Chemical auxiliary production device with dust falling function and using method

A technology for production equipment and dust reduction, which is applied to chemical instruments and methods, separation methods, and the use of liquid separation agents, etc., which can solve the problems of large dust volumes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

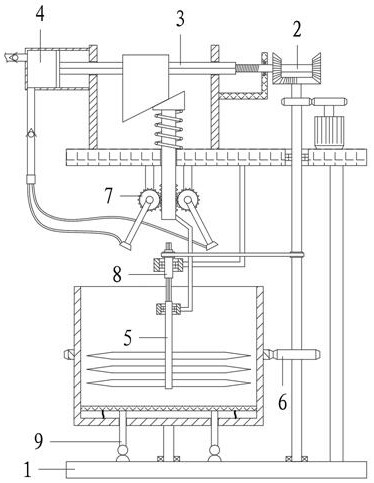

[0060] With reference to the accompanying drawings, a chemical auxiliary production equipment with dust suppression function includes a frame assembly 1, a drive assembly 2, a reciprocating assembly 3, a dust suppression assembly 4 and a crushing assembly 5;

[0061] The frame assembly 1 includes a base 101, a side plate 102, a top plate 103, a crushing box 104, a discharge pipe 105 and a support shaft 106; the right end of the base 101 is connected with a side plate 102, and the top of the side plate 102 is connected with a top plate 103; A shaft 106, the top of the support shaft 106 is connected with a crushing box 104; the bottom of the crushing box 104 is connected with a discharge pipe 105, and the discharge pipe 105 is equipped with a valve;

[0062] The top plate 103 is provided with a driving assembly 2, and the left side of the driving assembly 2 is equipped with a reciprocating assembly 3; Cooperate with the swing assembly 7; the crushing box 104 is provided with the...

Embodiment 2

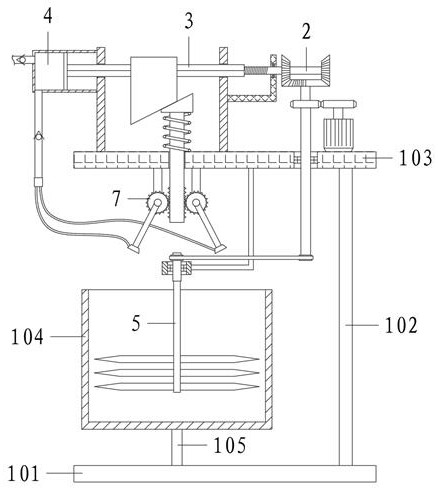

[0064] With reference to the accompanying drawings, a chemical auxiliary production equipment with dust suppression function includes a frame assembly 1, a drive assembly 2, a reciprocating assembly 3, a dust suppression assembly 4 and a crushing assembly 5;

[0065] The frame assembly 1 includes a base 101, a side plate 102, a top plate 103, a crushing box 104, a discharge pipe 105 and a support shaft 106; the right end of the base 101 is connected with a side plate 102, and the top of the side plate 102 is connected with a top plate 103; A shaft 106, the top of the support shaft 106 is connected with a crushing box 104; the bottom of the crushing box 104 is connected with a discharge pipe 105, and the discharge pipe 105 is equipped with a valve;

[0066] The top plate 103 is provided with a driving assembly 2, and the left side of the driving assembly 2 is equipped with a reciprocating assembly 3; Cooperate with the swing assembly 7; the crushing box 104 is provided with the...

Embodiment 3

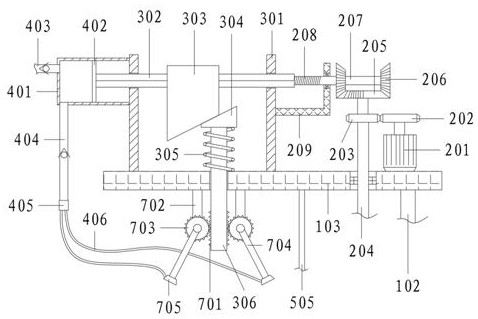

[0083] The difference from Embodiment 2 is that the crushing assembly 5 of this embodiment can move up and down synchronously, so as to change the action area of the crushing knife 507 and improve the crushing effect.

[0084] It also includes a lifting assembly 8; the lifting assembly 8 includes a spline shaft 801, a No. 2 support bearing 802 and a No. 2 connecting rod 803;

[0085]The rotating part 503 is a hollow shaft sleeve, the top of the installation shaft 506 is connected with a spline shaft 801, the spline shaft 801 passes through the hollow shaft sleeve upwards, and the inner ring of the hollow shaft sleeve is processed with a slot corresponding to the spline shaft 801; the installation shaft 506 The top end runs through and connects to the No. 2 support bearing 802 , and the No. 2 support bearing 802 is connected to the reciprocating rod 306 through the No. 2 connecting rod 803 .

[0086] Specifically, the hollow shaft sleeve is supported by the No. 1 support bear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com