Punching-resistant concrete-filled steel tube column foot structure and punching-resistant capacity estimation method thereof

A steel tube concrete column, anti-punching technology, applied in the direction of foundation structure engineering, columns, pier columns, etc., can solve the problems of thick protruding rafts, complex waterproof construction of formwork, etc., to improve the anti-punching ability, reduce The effect of concrete dosage and thickness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

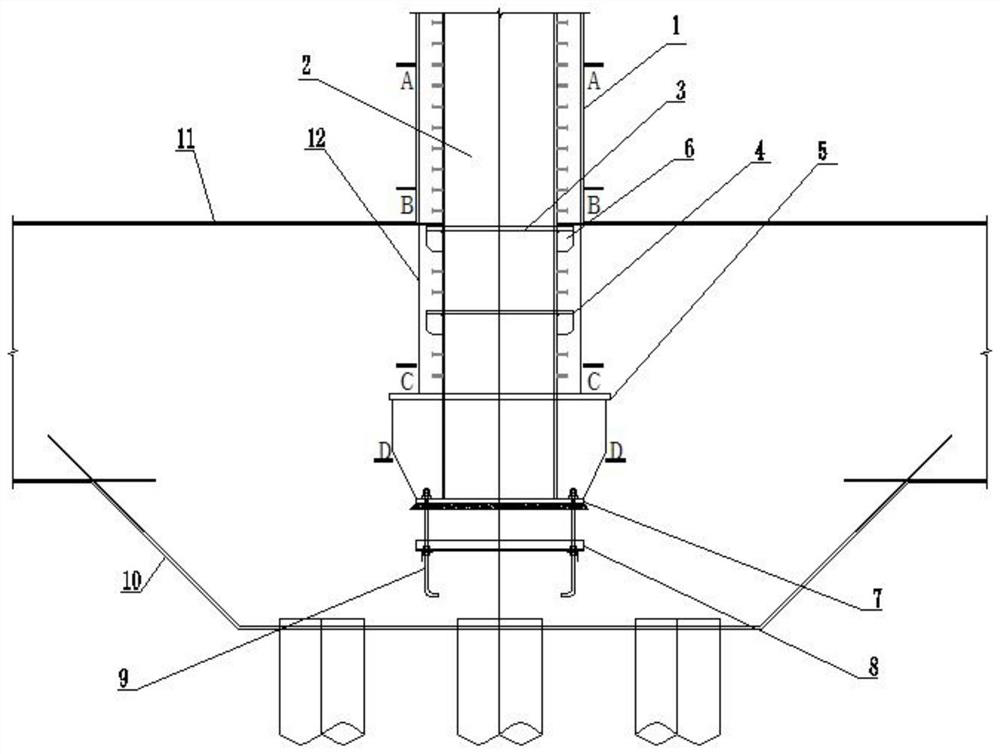

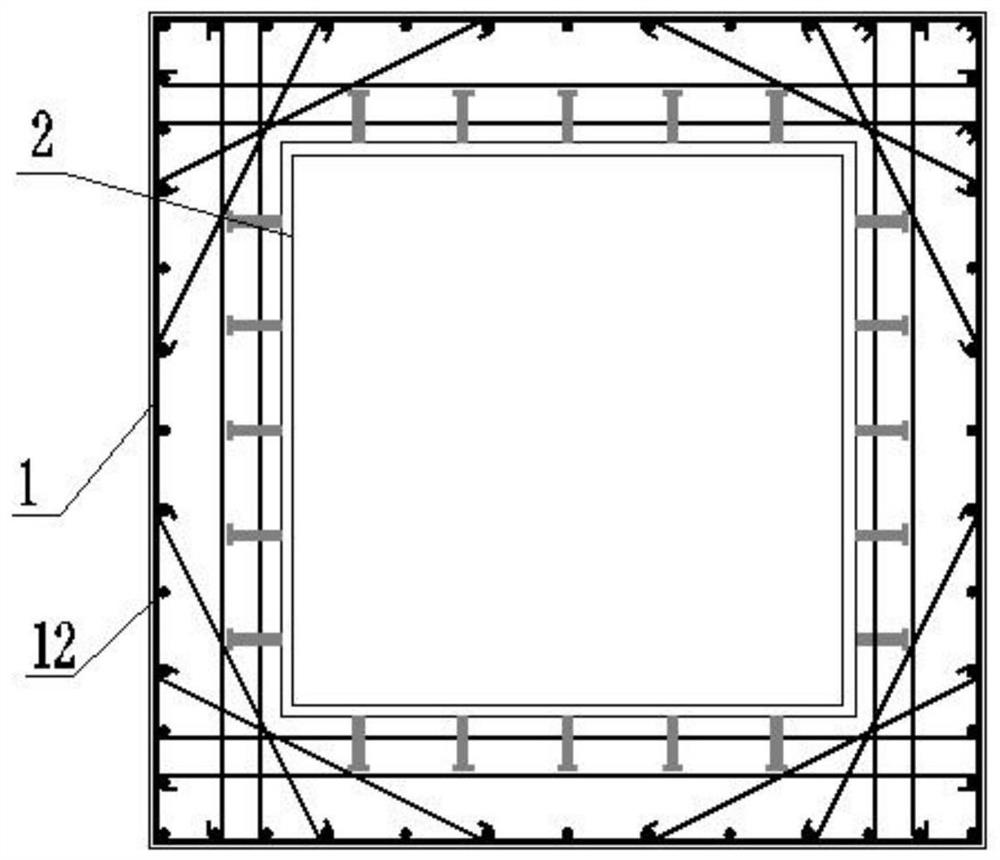

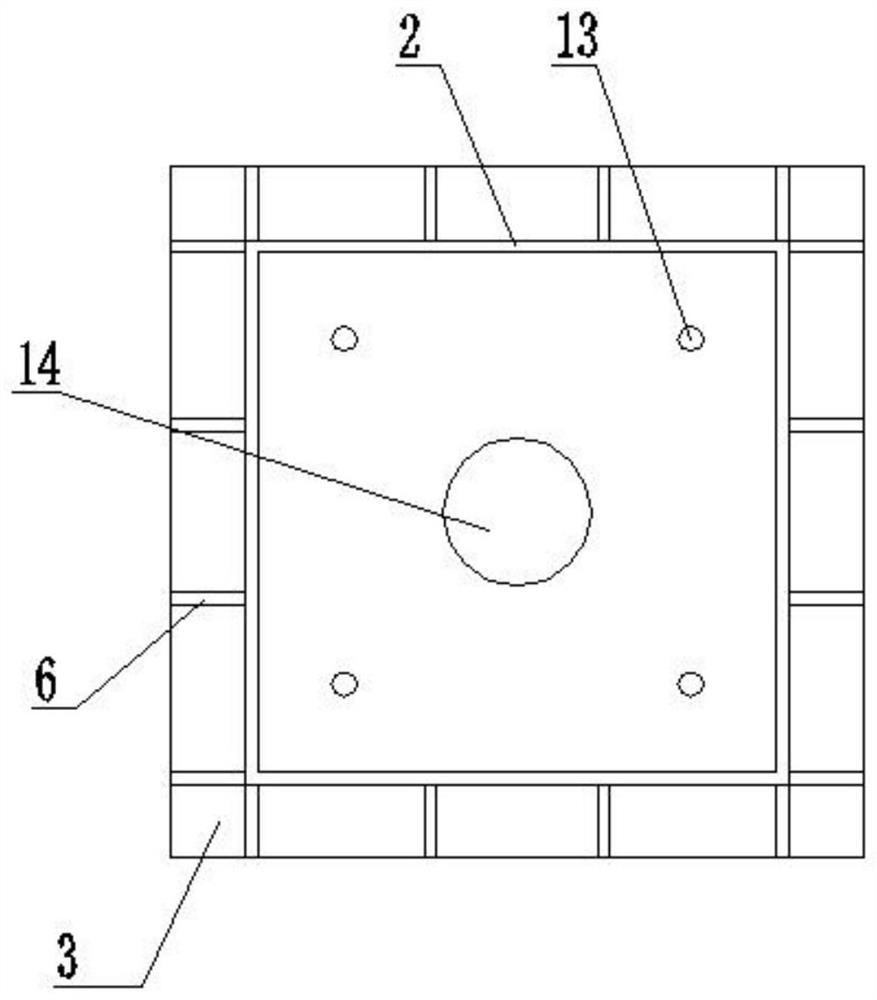

[0077] The punching-resistant concrete-filled steel tube column base structure in the super high-rise building of this embodiment includes the first punching-resistant ring plate 3, the second punching-resistant ring plate 4 and the third anti-punching ring plate arranged along the steel tube concrete column 1 from top to bottom. Punching ring plate 5, wherein the radial width of the first punching-resistant ring plate 3 and the second punching-resistant ring plate 4 is smaller than the radial width of the third punching-resistant ring plate 5; the first punching-resistant ring plate 3 and the second anti-punching ring plate 4, the distance L2 between the second anti-punching ring plate 