Adjustable raw material mixing and stirring device for electric power tube production

A mixing and stirring, adjustable technology, applied in the field of electric power, can solve the problems of general finished product quality, user inconvenience, inability to adjust the speed of the stirring shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

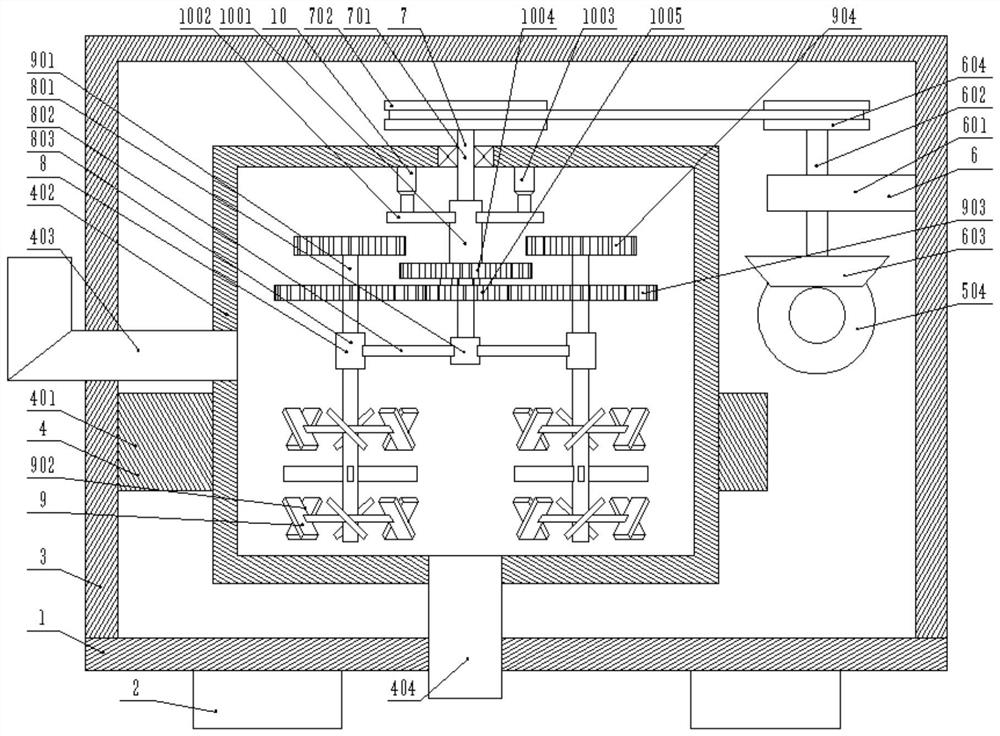

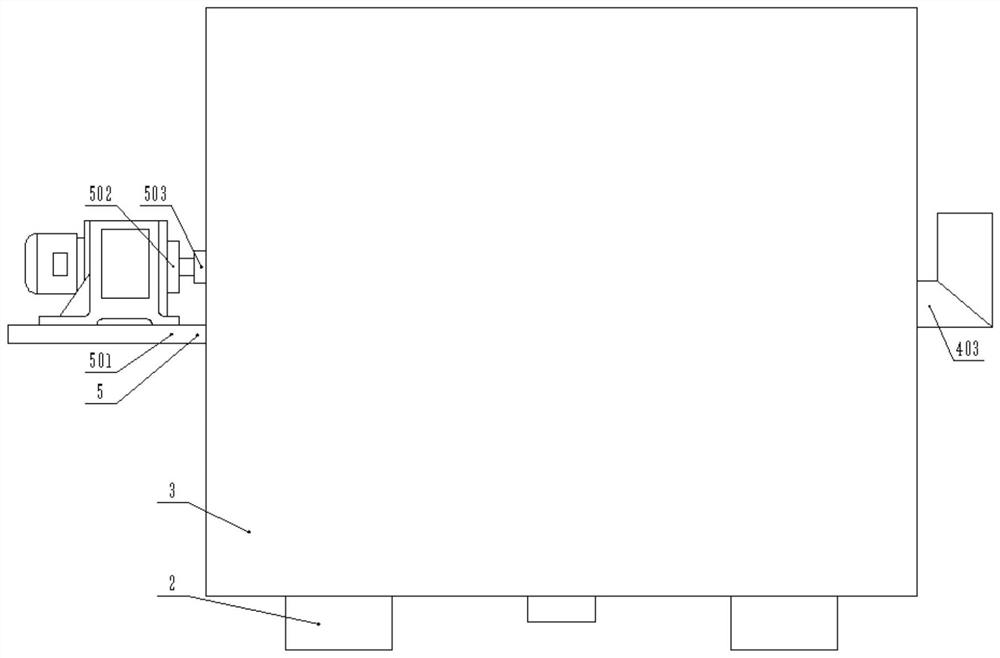

[0024] Example 1: Please refer to Figure 1-4 , an adjustable raw material mixing and stirring device for power tube production, including a base 1, a cushion block 2 is fixedly connected to the front, rear, left, and right below the base 1, and a box body 3 is fixedly connected to the top of the base 1;

