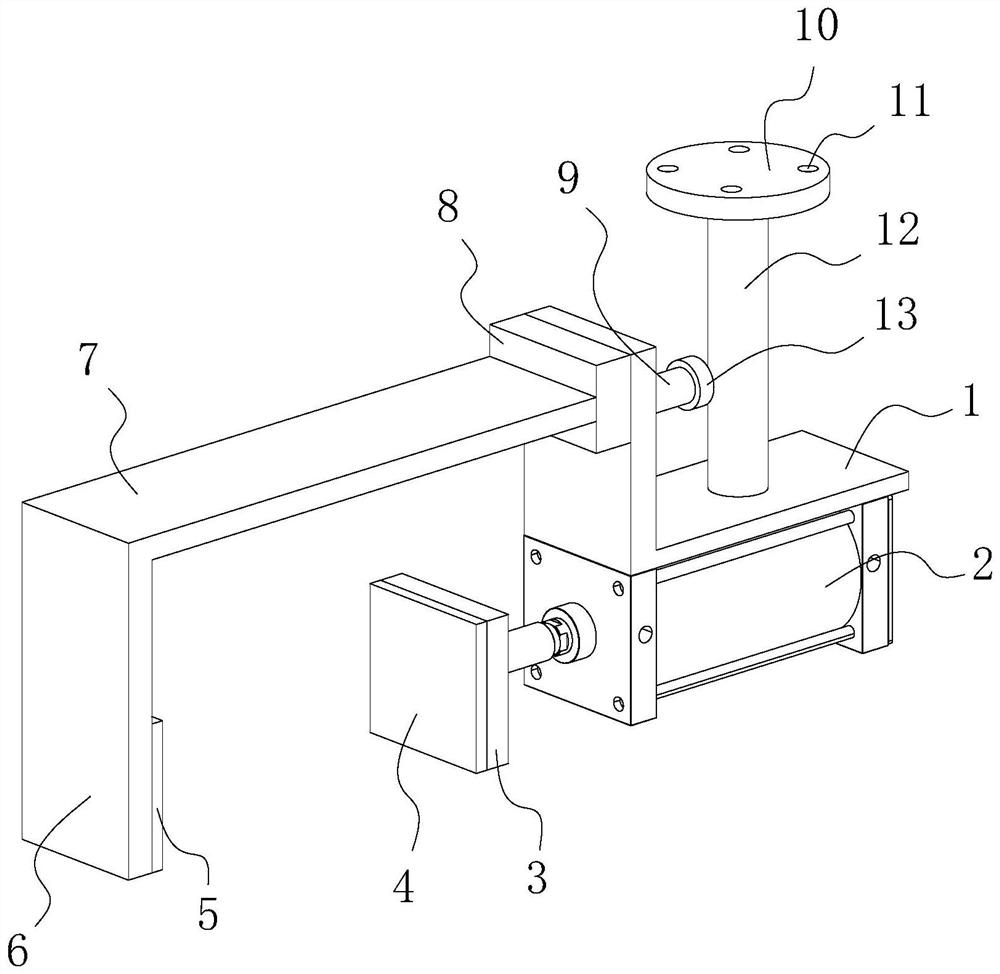

Transformer iron core clamping and carrying device

A transformer core and handling device technology, which is applied in the field of transformer production, can solve the problems of increasing the defective rate of transformer core production and damage of transformer core, etc., and achieve the effect of convenient cleaning, improving the yield rate, and reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