4 and the third anti-punching ring plate 5, and the distance between the third anti-punching ring plate 5 and the bottom of the column foot The distance L3 between the plates 7 and the distance L4 between the bottom plate 7 of the column foot and the bottom of the concrete foundation 10 satisfy:...

Embodiment 2

[0095] In this example, the axial tensile force N b It is 14000kN, the cross-sectional size of the steel pipe 2 columns is 1100mm*1100mm*30mm, the strength grade of the outsourcing and inner pouring concrete are both C60, the concrete outsourcing size is 250mm, the longitudinal reinforcement is 48C32, the first punching shear ring plate 3, the second anti The lengths of the punching ring plate 4 , the third punching-resistant ring plate 5 and the column base plate 7 are 150mm, 150mm, 500mm and 250mm respectively.

[0096]When the steel tube concrete column 1 bears the tensile force, multiple stacked anti-punching shear surfaces are formed on the multiple punching-shearing ring plates and the column base plate 7; The punching resistance is calculated by the following formula:

[0097] A s =1100 2 -1040 2 =128400mm 2

[0098] A s1 =48×804=38592mm 2

[0099]

[0100] A 2 =1400 2 -1100 2 =750000mm 2

[0101] A 3 =2100 2 -1100 2 =3200000mm 2

[0102] A 4 =160...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com