Online service life monitoring system for low-voltage conductors of three-phase alternating-current submerged arc furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

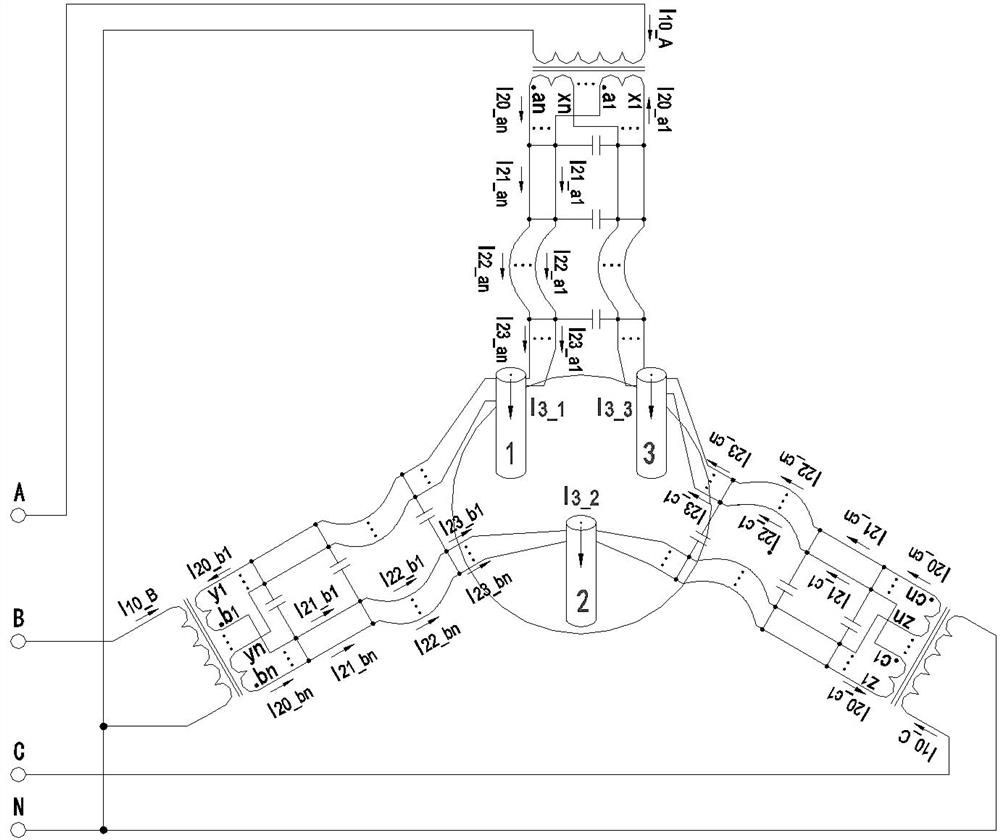

[0033] A three-phase AC submerged arc furnace low-voltage conductor online life monitoring system, the monitoring system includes the following monitoring steps:

[0034] Step 1) Monitor the currents of all the parallel conductors of each conductive section on the low-voltage side of the submerged arc furnace to obtain vector current signals;

[0035] Step 2) Input the vector current signal and conductor design / actual measurement parameters into the control processor;

[0036] Step 3) The control processor passes the corresponding vector correlation and space timing algorithm according to the received signal parameters, and through the inspection of the conductor material and structure expert system, judges the conductor accident and early warning, obtains the life trend and the inspection and maintenance reminder cycle.

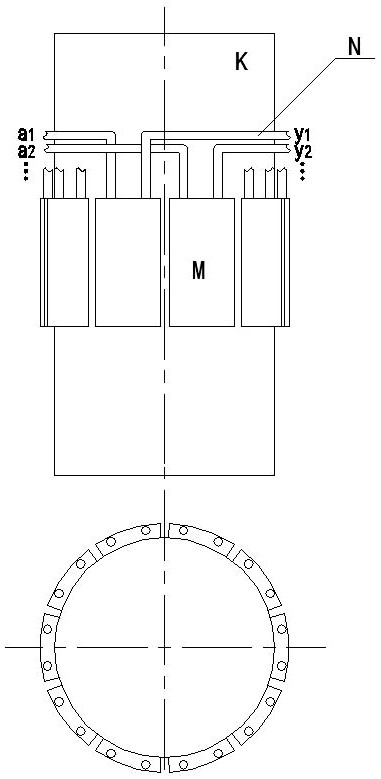

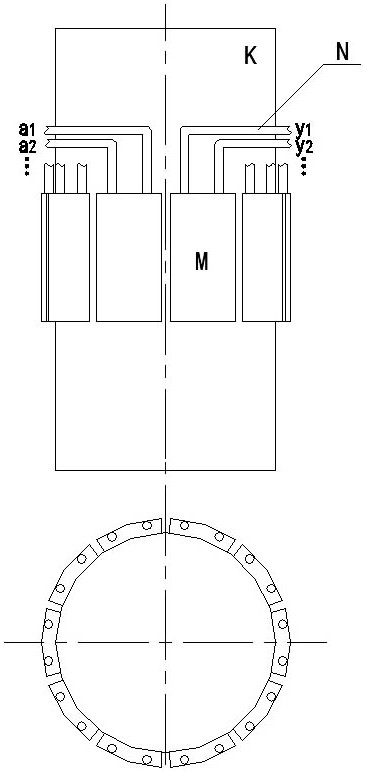

[0037] In the step 1), first build the monitoring system low-voltage short network: such as figure 1 As shown, each electrode K is connected end-to-end in ...

Embodiment 2

[0048] Implementation of water-cooled cable conductor (current) monitoring

[0049] The implementation of water-cooled cable conductor (current) monitoring is basically the same as that of electrode conductor (current) monitoring, the difference is that the Rogowski coil is installed at the front end of the water-cooled cable, and the current does not need to be synthesized; the integral processor and control processor are also installed in the box , Man-machine interface and other independent installations, can be installed on the box or in an easy-to-observe place.

Embodiment 3

[0051] The Implementation of Monitoring the Secondary Side Coil Conductor (Current) of Furnace Transformer

[0052] The implementation of the secondary side coil conductor (current) monitoring of the furnace transformer is basically the same as that of the electrode conductor (current) monitoring, the difference is that the Rogowski coil is installed at the front end of the water-cooled cable, and the current does not need to be synthesized; Installed in the box, the human-machine interface and other independent installations can be installed on the box or in a place that is easy to observe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com