Agricultural extrusion type garlic granule stripping device

A peeling device and extrusion technology, which is used in the separation, application, and separation of solids from solids by air flow, which can solve the problem of incomplete squeezing of garlic cloves, inability to realize automatic material control, and inability to realize automatic discharge problem, to achieve the effect of air sieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

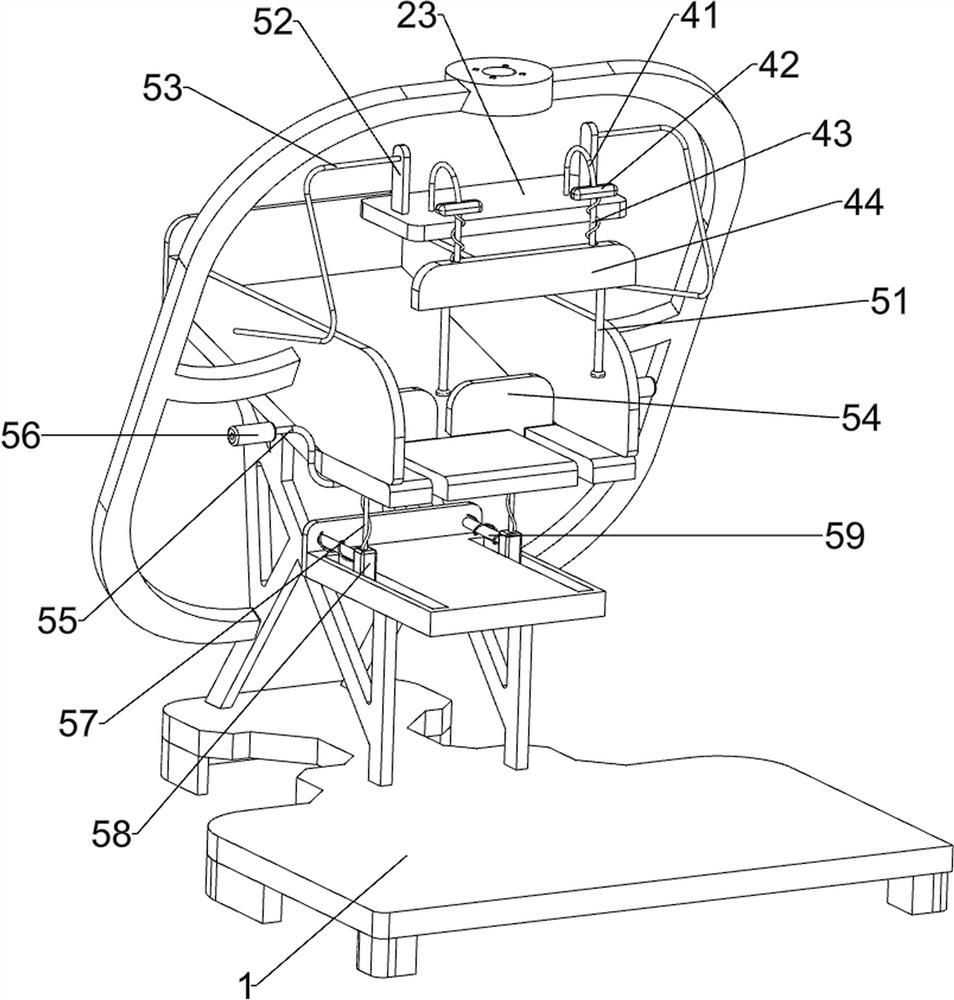

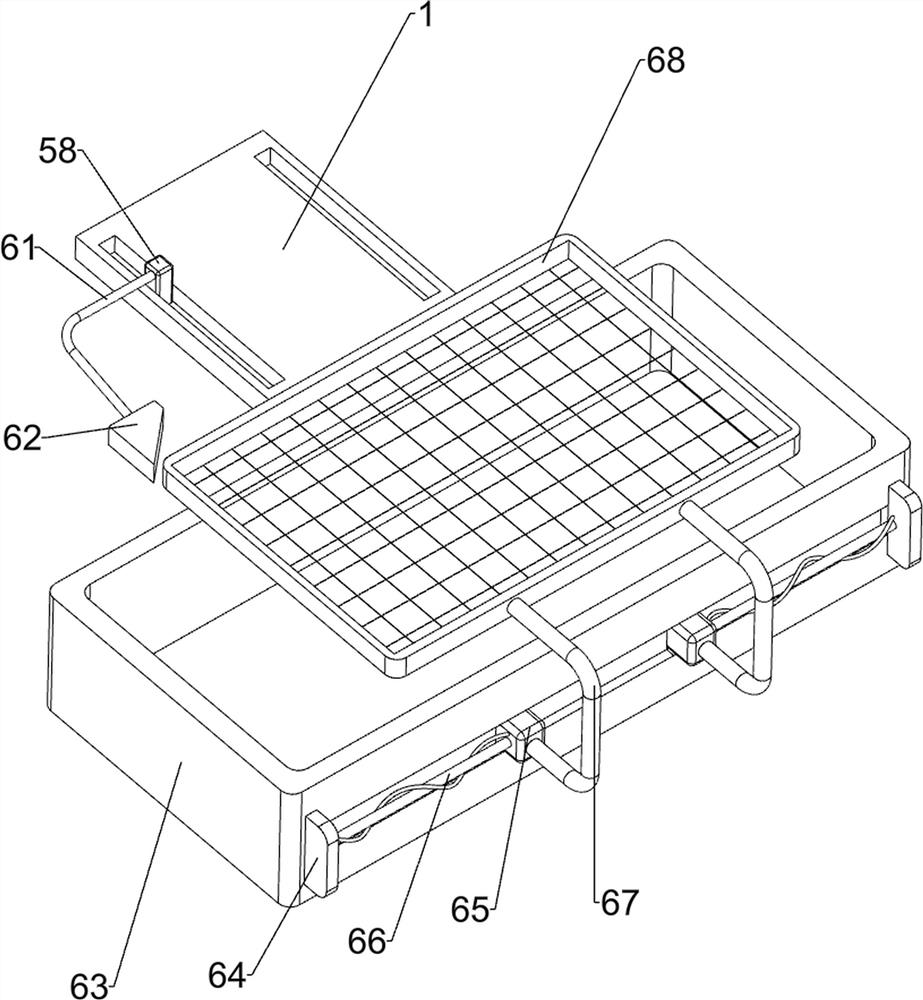

[0068] A kind of agricultural extrusion type garlic peeling device, such as figure 1 As shown, it includes a base 1, an extrusion mechanism 2 and a material control mechanism 3, and the base 1 is provided with an extrusion mechanism 2 and a material control mechanism 3.

[0069]When people want to peel off the garlic granules, they can use this agricultural squeezing garlic granule peeling device. First, the user pours the garlic cloves into the base 1, starts the squeezing mechanism 2, and the squeezing mechanism 2 moves downward. , the extrusion mechanism 2 drives the material control mechanism 3 to move backward, so that the material control mechanism 3 opens the discharge port on the base 1, and the garlic cloves fall from the discharge port on the base 1 to the bottom of the extrusion mechanism 2, and squeeze the The pressing mechanism 2 squeezes the garlic cloves, and squeezes the garlic cloves into garlic granules. After the garlic cloves are squeezed, the squeezing mec...

Embodiment 2

[0071] On the basis of Example 1, as figure 2 and image 3 As shown, the extrusion mechanism 2 includes a cylinder 21, a push block 22 and a pressure plate 23, a cylinder 21 is installed on the front side of the base 1, a push block 22 is connected to the bottom end of the telescopic rod of the cylinder 21, and a pressure plate 23 is provided at the bottom of the push block 22 .

