IGBT press-fitting structure

A press-fit structure and pressure-receiving plate technology, which is applied in the direction of transforming equipment structural parts, emergency protection circuit devices, output power conversion devices, etc., can solve the problems of poor operation stability of DC fault ride-through capability, achieve compact structure, improve The effect of stable operation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058]The present invention will be further described in detail below with reference to the accompanying drawings.

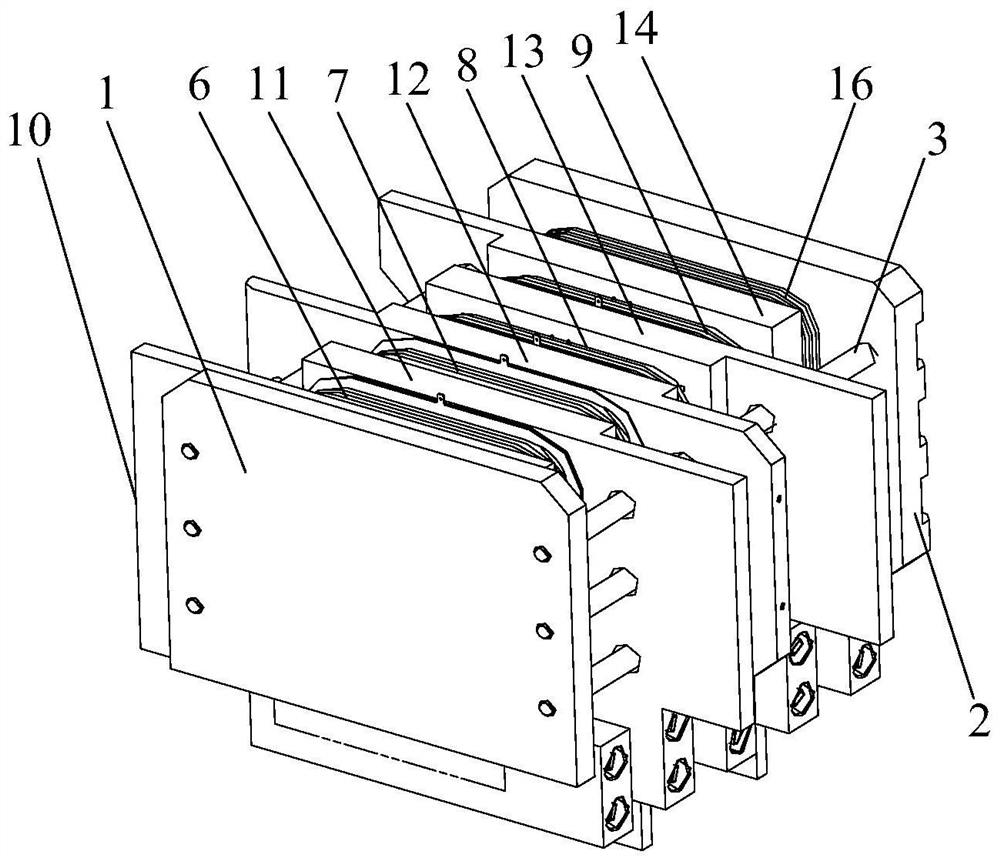

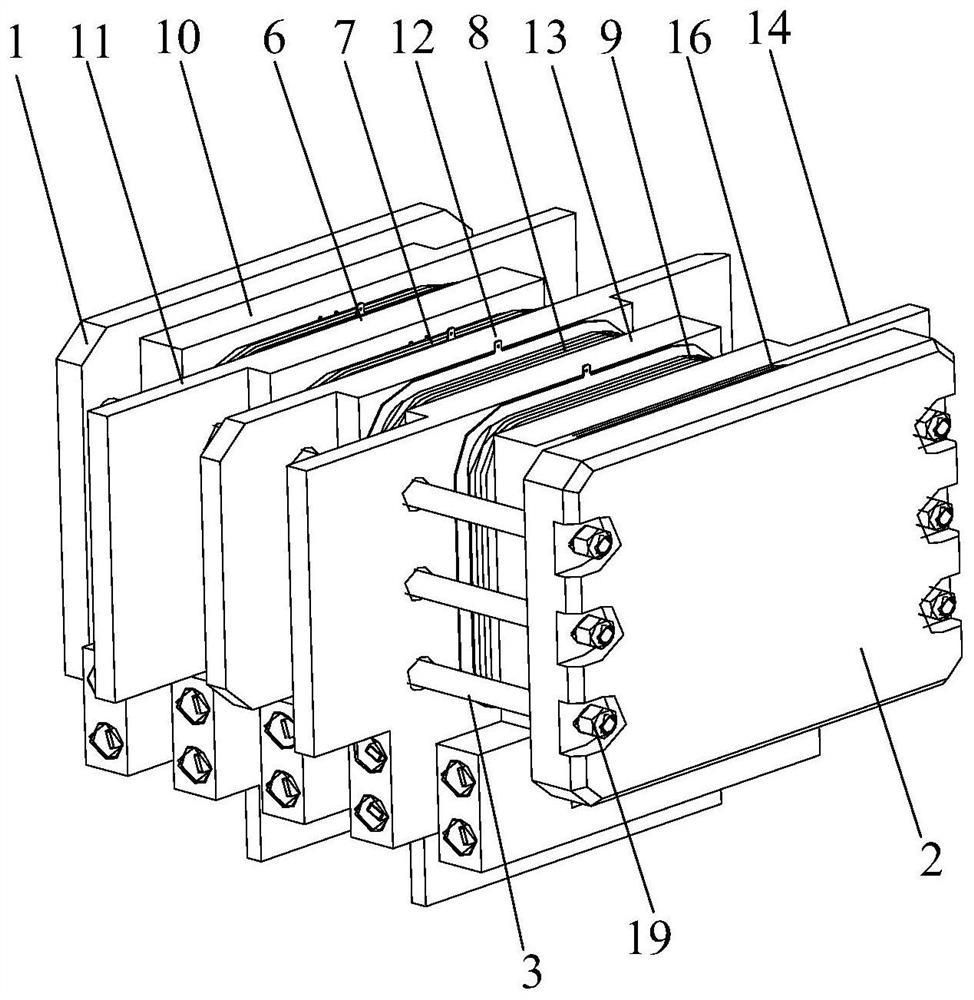

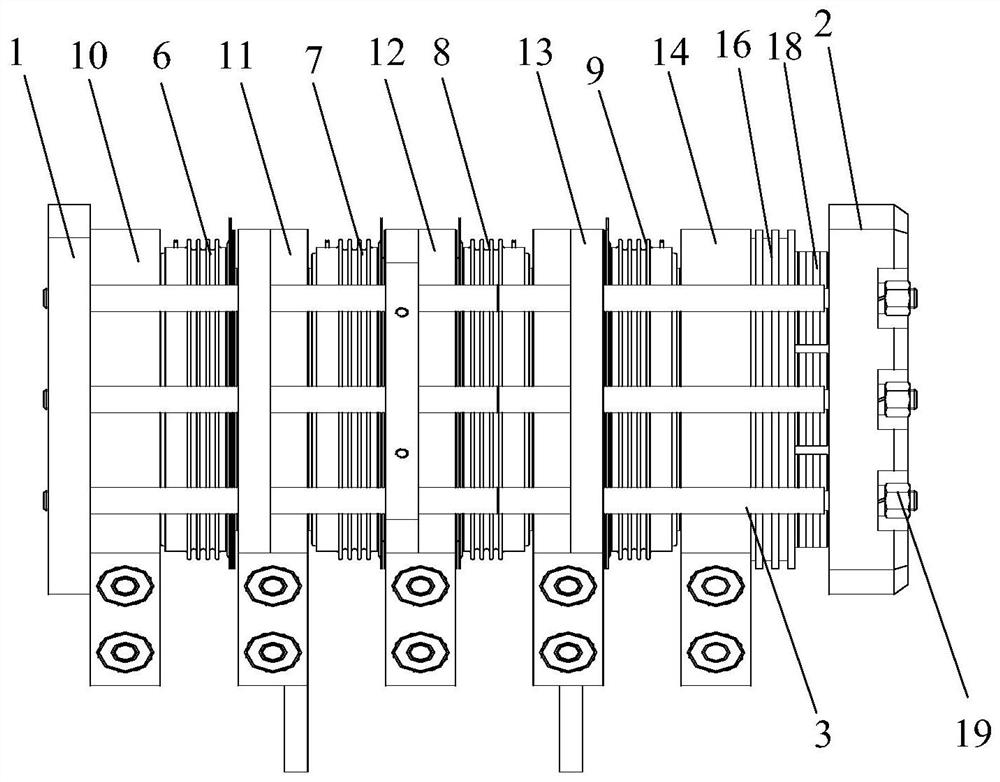

[0059]Embodiments of the present invention provide an IGBT press structure, including IGBT components, radiator components, and support components;Figure 1 - Figure 4As shown, the support assembly includes a first end plate 1, a second end plate 2, and a tie rod assembly; the first end plate 1 and the second end plate 2 are arranged in parallel, and both ends of the tie rod assembly are respectively connected to the first end plate 1 and the second. The end plate 2 is fixed, that is, one end of the tie rod assembly is fixed to the first end plate 1 by the thread, and the other end of the tie rod assembly passes through the through hole of the second end plate 2, and then the nut 19 is fastened. The first end plate 1, the second end plate 2, and the tie rod assembly form a housing space; the IGBT assembly and the heat sink assembly are disposed inside the accommodating sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com