High-reliability temperature sensor

A temperature sensor and reliability technology, applied in the field of sensors, can solve problems such as inaccurate data, failure of temperature sensor simulation test, and reduced reliability of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

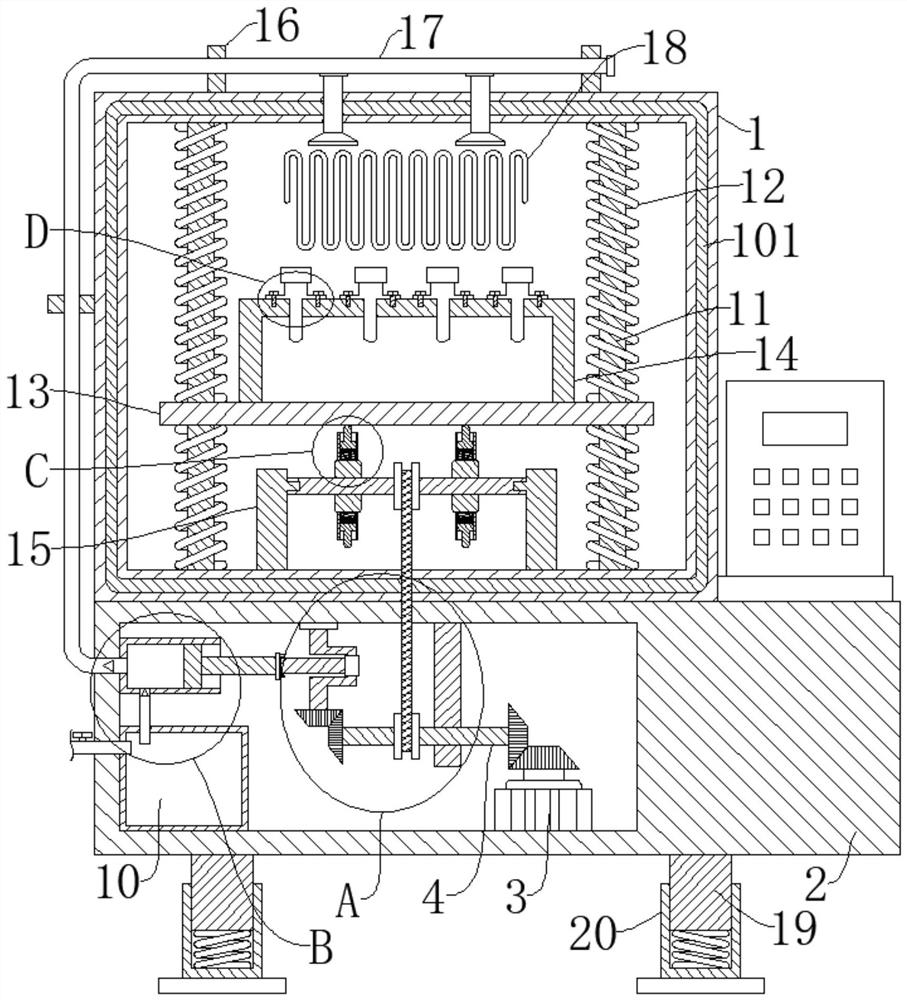

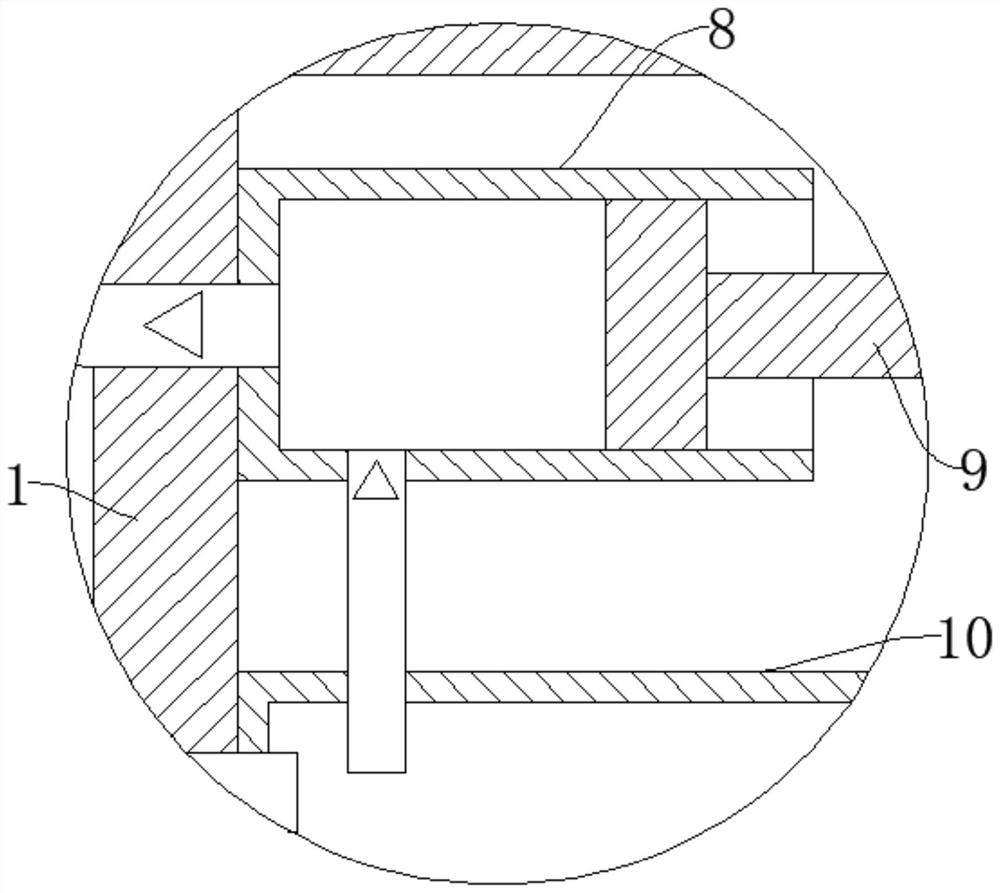

[0029] refer to Figure 1-7, a high-reliability temperature sensor, including a test box 1 and an equipment box 2, the test box 1 is fixedly connected to the equipment box 2, and two symmetrical fixed rods 11 are fixedly connected in the test box 1, and the fixed rods 11 slide A moving plate 13 is connected, and a return spring 12 is sleeved on the fixed rod 11. The two ends of the return spring 12 are respectively fixedly connected with the test box 1 and the moving plate 13. The upper end of the moving plate 13 is fixedly connected with a placement frame 14, and the placement frame 14 is detachably connected with a temperature sensor body 25 through a fixing bolt 26, an electric heating tube 18 is fixedly connected in the test box 1, and two symmetrical fixed blocks 15 are fixedly connected to the lower end of the test box 1 near the moving plate 13, two Between the fixed blocks 15, a rotating rod 21 is rotatably connected, and a plurality of sets of telescopic mechanisms ar...

Embodiment 2

[0032] refer to Figure 4 , a high-reliability temperature sensor, which is basically the same as Embodiment 1, furthermore: the telescopic mechanism includes a fixed wheel 22, a sleeve 23, and a telescopic rod 24, and the fixed wheel 22 is sleeved on the rotating rod 21, and is connected to the rotating rod The rod 21 is fixedly connected, the sleeve 23 is fixedly connected with the fixed wheel 22, the sleeve 23 is fixedly connected with a telescopic spring, the telescopic rod 24 is slidably connected in the sleeve 23, and is fixedly connected with the telescopic spring, when the user fixes the temperature When the sensor body 25, the driving mechanism drives the rotating rod 21 to rotate now, and the rotating rod 21 rotates at the moving sleeve 23 by the fixed wheel 22, and the sleeve 23 drives the telescopic rod 24 to rotate, when the driving mechanism drives the telescopic rod When 24 rotates quickly, centrifugal force will be generated, so that the telescopic rod 24 will ...

