Automatic bundling device for logistics transportation parts

A bundling device and logistics technology, applied in the directions of transportation packaging, transportation and packaging, bundling materials, etc., can solve the problems of insufficient bundling and easy displacement of items, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

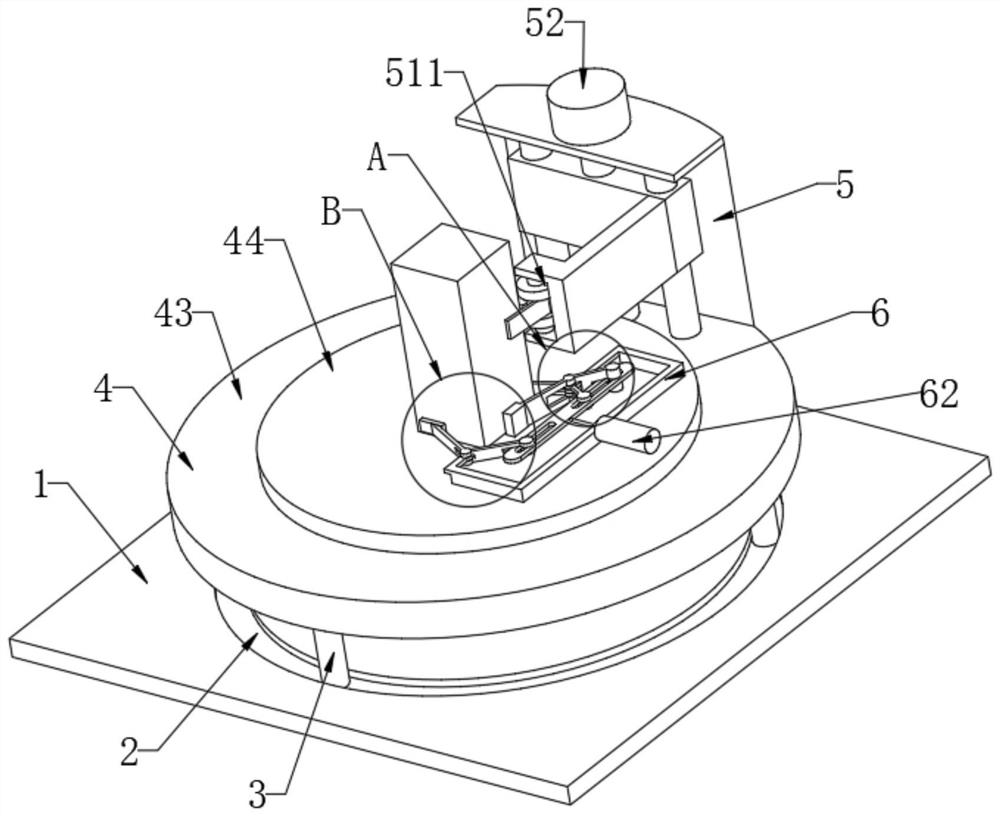

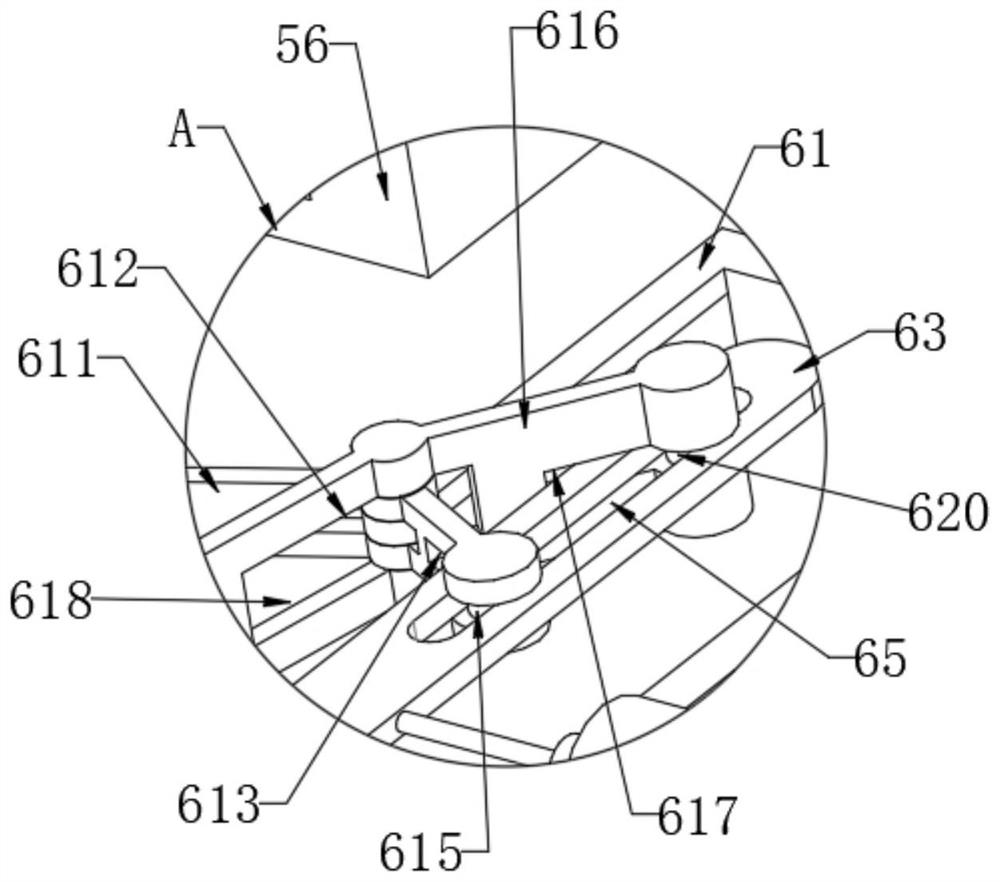

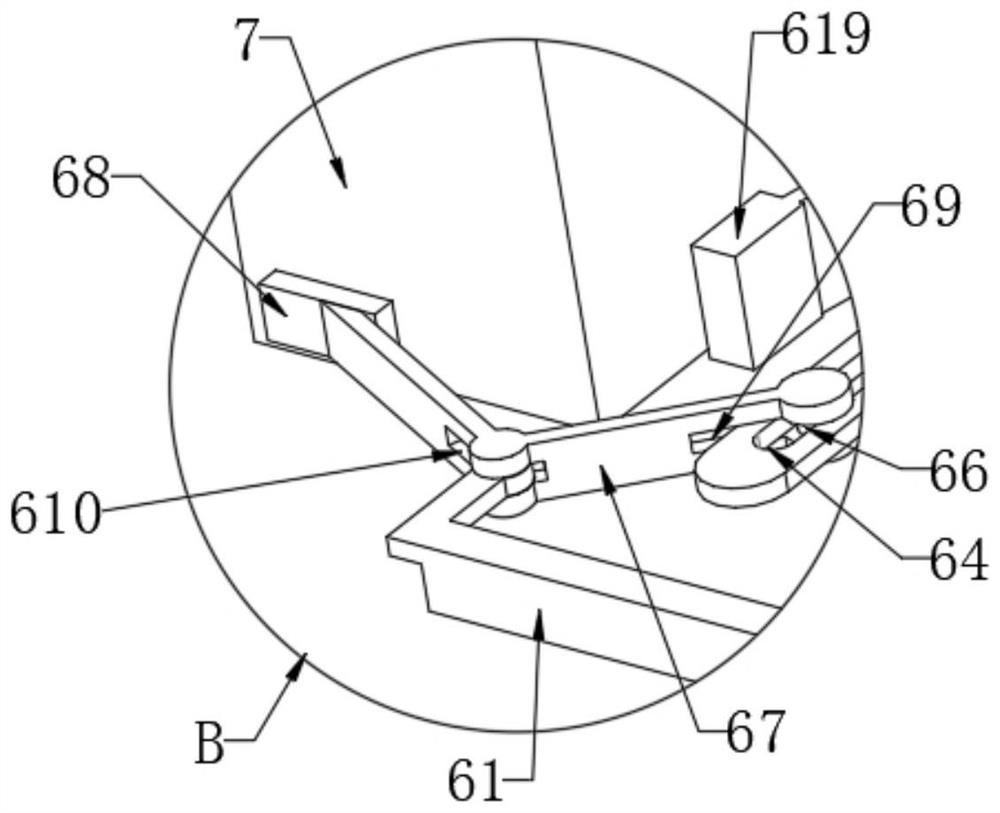

[0031] see Figure 1-6 , an automatic bundling device for logistics transportation parts, which is composed of a workbench 1, a rotating mechanism 4, a fixing mechanism 6 and a bundling mechanism 5.

[0032] Among them, the workbench 1 is used as a basic platform, and the upper surface of the workbench 1 is provided with a first chute 2, and the first chute 2 is slidably connected with the first sled column 3, and the first chute 2 and the first sled column are slidably connected to each other. 3 cooperate with each other to facilitate the normal operation of the rotating mechanism 4.

[0033] Wherein, the rotating mechanism 4 is fixedly connected on the surface of the workbench 1, the rotating mechanism 4 includes a first motor 41, the first motor 41 is a servo motor, the outlet end of the first motor 41 is fixedly connected with a support tube 42, and the upper end of the support tube 42 A turntable 43 is welded, and the middle part of the upper surface of the turntable 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com