Preparation method of set meal box capable of being stored at normal temperature

A technology of room temperature preservation and box lunch, applied in the fields of food preservation, food science, application, etc., can solve the problems of short preservation period, unsuitable for room temperature preservation, loss of nutrients, etc., and achieve the effect of being convenient to carry and saving container and packaging materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

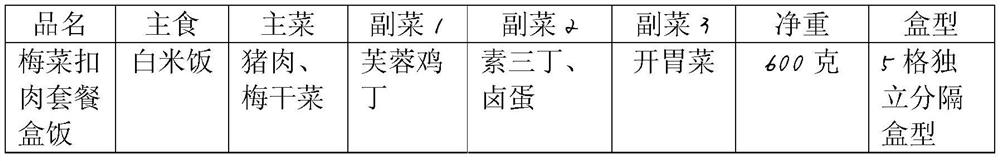

[0047] Example 1. Preparation of rice set meal with preserved vegetables and braised pork

[0048] Packing ratio:

[0049]

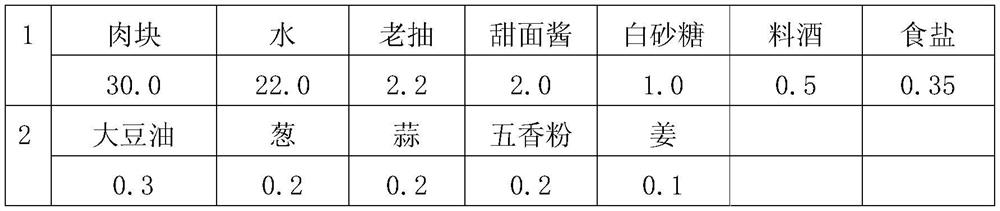

[0050] 1.1 Production of the main dish: pickled pork with pickled vegetables:

[0051] 1.1.1 Pork belly processing

[0052] (1) Choose refined pork belly with a fat-to-lean ratio of 3:7 (the total thickness of the fat does not exceed 2cm), cut into 5-6cm wide and 0.8cm thick meat pieces, and set aside.

[0053] (2) Put water in the pot, put the meat pieces into the pot, and start to heat the cold water. At most, 150kg of raw materials will be discharged from each pot, and the floating foam will be removed. After the meat pieces are completely cooked, remove them and put them in the turnover basket for later use .

[0054] 1.1.2 Dried plums and bamboo shoots

[0055] (1) Dried plum vegetables processing

[0056] Select high-quality dried plum vegetables, pick them out, remove inedible impurities, then soak them in clean water for 1-3 hours, then w...

Embodiment 2

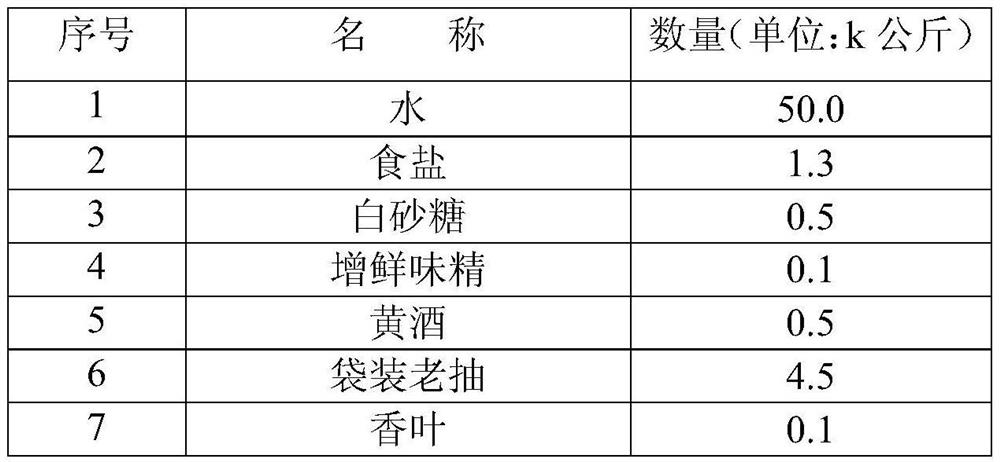

[0117] Embodiment 2. Braised beef set noodles making

[0118] Packing ratio:

[0119]

[0120] 2.1 The main dish - braised beef production:

[0121] 2.1.1 Raw material handling:

[0122] (1) Onion treatment: remove the old bark, rhizomes, shriveled parts, spots, rot and other parts, then clean them, cut them into 2-3cm onion slices, and set aside.

[0123] (2) Ginger: Wash it separately, remove the unusable part, and grind it into 0.2-0.3cm-sized powder with a slicer.

[0124] (3) Peeled garlic heads: Wash them and grind them into 0.2-0.3cm-sized pieces with a meat grinder.

[0125] (4) Treatment of potatoes: wash and remove soil, peel, cut into hob blocks with a length of about 1.5-1.8cm and a weight of about 7g / piece, soak the cut potatoes in water. The maximum water output from the potatoes is 60kg each time. Put 1.5 times the water of the potatoes in the steam pot. After the water boils, pour the potato pieces into the pot. After boiling again, keep it for 3 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com