Moving magnet type absolute position detection device and method

A technology of absolute position and detection device, which is applied in the direction of using electric/magnetic device to transmit sensing components, can solve the problems of increasing system cost, unable to meet the number distinction of multiple moving components, and complicated control system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions and implementation methods in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention.

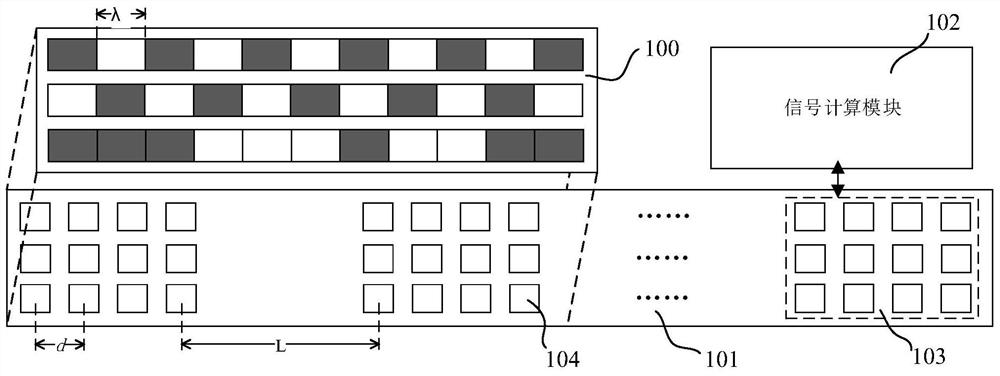

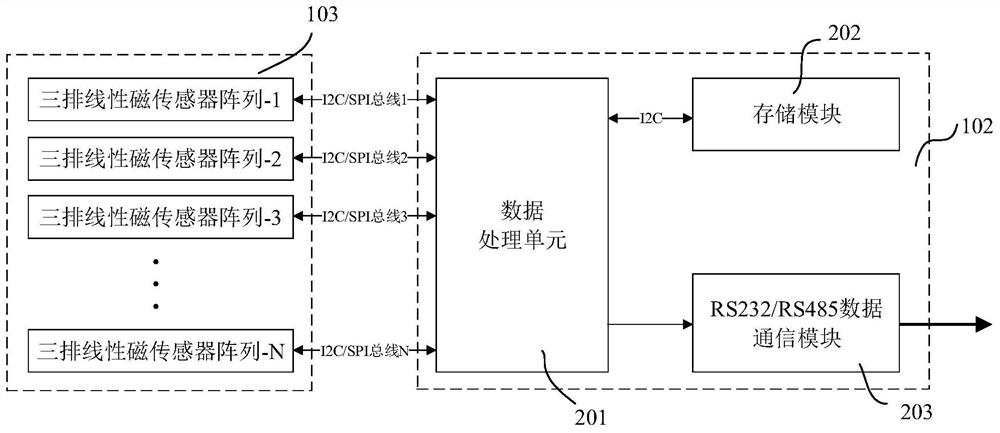

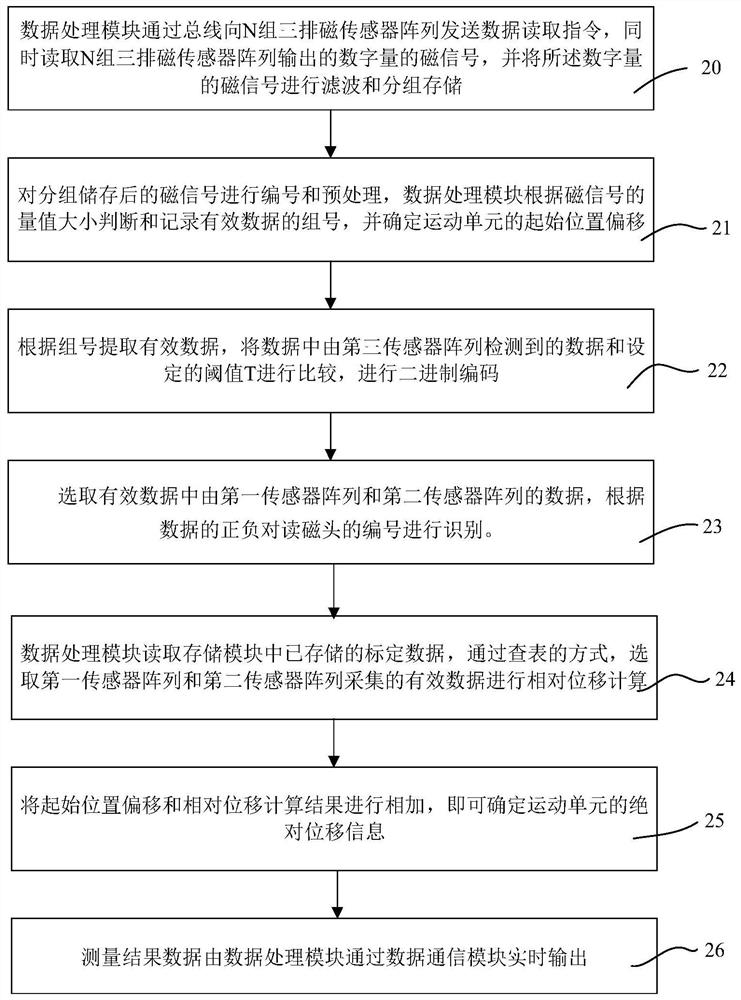

[0032] figure 1 The structural layout diagram of the example structure of the moving magnet type absolute position detection device provided by the present invention, figure 2 It is a functional block diagram of the signal calculation module in the moving magnet absolute position detection device provided by the present invention. image 3 Calculation flow chart of the moving magnet absolute displacement measurement method provided by the present invention.

[0033] A moving magnet absolute position detection device, the device in this embodiment includes a moving magnetic head 100 , a sensor acquisition board 101 and a signal calculation module 102 .

[0034] The moving magnetic head 100 is fixedly installed on the moving component to be detected for absolute dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com