[0072] The user pours the garlic cloves into the base 1, activates the air cylinder 21, the telescopic rod of the air cylinder 21 extends downward, and the telescopic rod of the air cylinder 21 drives the push block 22 to move downward, thereby driving the pressure plate 23 to move downward, and the pressure plate 23 contacts the garlic cloves, The pressing plate 23 is made to squeeze the garlic cloves, and the garlic cloves are squeezed into garlic granules to achieve the squeezing effect. After the garlic granules are squeezed, the telescopic rod of the cylinder 21 is controlled to shorten upward...

Embodiment 3

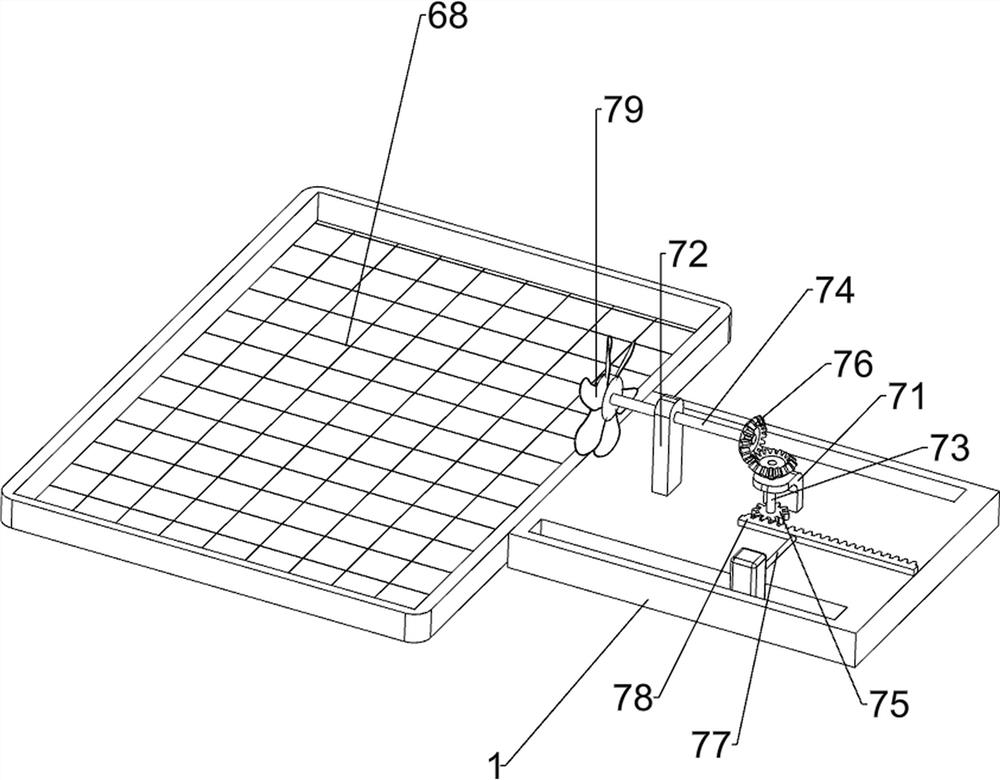

[0076] On the basis of Example 2, as Figure 4-Figure 7 As shown, it also includes a material blocking mechanism 4, the pressure plate 23 is provided with a material blocking mechanism 4, and the material blocking mechanism 4 includes a third connecting rod 41, a first fixing block 42, a second telescopic assembly 43 and a material blocking plate 44, The top of the pressing plate 23 is provided with four third connecting rods 41 , the four third connecting rods 41 are all provided with first fixing blocks 42 , and the bottoms of the four first fixing blocks 42 are all provided with second telescopic components 43 . A baffle plate 44 is connected between the two second telescopic assemblies 43 .

[0077] When the pressing plate 23 moves downward, the pressing plate 23 drives the third connecting rod 41 to move downward, thereby driving the first fixing block 42 to move downward, thereby driving the second telescopic assembly 43 to move downward, and the second telescopic assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com