Forklift seat moving and overturning mechanism

A technology of turning over mechanism and seat, applied in the direction of movable seat, lifting device, etc., can solve the problems of heavy weight and bumping people, and achieve the effect of reducing labor intensity and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

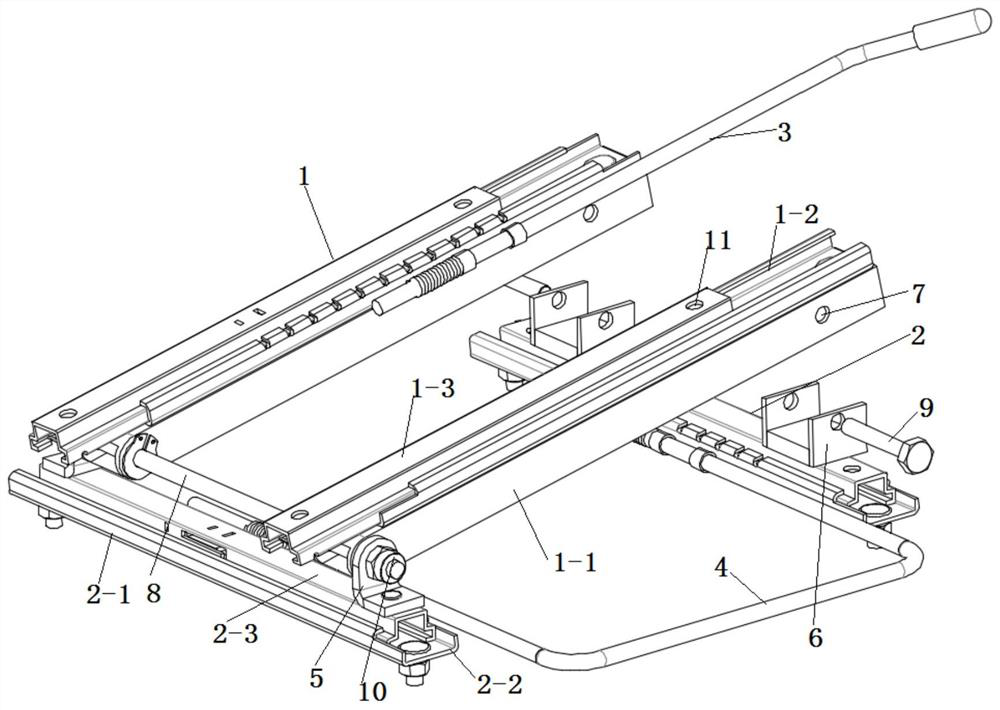

[0011] Such as figure 1 As shown, a moving overturning mechanism of a forklift seat includes two parallel upper slide rails 1 and two parallel lower slide rails 2, the upper slide rails 1 are located above the lower slide rails 2 and are connected to the lower slide rails 2 Vertical, on the upper slide rail 1 and the lower slide rail 2 are provided with corresponding upper chute handle 3 and lower slide handle 4 respectively, one end of the two upper slide rails 1 rotates with the top surface of one of the lower slide rails 2 The other ends of the two upper slide rails 1 are movably connected with the top surface of the other lower slide rail 2.

[0012] The upper slide rail 1 includes an upper slide rail base 1-1, an upper slide rail chute 1-2 and an upper slide rail slider 1-3, and the lower slide rail 2 includes a lower slide rail base 2-1, The lower rail chute 2-2 and the lower rail slider 2-3 are respectively fixed with positioning plates 5 on the top surface of both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com