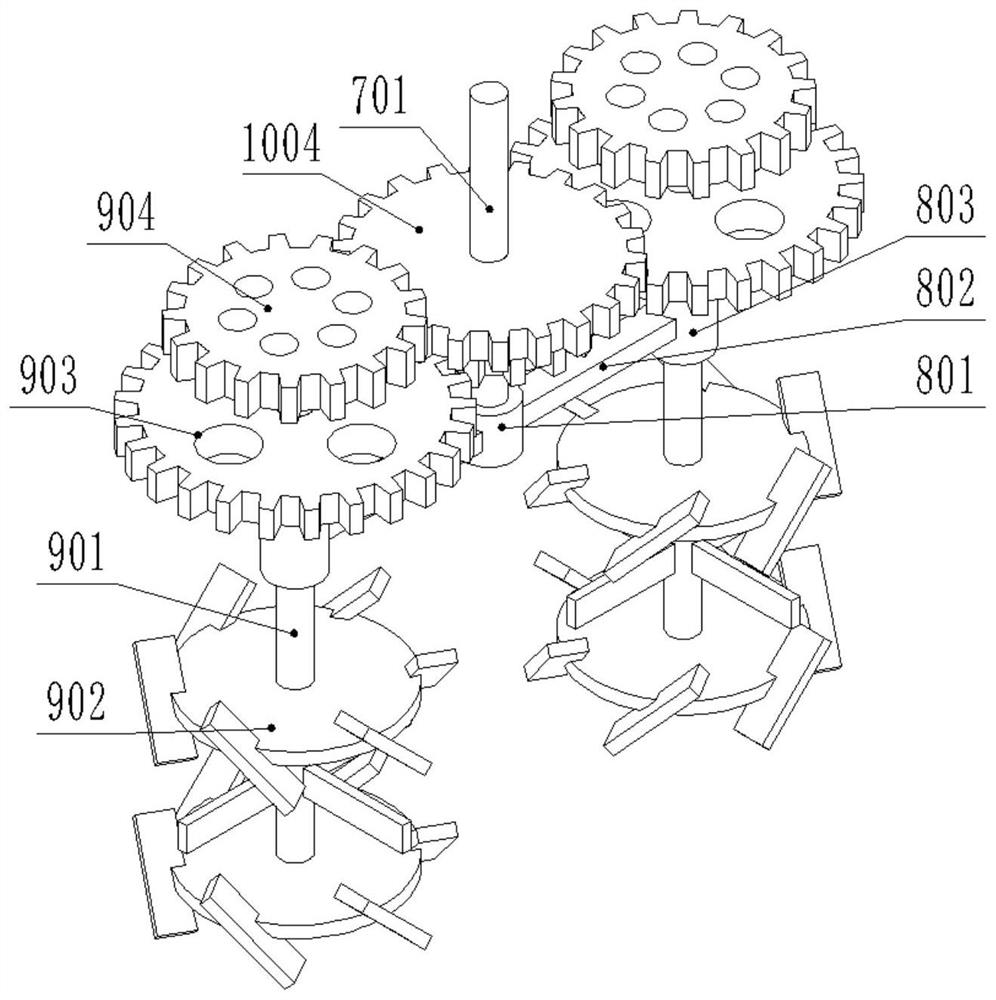

[0025] The box body 3 is fixedly connected with a fixing mechanism 4 under the middle part of the inner side of the left wall. When in use, the raw materials to be mixed are input into the mixing tank 402 through the feed pipe 403, the driving motor 502 is turned on, and the output end of the driving motor 502 rotates to drive The motor rotating shaft 503 rotates, and then the driving bevel gear 504 fixedly connected with it rotates, and then drives the driven bevel gear 603 meshed with it to rotate, and then drives the rotation of the driving wheel 604, so that the driven wheel 702 connected with the pulley transmission Rotate, and then make the rotating shaft 701 that is f...

Embodiment 2

[0037] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the connection method between the spacer 2 and the base 1 is welding.

[0038] The working principle of the present invention is: when in use, the raw materials to be mixed and stirred are input into the mixing tank 402 through the feed pipe 403, the driving motor 502 is turned on, and the output end of the driving motor 502 rotates to drive the rotation of the motor shaft 503, thereby making it fixed The connected driving bevel gear 504 rotates, and then drives the driven bevel gear 603 meshed with it to rotate, and then drives the rotation of the driving wheel 604, so that the driven wheel 702 connected with the belt pulley rotates, and then makes the rotating shaft fixedly connected with it rotate. 701 rotates, and then drives the fixed sleeve 801 fixedly connected with it to rotate, and then makes the connecting plate 802 fixedly connected with it rotate around the rotating shaft 701, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com