Embodiment 3

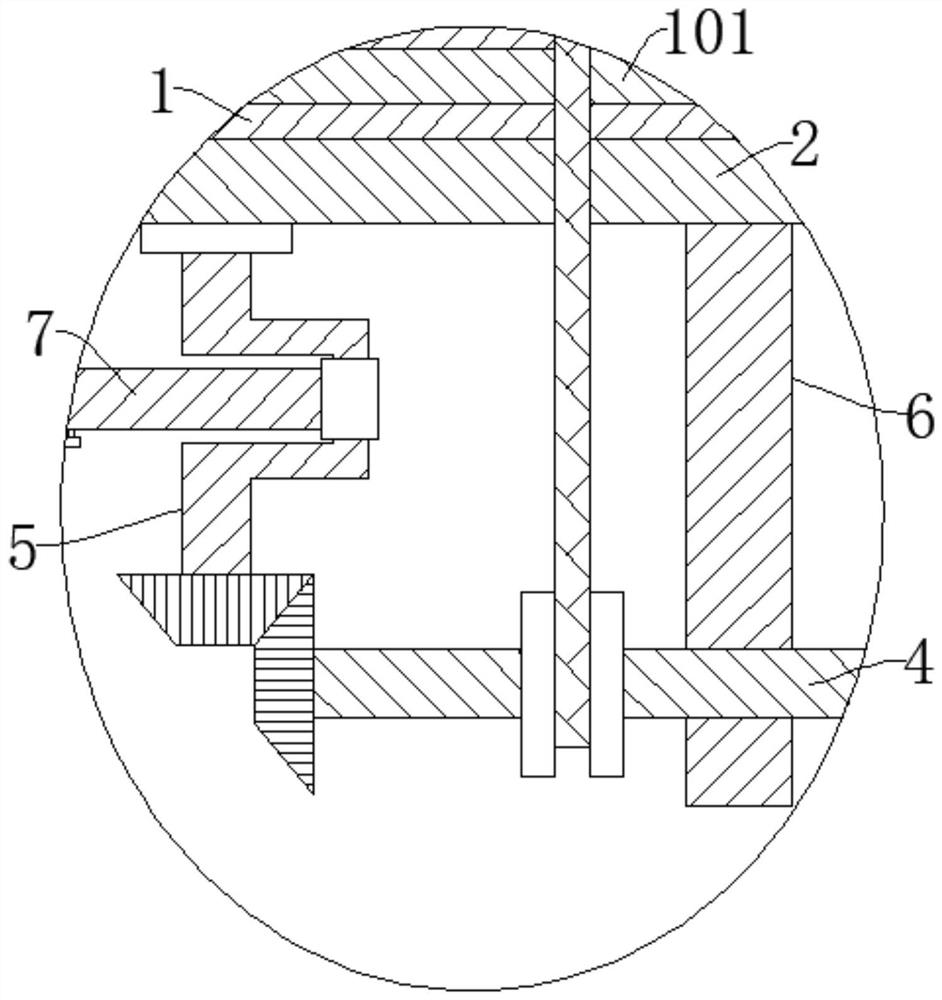

[0034] refer to Figure 1-2 , a high-reliability temperature sensor, which is basically the same as Embodiment 1, furthermore: the driving mechanism includes a motor 3, a first output shaft 4, a fixed plate 6, a second output shaft 5, and the motor 3 and the fixed plate 6 are all Fixedly connected in the equipment box 2, the first output shaft 4 is rotatably connected to the fixed plate 6, the second output shaft 5 is rotatably connected in the equipment box 2, the output end of the motor 3 is fixedly connected with the first bevel gear, the first output One end of the shaft 4 close to the motor 3 is fixedly connected with a second bevel gear matching the first bevel gear, the end of the first output shaft 4 away from the motor 3 is fixedly connected with a third bevel gear, and the second output shaft 5 is fixedly connected with a The fourth bevel gear matched with the third bevel gear, the first output shaft 4 is fixedly connected with the second runner, the first runner and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com