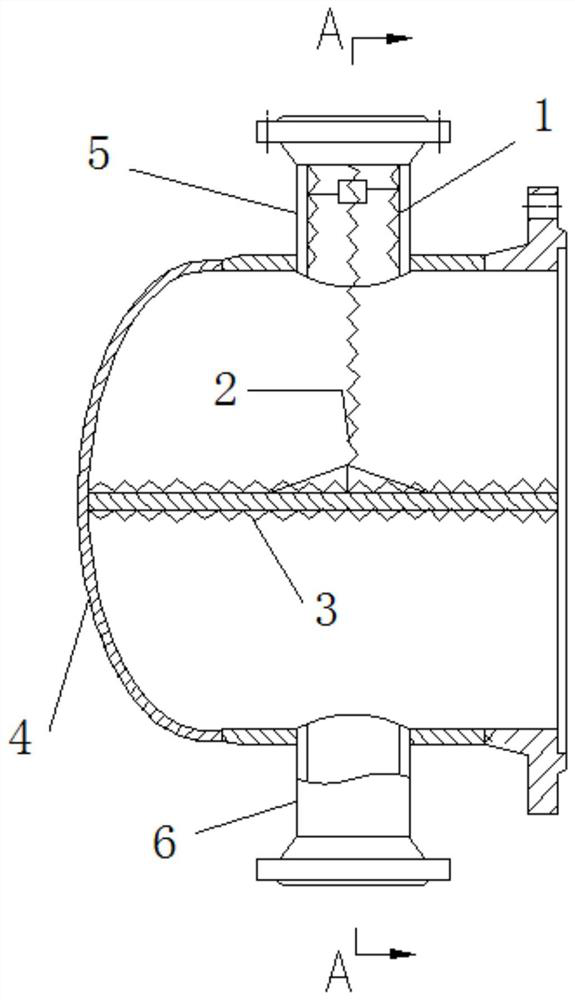

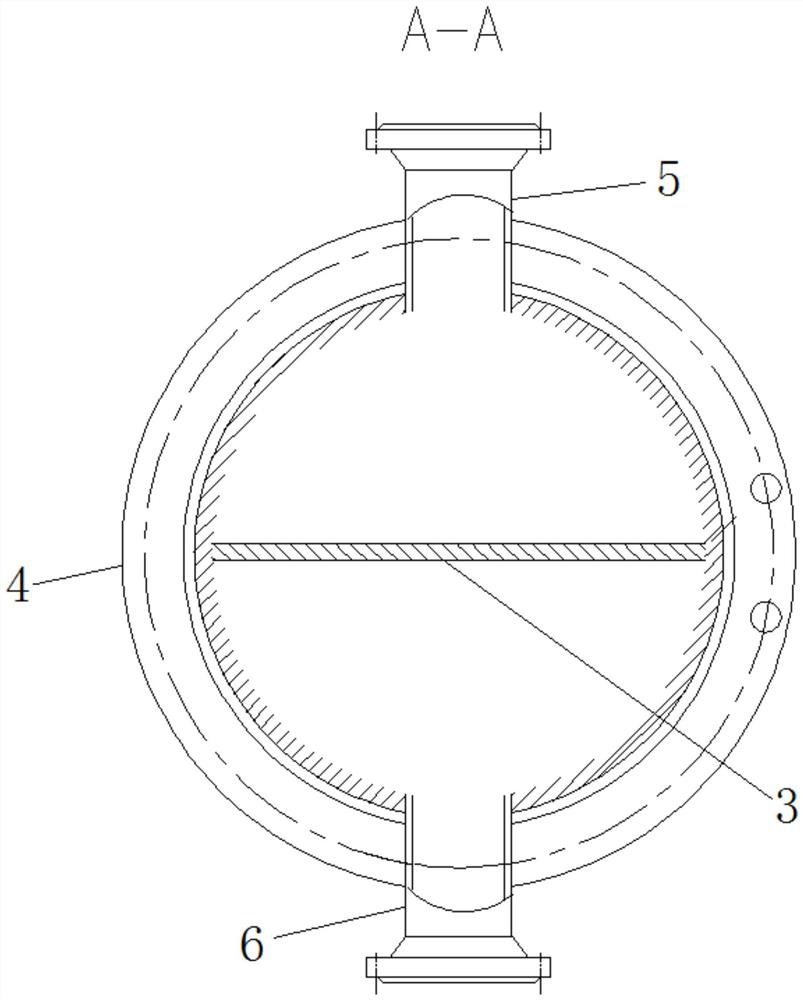

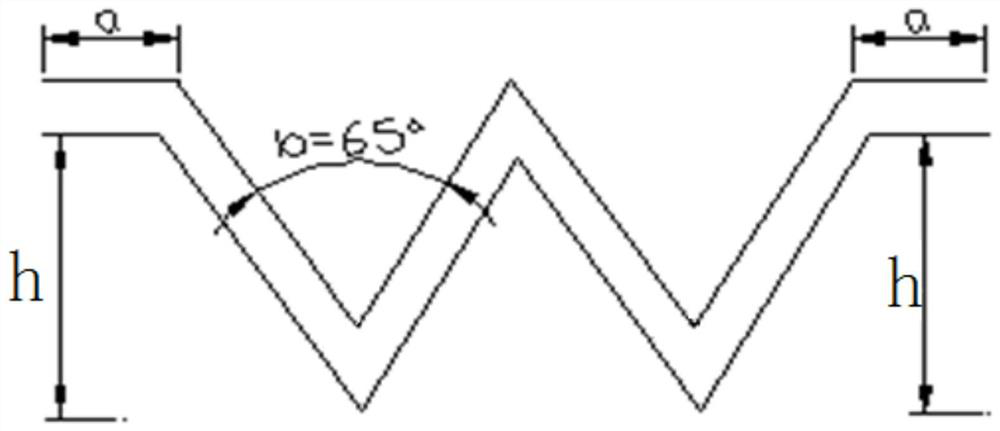

[0033] As an implementation, both ends of the second toothed tube 1 extend to the inlet and the outlet of the inlet passage 5 respectively. That is, the second toothed pipe 1 runs through the entire inlet channel 5 to make the fluid turbulent more fully.

[0034]As an embodiment, the inner wall surface of the inlet channel 5 is a tooth surface. That is, it only needs to make the wall surface contacted by the fluid entering the inlet channel 5 be the tooth surface.

[0035] The self-cleaning head cover in this application is the SH-type self-cleaning head cover, and the formation of dirt on the inside of the SH-type self-cleaning head cover needs to go through 5 stages: initiation, transportation, adhesion, aging and erosion. In the five stages of fouling formation, as long as one of the links is destroyed, the fouling process will be difficult to form. When the circulating water enters the inlet channel 5 and enters the head chamber through the second toothed tube and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com