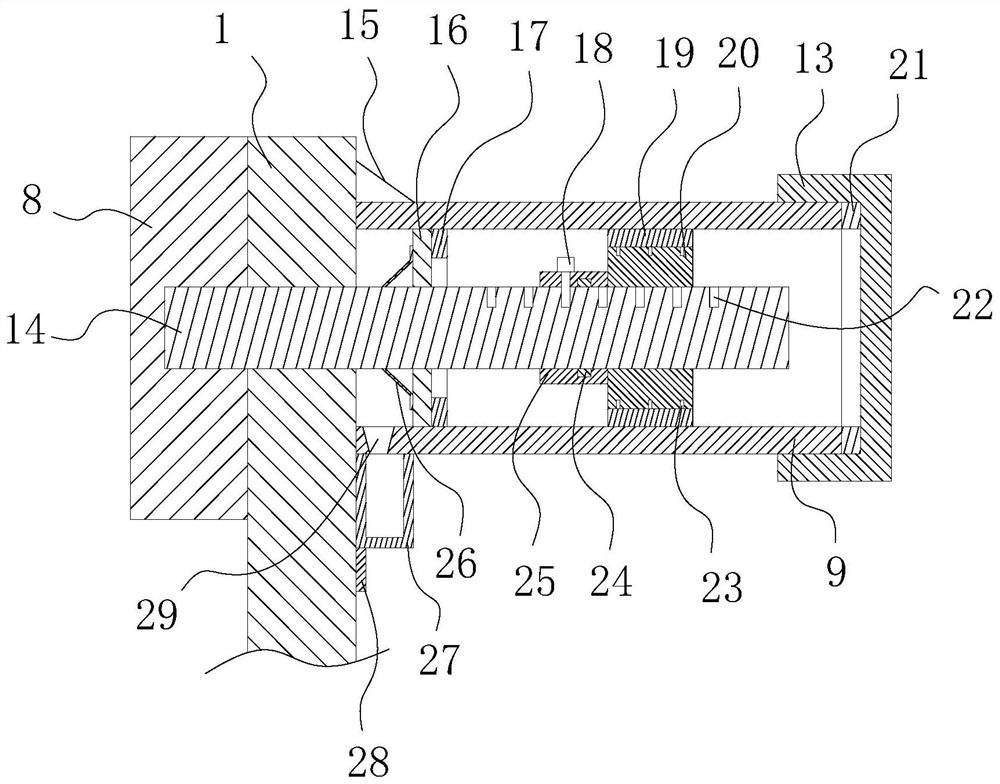

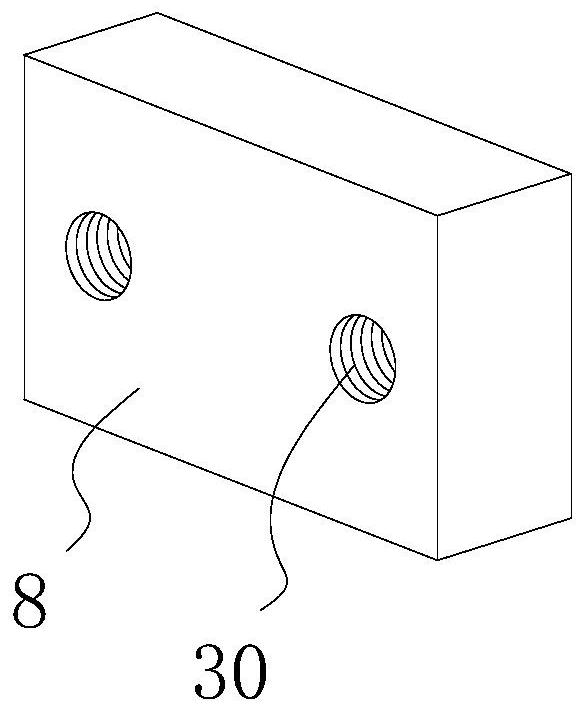

[0042] Specific implementation: Insert the two connecting rods 14 on the connecting seat 8 into the two cylinders 9 respectively, then screw the threaded cap 13 on the cylinder 9 to realize the blocking of one end of the cylinder 9, and then isolate the disc The ring 20 and the rubber ring 19 work together to divide the inner space of the cylinder body 9 into two parts. Since the gas volume between the isolation disc ring 20 and the threaded cover 13 remains unchanged, the isolation disc ring 20 is restricted under the action of the internal and external pressure difference. In the cylinder body 9 and does not slide randomly, the connection between the connecting seat 8 and the carrier plate 1 is realized. When the cylinder 2 drives the movable splint 3 and the fixed splint 6 to clamp the transformer iron core, it is affected by the reaction force of the transformer iron core. , the fixed splint 6 transmits the reaction force to the connecting rod 14 through the connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com